Ingenium Aero Consultancy is a specialist engineering design and development provider with long experience in the Formula 1 (F1) industry, concentrating on aerodynamics, thermal analysis, and the use of computational fluid dynamics (CFD). A particular focus has been on powertrain packaging, consulting with multiple clients to design and optimize the performance of battery-electric applications. A leading global provider of electric drivetrain (eDrive) solutions, Saietta Group Plc (“Saietta’), has worked with Ingenium Aero Consultancy to deliver its innovative complete eDrive solutions.

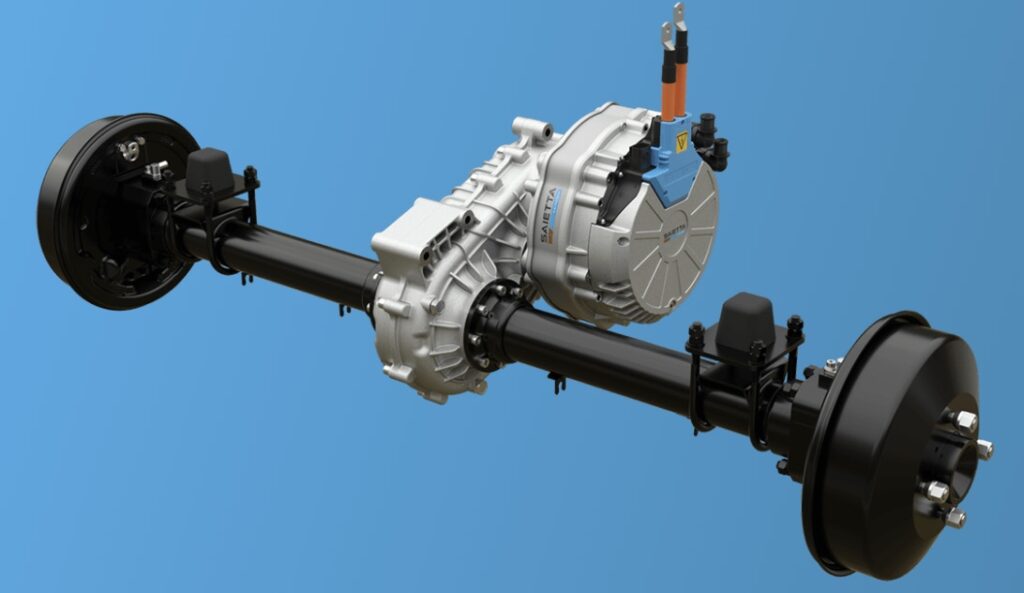

Saietta has engineered breakthrough electric motor technology including proprietary AFT (Axial Flux Technology) and RFT (Radial Flux Technology) which can be combined with in-house power electronics, powertrain controls, mechanical axles, and transmissions.

Airflow studies in many complex engineering scenarios have become an essential part of the early concept design. Aerodynamic design can lead to significant insights into passenger comfort, fuel efficiency (drag reduction), and enhanced stability of the design. Recent advances in computational methods and hardware, as well as wind tunnel testing technologies, have made the study of aerodynamics more accessible to understand complex airflow structures in a short space of time. Saietta engaged Ingenium Aero Consultancy with a particular need for thermal management in their new electric drivetrains. The original design wasn’t cooling correctly to within required temperatures and they needed a holistic analysis to make the component durable and reduce its weight and cost. Together, they have evaluated the performance of the motor in 2, 3, and 4-wheeled applications, with CFD used to predict aerodynamic drag and cooling performance, validated against real-world testing.

Peter Coysh was a lead aerodynamicist for McLaren, Mercedes, and Toro Rosso F1 teams, with over 20 years of experience in aerodynamic design, CFD, wind tunnel testing, powertrain integration, and vehicle data analysis. He has also developed the aerodynamics and thermal balance for helicopters, small boats, and a wide range of road vehicles. Peter uses SimScale, a cloud-native engineering simulation platform to analyze and optimize the performance of electric vehicles and their components such as drivetrains, batteries, and transmission.

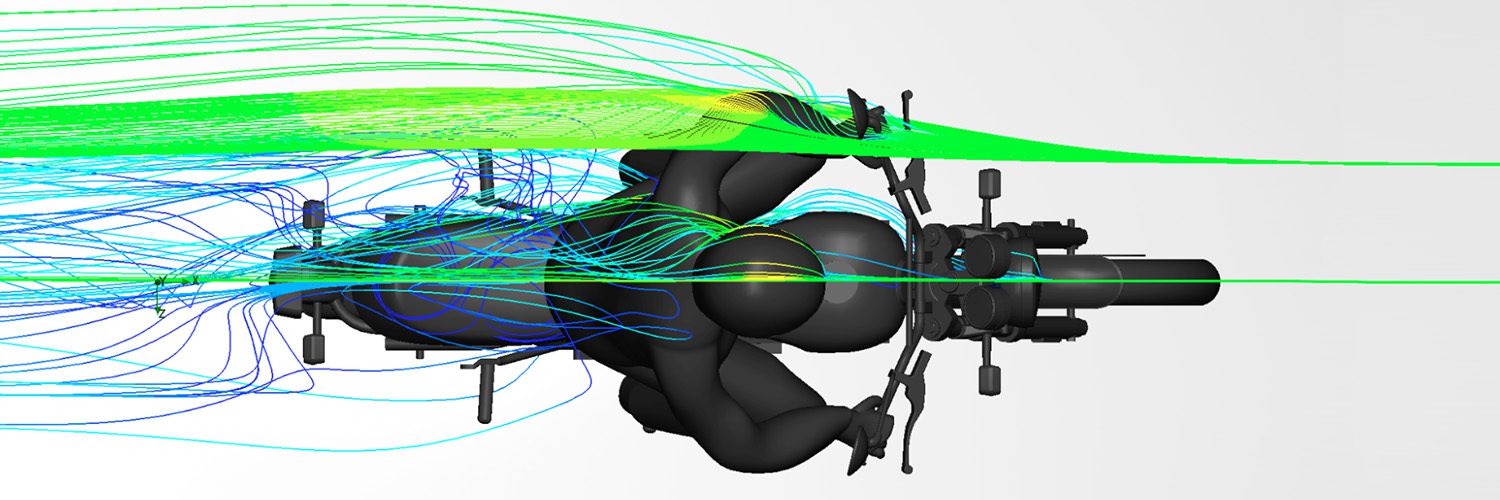

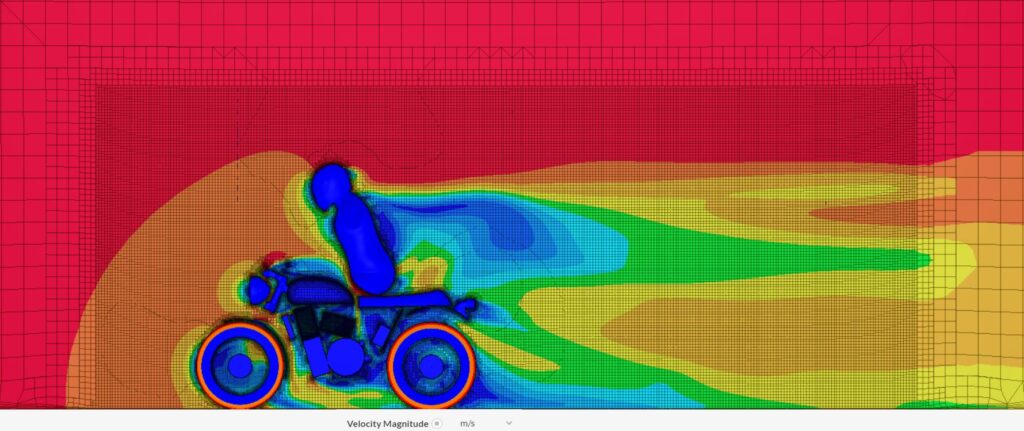

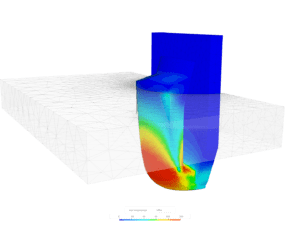

One of the first analyses Peter undertook using SimScale was CFD assessments of an e-motorcycle with a rider, modeled in CAD. This was to evaluate its aerodynamic performance accounting for the physical parameters of the bike and rider, to better evaluate the mechanical losses, and to validate the modeling. The team compared simulation results from SimScale to on-the-road testing and they were within <1% of each other, validating the SimScale approach and significantly reducing additional and costly wind tunnel and dynamometer tests.

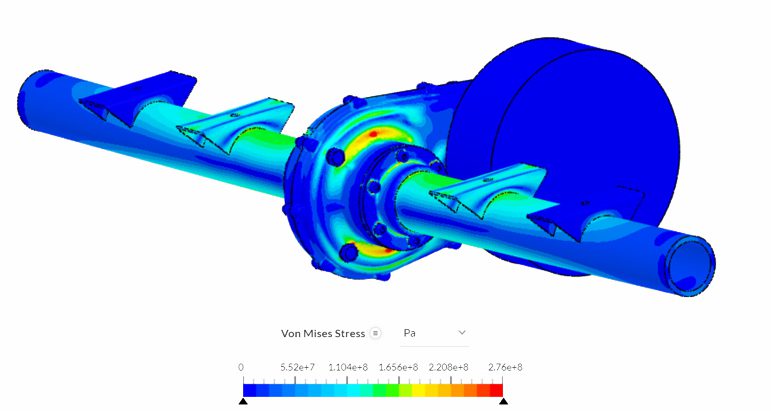

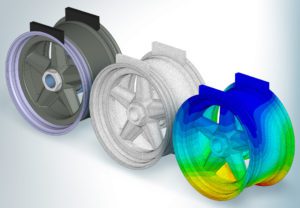

Peter’s engagement with Saietta encompassed the whole process from thermal design and development of the motor and inverter cooling, through to structural assessments and final design approval for the new AFT140 Axial Flux water-cooled motor and e-axle from concept to first deliveries in customer vehicles. The components individually tested included the motor, inverter, axle, and gearbox. Peter and his team are advanced CATIA users and importing complex CAD models into SimScale as STEP files was simple and allowed them to extract meaningful thermal and structural analysis results within a few minutes. The components are subjected to varying loading conditions whilst in operation and FEA was needed to predict structural risk to the motor. The team also performed harmonic analysis in SimScale to understand the risk from vibrations and resonance on the motor rotor, which was critical for user NVH and component durability.

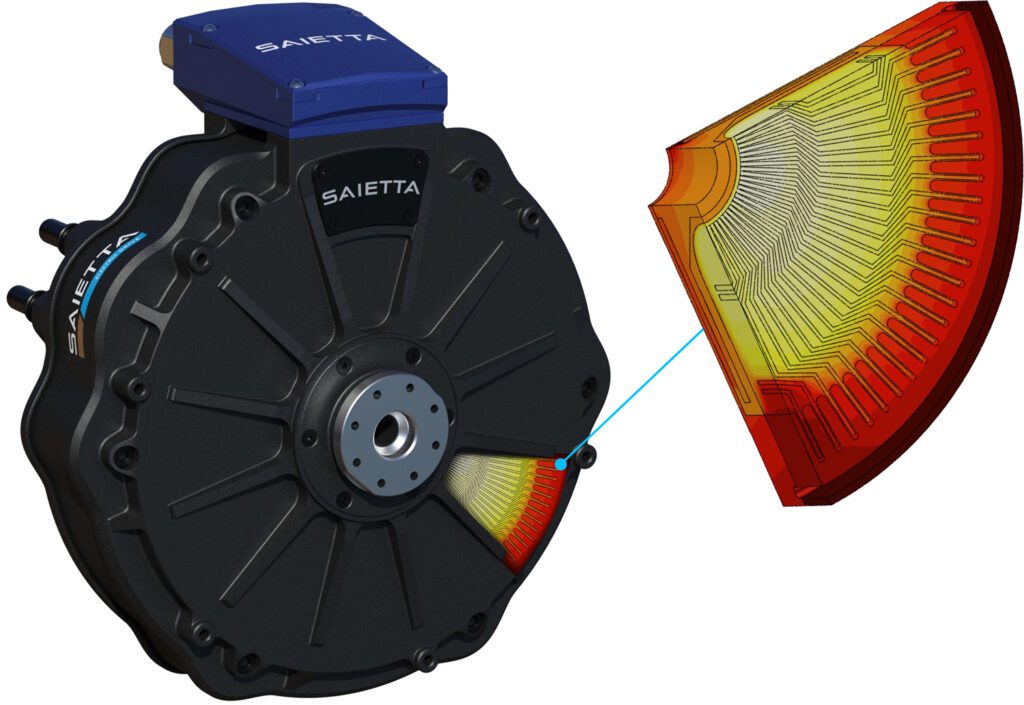

The motor can reach high temperatures and must be cooled to within safe operating limits. A CHT and thermo-mechanical analysis were used heavily to evaluate the thermal performance of the cooling systems as well as any thermal expansion that might damage the components. The images below show a segment of the circular motor under thermal analysis to predict peak temperatures and the distribution of heat under various operating and ambient conditions.

Peter and his team are making extensive use of SimScale to assist Saietta with developing innovative components and integrating them into a wider variety of vehicles. They were able to perform multiple types of analysis in a single platform with one CAD model, including thermal, thermo-mechanical, CFD, and structural with harmonic analysis.

Saietta now has the AFT140 motor and eDrive solutions in production, and Ingenium Aero Consultancy is assisting the development of class-leading water-cooled AFT motors, air-cooled RFT motors, inverters, and drivetrain solutions for a number of OEMs.

Using legacy tools we would have had to purchase several software packages and locally transfer/format CAD files continuously whilst being fixed to a workstation. Using the cloud-native features in SimScale, and the collaboration tools, we at Ingenium Aero Consultancy have access to a growing feature and physics set whilst accessing the software using a simple login from a web browser.

Peter Coysh

Aero-thermal Engineer at Ingenium Aero Consultancy

Sign up for SimScale

and start simulating now