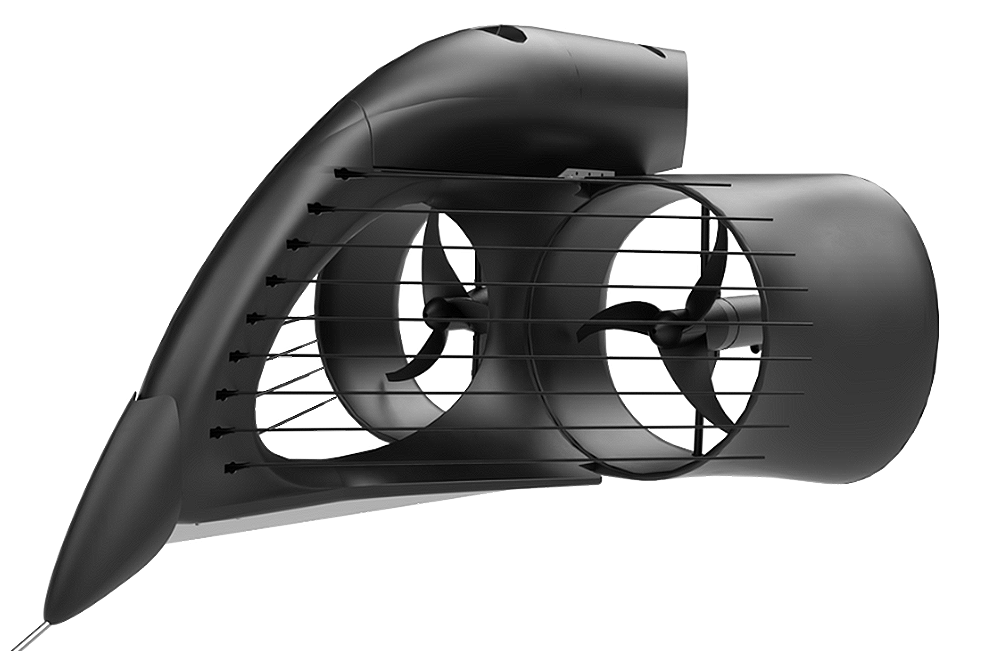

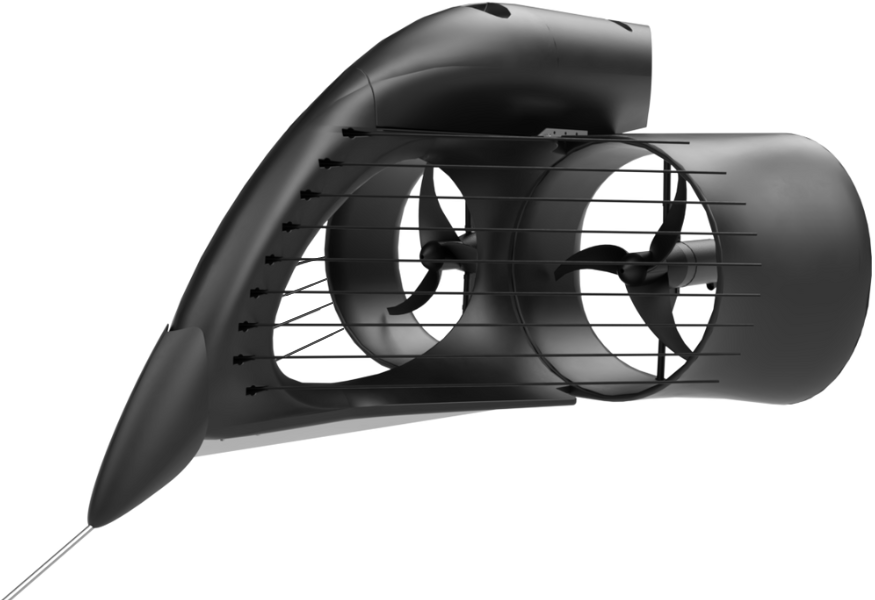

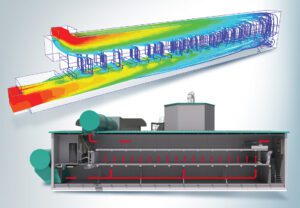

The Energyfish by Energyminer is a micro-hydropower plant that harnesses the power of water and produces electricity continuously in a river. Energyminer’s engineering team was looking to simulate and analyze the fluid-structure interaction, material selection, structural resilience, and turbine.

This case study presents an analysis of the Energyfish, an innovative micro-hydropower system developed by Energyminer. Utilizing the latest in engineering simulation through SimScale, the Energyfish exemplifies a breakthrough in harnessing riverine hydrokinetic energy. This study explores the intricate engineering processes, simulation techniques, and environmental considerations that underpin its design and functionality.

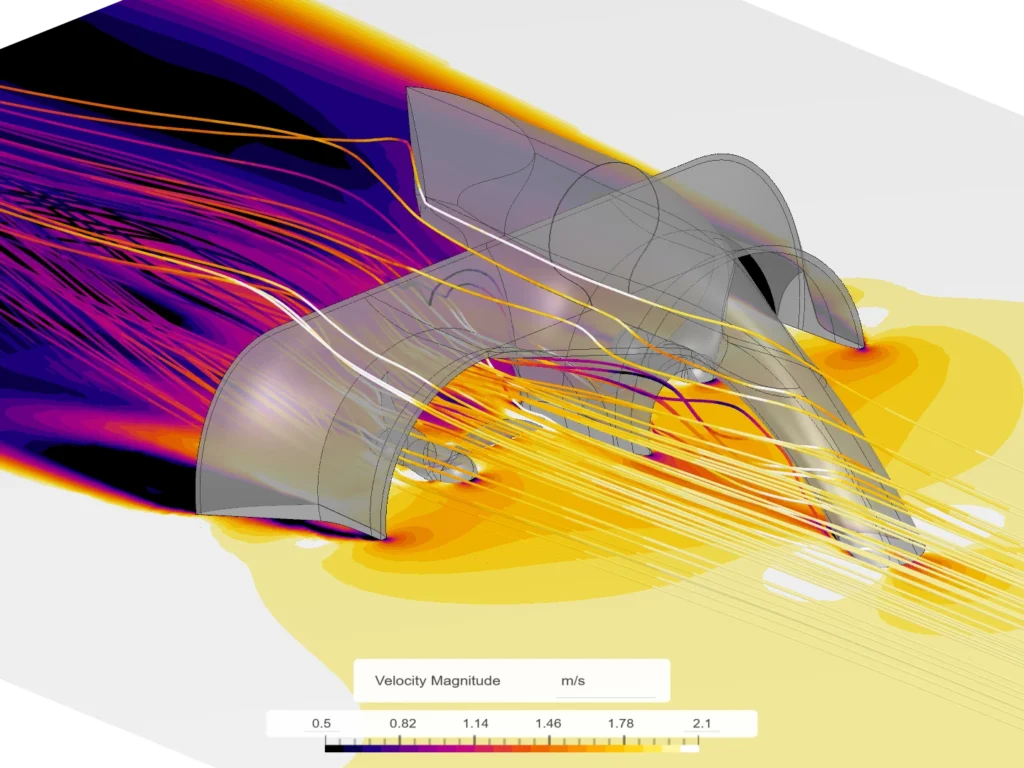

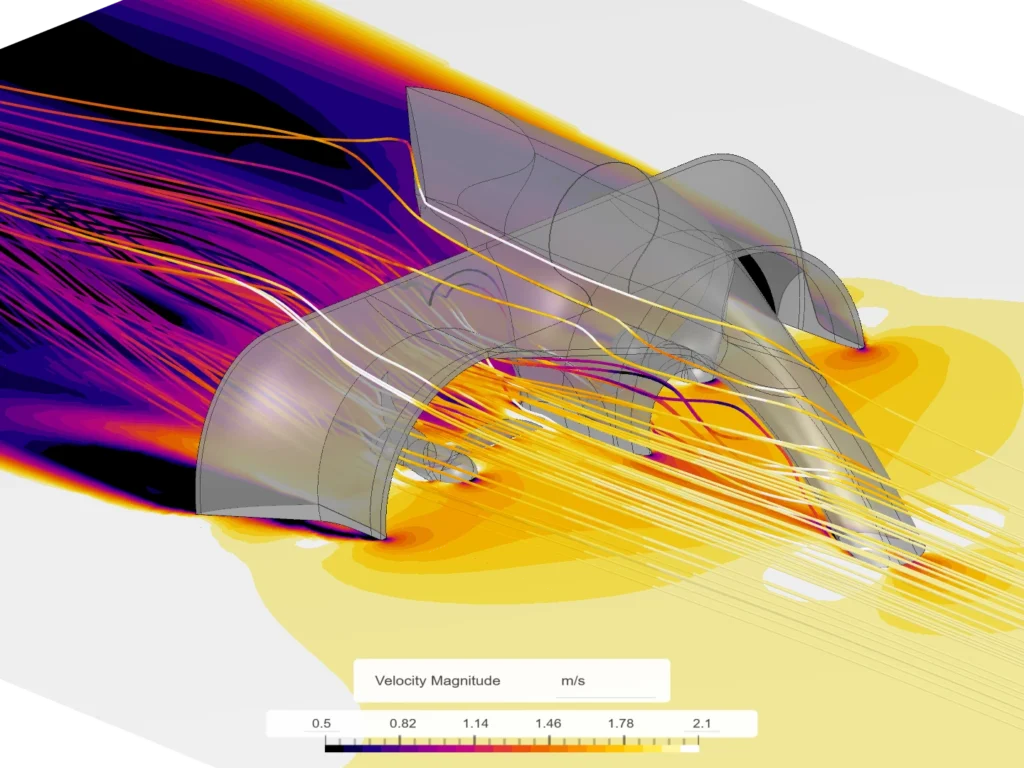

In the quest for sustainable energy solutions, the Energyfish emerges as a pioneering system. Unlike traditional hydropower, it operates unobtrusively within river environments, harnessing the kinetic energy of flowing water to generate electricity. Engineering simulation is used to refine the technical specifics of its design, including the optimization of hydrodynamic loading, structural stresses, turbine efficiency, and environmental impact assessments.

The Energyfish design philosophy centers on minimal environmental disruption and maximal energy extraction efficiency. The unit is predominantly submerged, with a low visual profile, ensuring minimal ecological and aesthetic impact. Key features include:

We have used SimScale to design the Energyfish energy system from first principles. Being able to simulate broad physics including turbine design, hydrodynamic loading, and structural deformations all in one platform in the cloud is a huge advantage to our product development process and to bringing the Energyfish to market.

Chantel Niebuhr

CTO at Energyminer

The Energyfish’s design incorporates several features to minimize ecological impact:

All the above features have had to be ‘designed-in’ using careful analysis to balance compromising competing performance requirements. Energyminer faced several engineering challenges including:

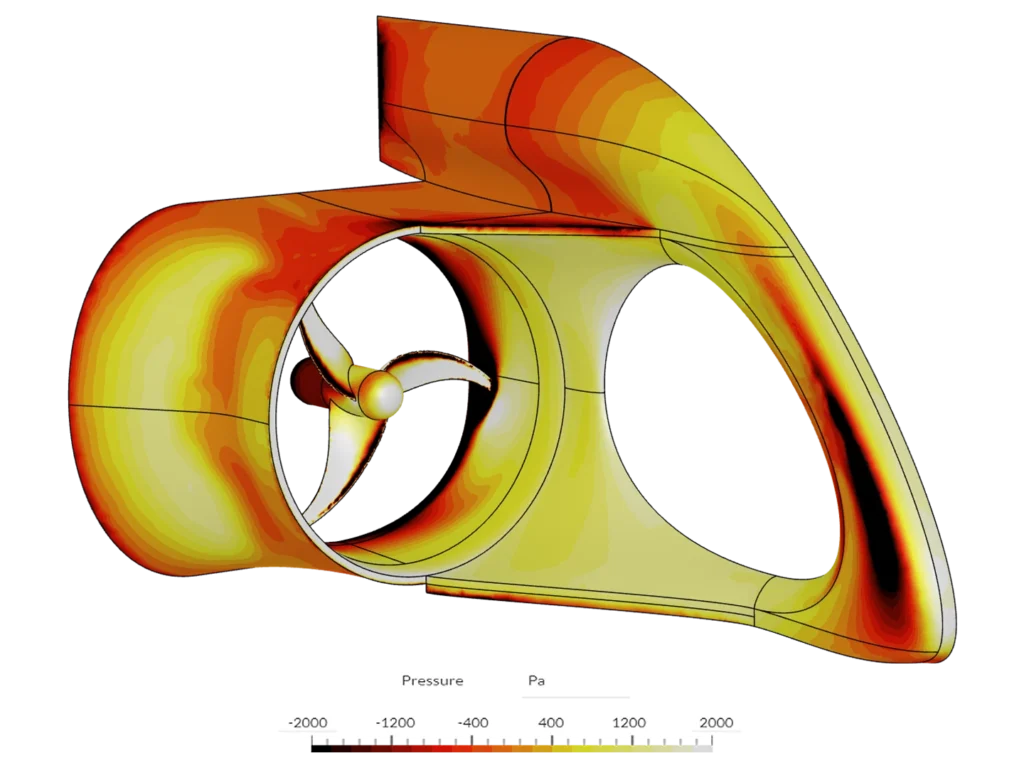

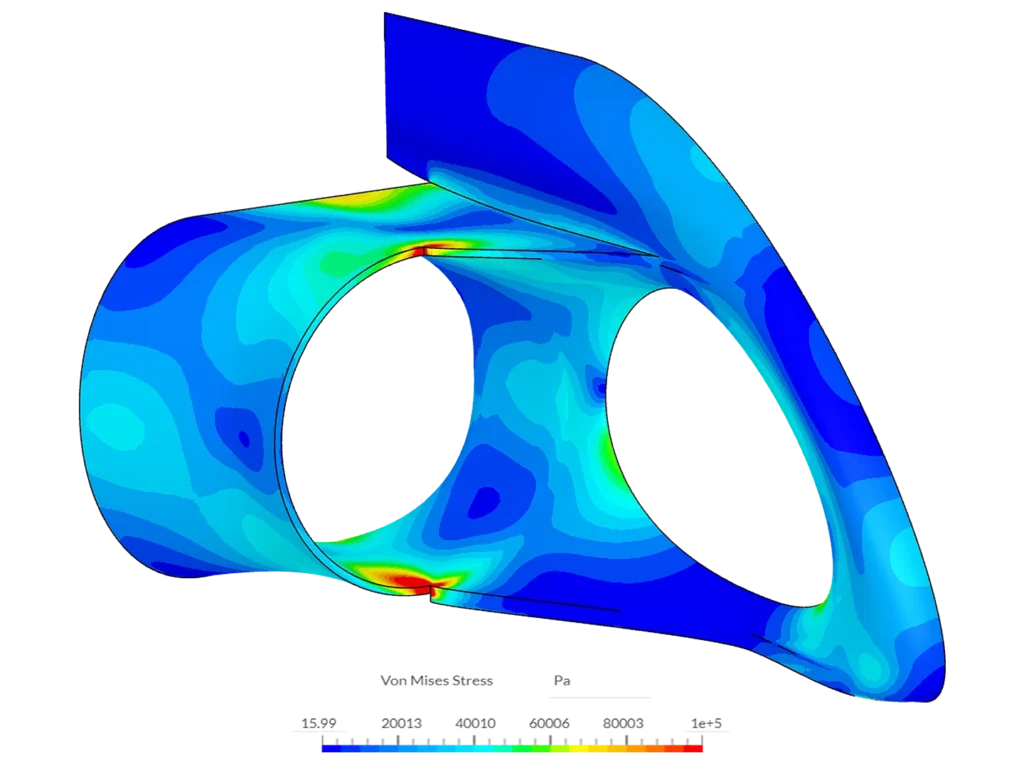

A simple workflow in SimScale is used for evaluating fluid-structure interaction in SimScale starting with a CFD flow analysis. The surface pressure results are then downloaded and used to create and apply a pressure 3D varying boundary condition as the input for a structural analysis using a CSV imported file.

The simulation workflow has yielded significant design insights for the structural and material properties used. The team at Energyminer wanted to include a small cut in the frame of the Energyfish to let it fill with water and improve buoyancy. It was important to predict what impact this might have on surface pressure:

Currently the Energyfish is undergoing extensive physical testing and pilot phase deployment and monitoring. Simulation work is progressing towards predicting transient effects, and understanding the impacts of vortex shedding and the layout of the units to capture the maximum energy from a river.

Chantel Niebuhr

CTO at Energyminer

Sign up for SimScale

and start simulating now