Europack specializes in the design of custom-built thermal packaging for both the food and pharmaceutical industries. They strive not only to sell products, but to make their mark on the solutions they provide. Through Europack’s technical excellence the customer knows how their packaging works and can rely on it working, putting their products in the best of hands. Customer satisfaction is Europack’s guiding mantra.

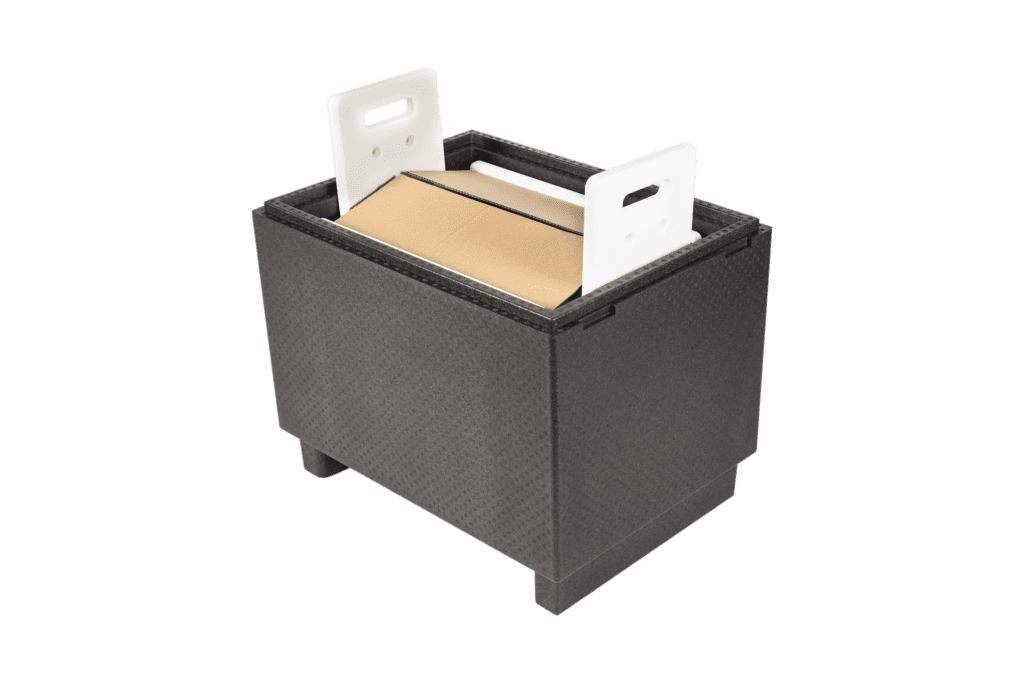

Europack’s commitment to sustainability comes with its own set of challenges. A client specifically requested a cooling box built only with biodegradable plastics and cooling elements. Europack needed to deliver a solution that would maintain the package between 2 to 8 C, ideally perfect 2 to 5 C, both in the hot danish summers and their cold winters. The solution would need to balance factors such as weight, the number of cooling elements, cost, and size to succeed.

We serve a diverse set of clients across a wide range of climates. SimScale and simulation are essential to our work so that we can have the confidence that our solution will fit our clients' needs before we commit to tooling that could cost over 100 thousand euros.

Peter Mailund

Europack

Europack had previously used external consultants to run simulations and evaluate their designs before this project. Yet, the sheer number of layouts that would be needed to be considered, as well as and the other pressing need for rapid iterative design, led Europack to bring simulation capabilities in-house. SimScale was a natural partner choice, since Europack did not want to invest and deal with the hassle of on-premises hardware, and SimScale was able to support the project with technical expertise.

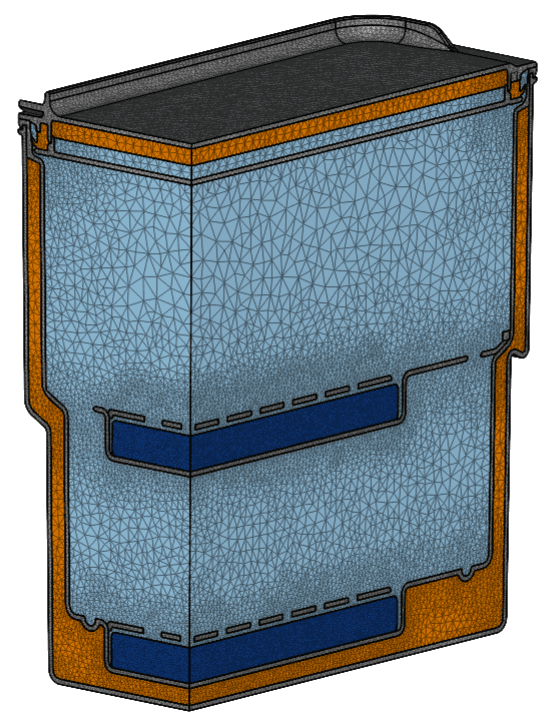

Using SimScale, Europack ran multiple transient thermal analyses evaluating a variety of different designs, using the performance of previous iterations to inform further optimization. Each simulation solved the internal temperature distribution of the cooling pack for a period of 36 hours. Europack was then able to quickly set up the needed simulations by using the setup of previous runs as a template for subsequent simulations. The boxes underwent thermal cycling representative of both summer and winter conditions, and being able to run both these cases in parallel Europack was able to cut overall simulation time by half. Each simulation ran on 64 cores and took 3 hours to complete compared to 3-4 days in a climate chamber.

The key result that the simulations provided was the temperature distribution within each cooling pack as a function of time. Counter-intuitively, Europack found that a PCM-based cooling element exhibited the best performance when compared to a water-based ice pack. Typically ice packs perform the best due to their higher phase change enthalpy, but because the packages were to be stored for a significant period of time at 2 C this enthalpy was being used from the onset of the cooling packs’ journey as the ice packs slowly melted. On the other hand, PCM packs have a melting point at 4 C, meaning that they remained frozen, and only when fully exposed to higher external temperatures did the phase change begin to occur.

Overall 25 different simulations were run, evaluating two different cooling element options along with a variety of wall thicknesses under winter and summer conditions. Being able to see the results of a design early and often helped inform further development and saved significant time when compared to external consultancy or using a climate chamber.

Europack has continued to use SimScale on a variety of projects since, running simulations on all their designs before committing to a physical prototype. Their current and future projects include design packages for Corona vaccines, and working on special packaging for blood samples, tissue samples. Europack serves clients from across Europe from the heat of Spain to the cold of Norway, so they plan to spend plenty of time validating their designs across these diverse climates.

Sign up for SimScale

and start simulating now