Founded in 1979, Hazleton Pumps develops and manufactures heavy duty pumps and pump systems. With 40 years of industry experience, they design, build and service pumps in-house, catering to the specific requirements of their clients from across the world.

Rotating machinery design and analysis has high, and often non-negotiable, requirements for efficiency, durability, and reliability. With this goal in mind, the rotating machinery industry has widely adopted digital prototyping to explore a larger design space than is otherwise possible. But for too long, companies have been restricted in deriving the maximum benefits from digital prototyping due to the limitations of desktop-based legacy software, and Hazleton was no exception.

For the design and analysis of their in-house pumps, Hazleton relied on OpenFOAM for CFD and a number of third-party tools for CAD, meshing, and post-processing results. Their simulation workflow was time-consuming and cumbersome, with each step requiring immense manual effort. Project time and cost were further increased by desktop-based computations that did not scale up on-demand and required additional investment in high-performance clusters.

In need of a simulation tool to accelerate and optimize their design process, Hazleton turned to SimScale. This case study explores how Hazleton Pumps leveraged SimScale’s cloud-native rotating machinery technology to obtain fast and accurate fluid flow and performance assessments for their pump designs.

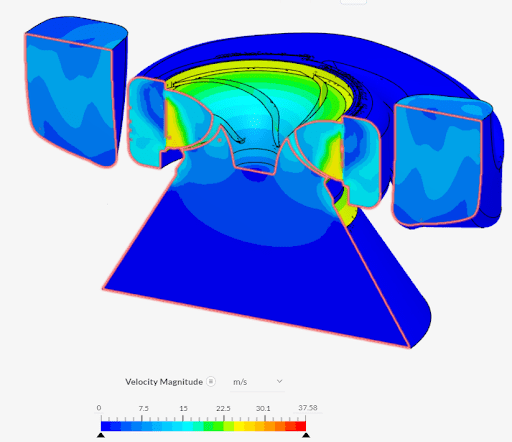

Having used OpenFOAM for about a year, and with little success, Hazleton’s Engineering Manager, Benjamin van der Walt, moved to SimScale in October 2021. Benjamin investigated three pumps using SimScale’s cloud-native technology for rotating machinery, which is capable of solving complex fluid physics for different speed regimes, with or without structural and thermal effects. This case study will focus on CFD studies for the small and medium-sized pumps, simulated using an incompressible steady-state approach and a RANS-based turbulence model. The primary objective of the simulations was to accurately calculate and benchmark the performance of the two pump designs.

I can't speak more highly of the SimScale simulation software. I am an avid believer in open source, but this just blew me over.

Benjamin van der Walt

Engineering Manager at Hazleton Pumps International (Pty) Ltd

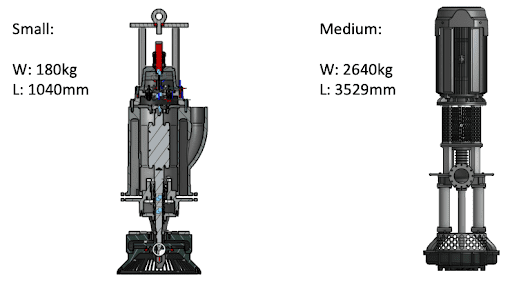

The first pump investigated by Hazleton was a 180 kg, 5.5 kW submersible, shown in Figure (1a).

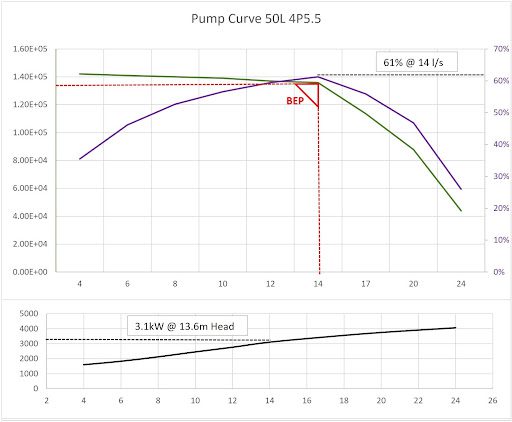

Through simulations in SimScale, they wanted to establish a baseline for the new impeller used in this pump and explore design improvements by analyzing the pump’s performance curve. Typically, a pump curve requires simulating a minimum of six input data points. In Benjamin’s experience, generating a solution for one input data point, using OpenFOAM’s transient AMI approach on a local HPC, took about three to six days. The time taken changed to about 9-15 hours with the steady-state MRF approach. This meant that generating a pump curve with six data points took up to a month and produced over a terabyte of data. Using SimScale’s cloud-native rotating machinery technology, Hazleton Pumps was able to produce the entire pump curve for this model in seven minutes, which is a 99.9% reduction in simulation time compared to OpenFOAM.

In rotating equipment design, solution accuracy is paramount and cannot be sacrificed for the sake of speed. To establish the accuracy of the fast results from SimScale, Hazleton simulated a second model, a 75 kW medium-sized vertical pump as shown in Figure (1b).

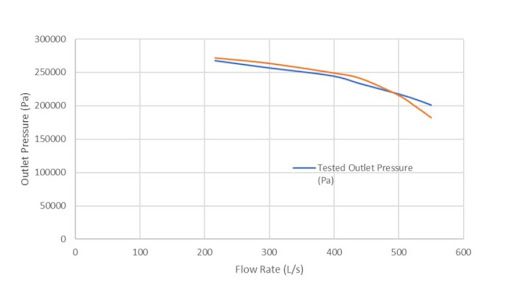

Hazleton tested the pump in their in-house test facility and generated pump performance data, as shown in the Figure above. The simulation set-up in SimScale was exactly the same as the test set-up, taking into account all the pump components like the inlet, impeller, volute, and discharge. Allowing for manufacturing differences and correcting for head loss observed in the pipes, the pump curve results from SimScale were within 2-3% error of test data, as shown in Figure (3) below.

In addition to expedited turnaround for accurate simulation of rotating equipment, SimScale’s proprietary technology also significantly improved Hazleton’s simulation workflow. With OpenFOAM, Benjamin’s workflow had been extremely complicated and he found the solution to be highly sensitive to the problem set-up and mesh, and therefore, unpredictable. He had to depend on a variety of tools for each step of the process. For example, he used Blender for pre-processing, ParaView for result visualization, and Excel for data analysis. With SimScale’s browser-based platform, Benjamin could perform all steps of the simulation seamlessly, without leaving the easy-to-use interface. Starting with a CAD model, he could generate the mesh, set up the simulation inputs, run a parametric sweep in parallel, and automatically plot the pump curve.

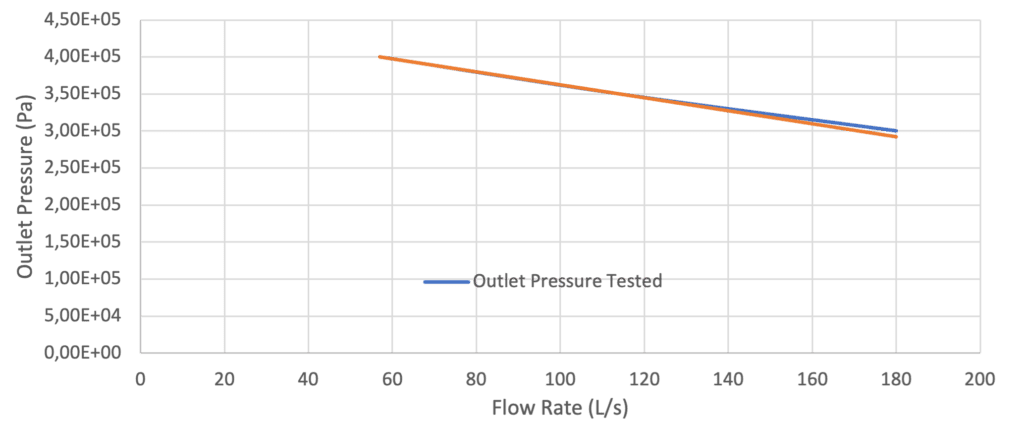

The third pump design of interest to Hazleton was a large 250 kW vertical pump, which in fact could not be tested on-premises and had to be taken to the South African Bureau of Standards (SABS). Each physical test at SABS cost Hazleton about $3000, not to mention the increase in time to market. With SimScale, they were able to simulate the same pump, from pre-processing to generating performance data, in only 23 minutes. When the accuracy of the simulation data was found to be within a 3% error margin of the SABS test data, as shown in Figure 4 below, it became clear to Hazleton that they could confidently replace expensive physical prototyping with simulation-driven design in SimScale for all their future pump designs.

So far, we have seen how Hazleton has saved money, as well as time, by using simulation-driven design in SimScale to accurately predict fluid flow and performance of pumps of various sizes. In Case 4, we show how Hazleton leveraged SimScale’s fast and accurate structural analysis to solve a problem with one of their installed pumps.

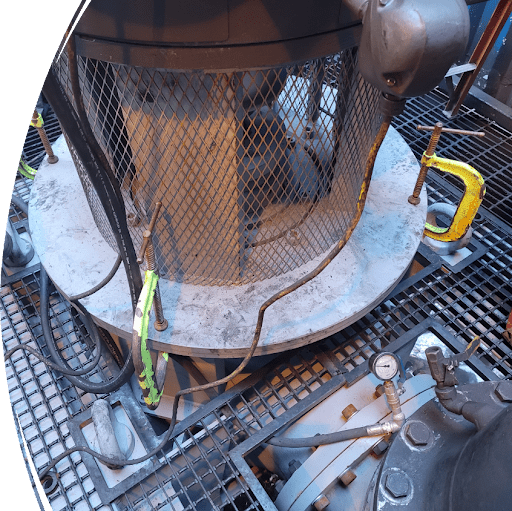

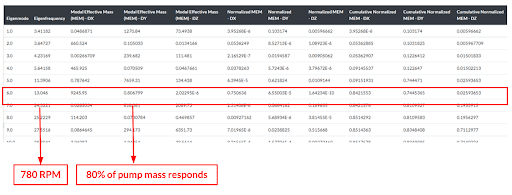

A large pump (about 9 tons in weight) was having vibrational issues at 800 rpm. Workers on-site added clamps to the motor bracket in the attempt to stop or limit the vibration and were only partially successful in doing so. Independent consulting engineers were hired on-site to try and understand the root cause of the vibrations and find a plausible solution. The pump in its installed environment is shown in Figure 5 below.

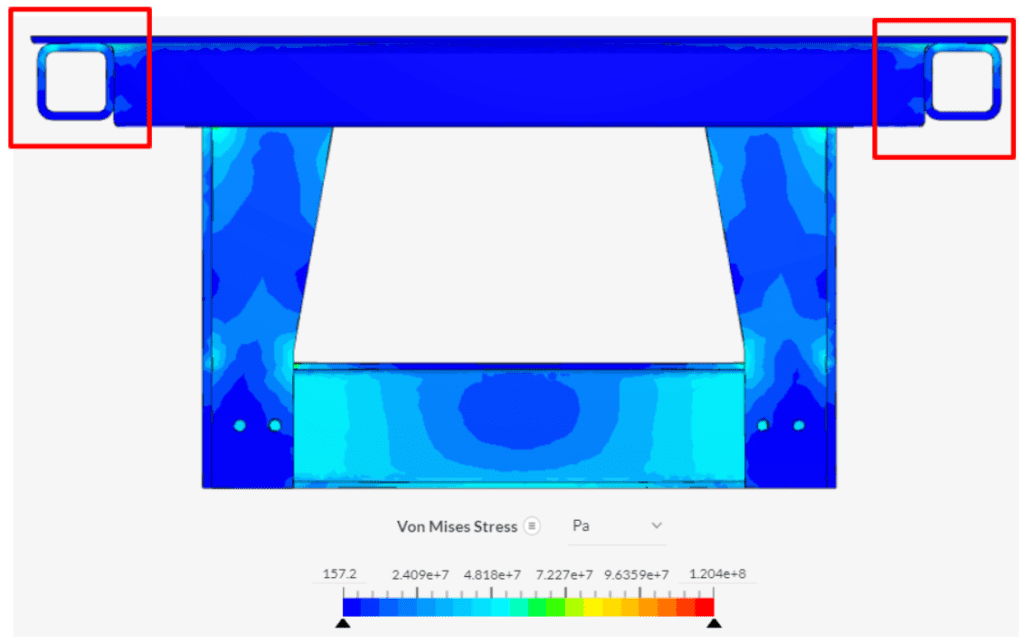

An on-site engineering report recommended the addition of 500 kg worth of steel reinforcements, additional support structures in the subframe, and changing the entire exterior bearing-to-shaft design. These design changes were estimated to cost $40,000 per pump ($200,000 for the five pumps on-site). Hazleton decided to use SimScale’s structural analysis capabilities to analyze the problem in detail. A multi-body modal analysis was conducted on the entire pump assembly. Results showed that the eigenfrequency of the structure was around 780 RPM and that at this speed, harmonic excitation was to be expected. Equipped with these insights from SimScale, Hazleton arrived at the decision to not run the pumps at speeds lower than 950 RPM to prevent failure. They also added cost-effective square tubing to the sub-frame on which the pump rested (as shown in Figure 6) at a fraction of the initial cost. This case study is a classic example of how multidisciplinary simulation can be leveraged to augment and even replace physical prototyping throughout a product’s lifecycle and help companies save time and money.

SimScale drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage) and simulation accuracy. It allows us to complete development cycles within days instead of months which gives us a massive advantage to our competition. I would say that this software is not evolutionary but rather disruptive. My recommendation to use SimScale for anyone in the engineering design space cannot be higher.

Benjamin van der Walt

Engineering Manager at Hazleton Pumps International (Pty) Ltd

Hazleton Pumps incorporated SimScale’s proprietary CFD technology for rotating machinery into their R&D cycle, with the goal of accelerating simulation-driven design of their in-house pumps. Taking advantage of SimScale’s cloud-native simulation architecture, Hazleton was able to generate performance pump curves within minutes, cutting their simulation turnaround time by ~100x compared to previously used tools. They also benchmarked results obtained from SimScale with experimental data from their test facilities and found our proprietary solver to be highly accurate and within 2-3% of test data. With the ability to host simulations and related data on the cloud, Hazleton completely eliminated their HPC and data management costs. Additionally, their simulation workflow was also tremendously simplified, thanks to SimScale’s browser-based, all-in-one software interface, which can be accessed from anywhere in the world through a simple login.

With such monumental savings in time and cost, Hazleton is now able to focus on designing and building better pumps, faster. SimScale is committed to providing cloud-optimized simulation solutions to Hazleton for further analysis of their in-house pump designs.

Sign up for SimScale

and start simulating now