3P Innovation is an engineering and automation company based in Warwick, UK. Since 2006, 3P Innovation has been a trusted partner for multinational clients seeking to accelerate their product or production process from concept to commercialization in the global pharmaceutical, medical devices, and FMCG markets. 3P Innovation provides comprehensive support across development, production, and scale-up, ensuring the seamless transition of innovative products to market. Its core equipment portfolio is designed to support pharmaceutical clients at every stage of their product’s lifecycle. From early-stage drug development and clinical manufacturing to full-scale commercial production. A critical product for 3P Innovation is cryoFIL®, a Cryovial filling platform which is a lab-top, automated machine designed to automatically fill and cap cryovials. CryoFIL® is the world’s first GMP cryovial filling platform and is engineered to enhance cell viability and maximize yield. Engineering simulation has been extensively applied to design and optimize its performance, using SimScale.

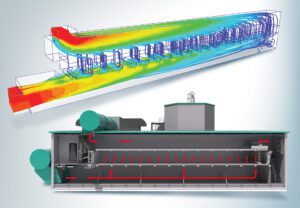

Jake Vermeulen MEng, is a Project Engineer at 3P Innovation. The team primarily uses SimScale for CFD or flow simulations of sterile air within isolators to visualize the downflow around critical locations in a machine – such as where open (drug) products are present. They can then analyze the downflow patterns to identify regions of turbulence or stagnation around specific elements of the model, allowing the team to focus and iterate the design quickly to eliminate possible areas of contamination. Additionally, the team leverages CHT solvers in SimScale for heat transfer simulations in some areas of design to ensure they achieve an optimum temperature distribution, something that drugs are highly sensitive to. The workflow from Autodesk Inventor to SimScale is a simple step of importing CAD models into SimScale which are then ready to run using existing model, material, and simulation settings.

I joined 3P as a graduate mechanical project engineer 18 months ago where I have been able to work on innovative solutions for liquid and powder filling in the pharmaceutical sector. I have had exposure to many engineering projects including: designing modules for feeding notoriously difficult and cohesive powders; working on our fully automated roboFIL™ line; as well as performing fluid simulations for our cryoFIL® filling platform using SimScale – ensuring open drug product remains sterile inside the machine. SimScale has allowed us to iterate designs more quickly and to show how our products are market leaders in a very competitive global pharmaceutical market. Cloud-native simulations mean that we don’t have to use a dedicated PC to run simulations, saving costs and freeing up our time to focus on moving faster from the design stage to market.

Jake Vermeulen MEng

Project Engineer at 3P Innovation

In the rapidly growing Cell & Gene Therapy (CGT) sector, many processes remain manual, raising contamination risks from operator handling. The cryoFIL® system automates cryovial filling process and uses Controlled Rate Freezer (CRF) compatible racks, providing seamless integration. Cryovials are transferred from the rack to the filling module. Each vial is individually uncapped, filled, and recapped before being returned to its original position in the rack. The rack can then be placed directly into the freezer, eliminating the need for further manual handling of the vials. This process maintains the integrity of samples and reduces the risk of contamination.

SimScale has been used to evaluate flow patterns around open vials and around the filling needle at various inlet velocities and temperatures. The team looks for areas of stagnation and/or turbulence (specifically above the open product on the left side of the unit) to see where they can optimize to reduce these effects. Even minor turbulence effects might have a detrimental impact on the carefully controlled internal conditions the vials need to avoid contamination.

Using SimScale has enabled us to run large simulations during the day whilst freeing up computational resources and engineers’ time. The cloud-based simulations that SimScale offers, effectively running in the background, was one of the key requirements we had when looking to use CFD software and it allows us to continue using our desktops for other work. We can concurrently focus on module design and important calculations to move faster to physical prototyping and experiments. SimScale highlights the most important areas of the product design to focus on so when we do move on to physical testing, we are already confident in the design choices we made at the earlier stages.

SimScale’s customer support team has helped us to produce better results with advice on the function of different settings within the solvers as well as identifying which specific solver will produce the most accurate results for the specific use case we are attempting.

Jake Vermeulen MEng

Project Engineer at 3P Innovation

Sign up for SimScale

and start simulating now