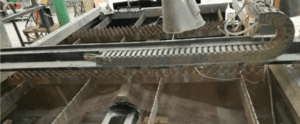

At Explotechnik AG, some of their solutions require a high-velocity piston to generate a shockwave. In order to slow down this piston, it needs to hit against a hardened steel surface. However, this design requires some testing before a physical prototype can be approved for production.

Before using CAE and SimScale, Explotechnik struggled getting their non-linear material properties at specified temperatures. This caused the piston to experience plastic deformation in their long-term experiments. This, in turn, led to different design iterations featuring different piston geometries and materials, to see which influences the changes had to the piston (stress-strain, plastic strain, etc.).

Through using SimScale, the team hoped to see a reduction in resources and cost by simulating different piston geometries and materials instead of running physical experiments.

Explotechnik AG incorporated SimScale into their workflow as their standard simulation tool. As a small firm, they didn’t have the capacity to have a local server in their office. Using SimScale, they were able to run all of their simulations from a PC in a web browser, saving resources, time, and physical space.

SimScale is a good and fast tool, especially if you want to run several simulations at the same time.

Reto Steiner

Research and Development Engineer

Through some typical trial and error, and by working with SimScale’s dedicated team of engineers, Explotechnik AG executed the necessary finite element analyses to evaluate their piston design. Their overall goal was to simulate different cases, and reduce the number of experiments needed.

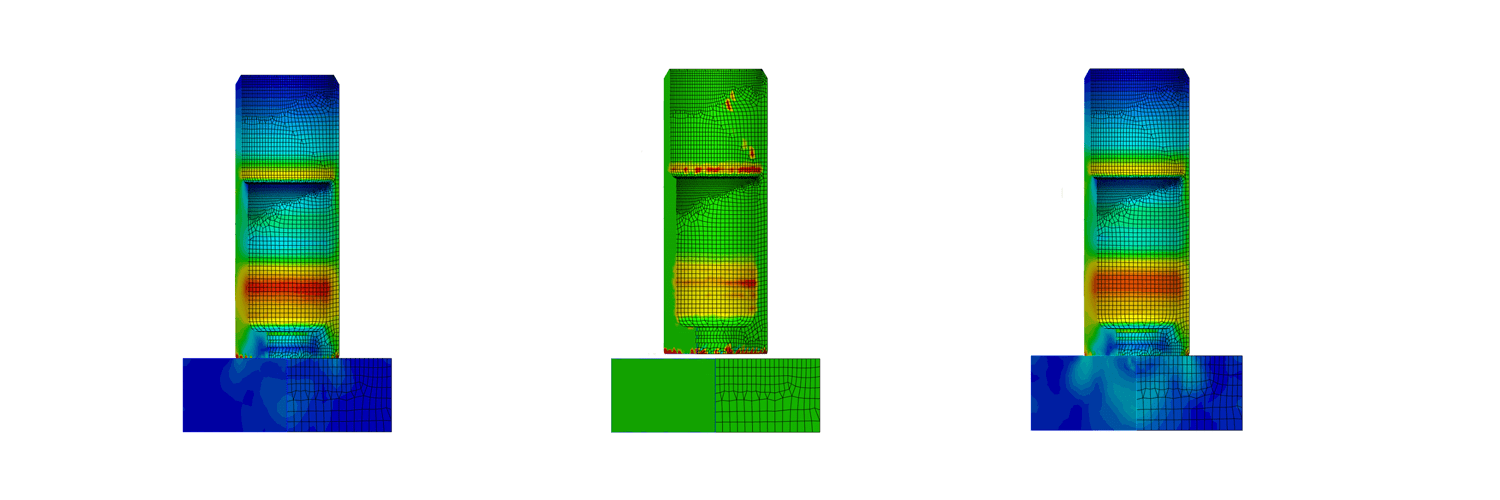

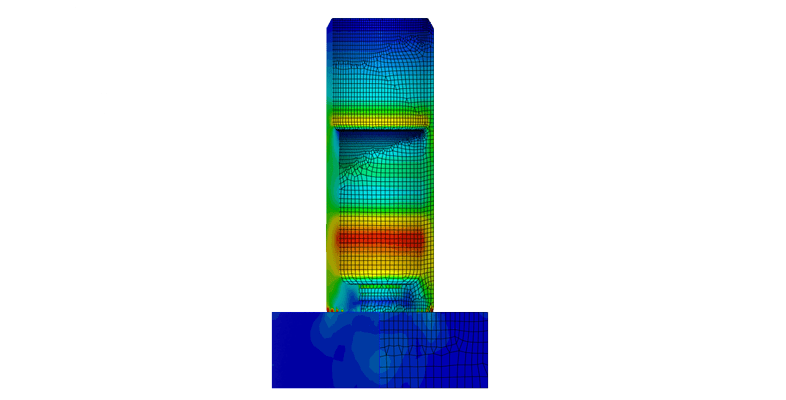

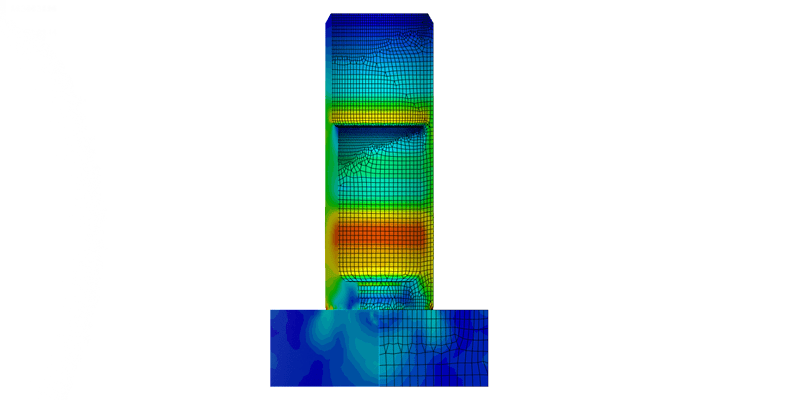

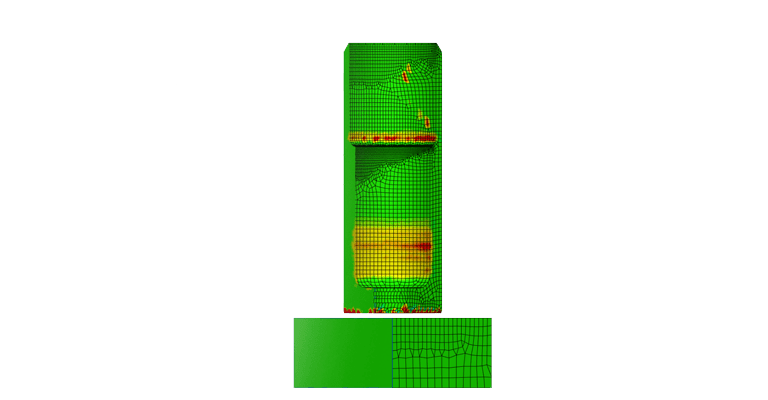

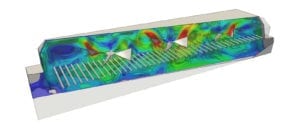

The team used tetrahedral meshes with allowed quad, ran a dynamic simulation using the Lagrange contact method, and used a nonlinear hyper-elastic material for their model. The analysis was performed both with and without friction.

When Explotechnik faced some initial challenges with simplifying the geometry while still getting valid results, they turned to SimScale’s support service as well as reviewed scientific papers to find the best simulation settings to get the desired results.

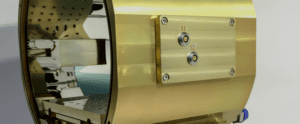

The team at Explotechnik was able to carry out the dynamic simulations for their piston design to completion, obtain results, and were able to quickly move on to the physical testing stage of their workflow speeding up overall development time for the new piston.

In total, the team ran about 10 simulations, on average using 200 core hours and lasting 200 min with 64 processors. The results collected from SimScale were then validated through a real-life experiment, which enabled them to move on to the production phase of their new piston design. In total, Expotechnik was able to save 1-2 weeks of experimentation, as well as physical prototypes and other tangible resources.

The fast and professional support offered by SimScale allows users to simulate complicated cases quickly, as well as master the FEA learning curve within the SimScale environment in a time-effective manner.

Reto Steiner

Research and Development Engineer

Since adopting SimScale into their workflow, the team has seen a reduced number of physical prototypes along with a significant decrease in development time, therefore, lessening costs. In the future, the team will easily be able to apply the same simulation settings to new piston designs, and additionally, save time. Here at SimScale, we look forward to continued collaboration with Explotechnik AG, and seeing what the future brings for them!

Sign up for SimScale

and start simulating now