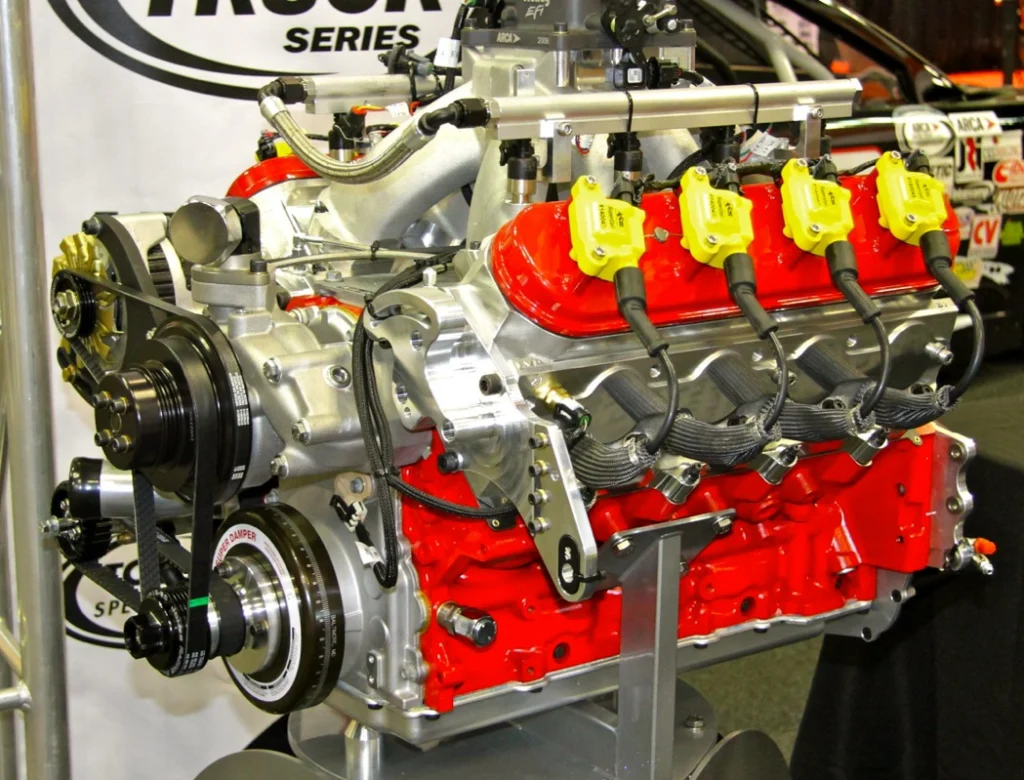

Ilmor Engineering, Inc. is a globally recognized provider of high-performance engines known for innovative designs that maximize power, durability, and efficiency. Engineering simulation is needed to continuously design new high-performance parts ready for races at short notice.

Complete system optimization of engine components including structural, thermal, and flow characteristics.

Developed a piston during race season and avoided high prototype costs by validating the design early at the simulation stage.

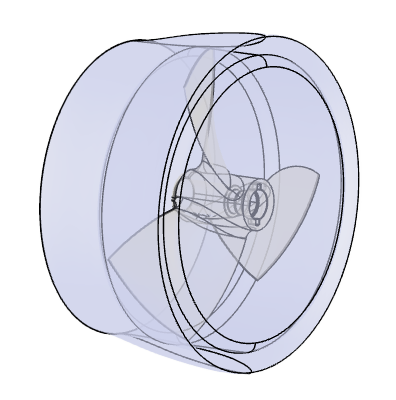

Innovated a novel ducted propeller design for marine applications.

The Simulation Team at Ilmor creates high-performance powertrains and components for the world’s leading companies. The award-winning team is known for its ability to innovate under immense pressure when the stakes are high during highly competitive racing seasons. Ilmor has invested in state-of-the-art research and development facilities that enable them to quickly discover solutions to the most challenging problems. Ilmor develops parts, sub-systems, and whole engines for most types of powertrains, from IC engines to E-machines across automotive, marine, and motorsport sectors. The wider Design Team works closely with the Simulation Team to ensure all designs are analyzed and optimized before moving to the manufacturing stage.

Creating compact, lightweight, and high-performance products that compete in championships globally requires a highly skilled team of experts backed up by industry-leading design tools. Andrew Richards is Director of Performance Business Development and has been with Ilmor Engineering for six years working primarily on the design and development of racing engines. Andrew and his team have implemented a successful design and development workflow combining CAE tools, including SimScale, that are used for fluid dynamics, mechanics, and thermal modeling which are all needed for the design and optimization of power units and their components. Measured test data is continually fed back to the Simulation Team to ensure the validity of the models and the accuracy of their predictions thus creating a complete design loop.

The Simulation Team acts as Ilmor’s virtual laboratory to support and optimize the design and development process. They use simulation for the design of marine and racing engine components. Parts are designed in Solidworks and then imported into Simscale for analysis. Analysis results are used to refine the design again in Solidworks and the cycle repeats until functional targets are met in the simulation. Simulations include static and dynamic FEA, incompressible fluid flow, and conjugate heat transfer. Simulation tools are complemented by a comprehensive metallurgical library of materials, heat treatments, and surface treatments developed by Ilmor from decades of experience. These material databases are added in SimScale so the correct material can be selected for even the most demanding applications and then simulated to verify performance.

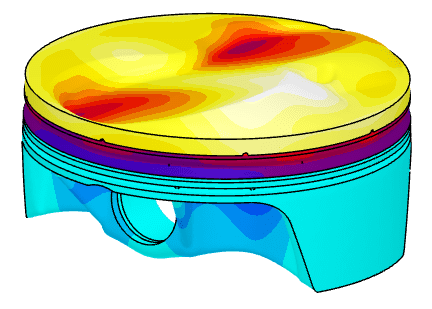

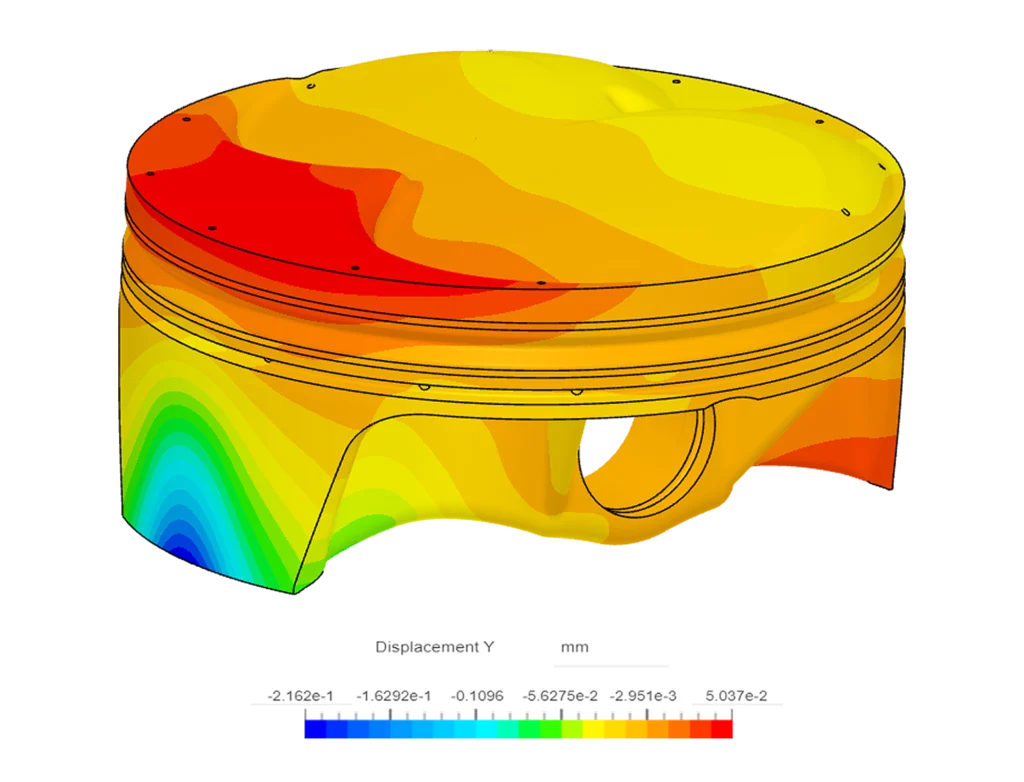

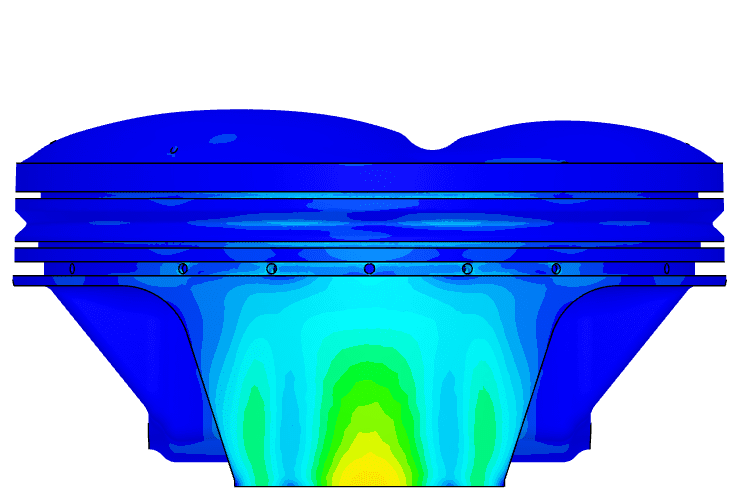

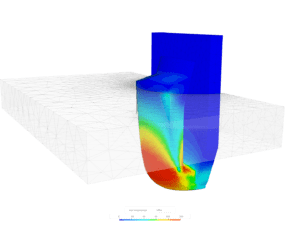

Ilmor designs and manufactures a myriad of high-performance, high-precision parts including pistons. The images below show a series of structural and mechanical analyses performed on an aluminum piston. Under various loads and forces, Ilmor can evaluate the stresses and displacement in the structure of the piston to make sure it complies with performance targets and the expected duty cycle. Once the simulations have converged on an acceptable design, it then progresses to the physical prototyping stage. By simulating early and often in the design process, Ilmor can disqualify poor design candidates at a much earlier stage of the design process and save time and cost during testing and manufacture.

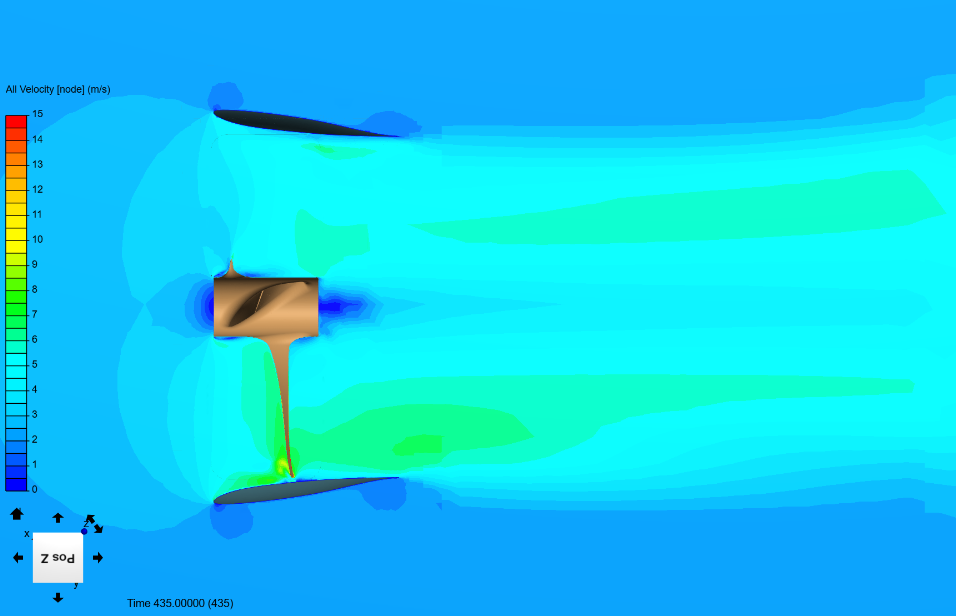

A recent example of applied CFD is the design of a novel ducted propeller for marine application. In this case, Ilmor extensively leveraged the parametric and cloud computing benefits of SimScale by creating a design model with various CAD parameters that could be varied easily. The study provided results for each case in terms of torque and power requirements and the total thrust generated by the propeller and the duct combination.

The gap between the propeller and the duct is important for the efficiency of the system due to the propeller tip vortex. SimScale was used initially to study the differences between different tip clearances between the propeller and the duct. Additionally, the incoming flow into the propeller plays a crucial role in the performance. The application for this ducted propeller required it to be capable of being tilted up to 60° angles vertically. The change in performance of the system was analyzed for the ranging tilt angles of 0°- 60°.

Each of these conditions was easily run under multiple scenarios of different propeller speeds (RPM) and incoming flow speeds. This provided a fast comparison of the performance of the ducted propeller system.

SimScale has provided Ilmor Engineering with accurate simulation of both structures and fluid flows that has resulted in reduced time in the prototype phase leading to final designs which are more refined than a strictly empirical development process would yield.

Additionally, SimScale’s intuitive cloud-based computing platform has expanded our complex simulation capabilities to all Ilmor designers, even those with minimal simulation experience. The high processing power inherent to SimScale allows for expedient simulation studies without the expense of dedicated workstations.

Andrew Richards

Director – Performance Business Development at Ilmor Engineering

Sign up for SimScale

and start simulating now