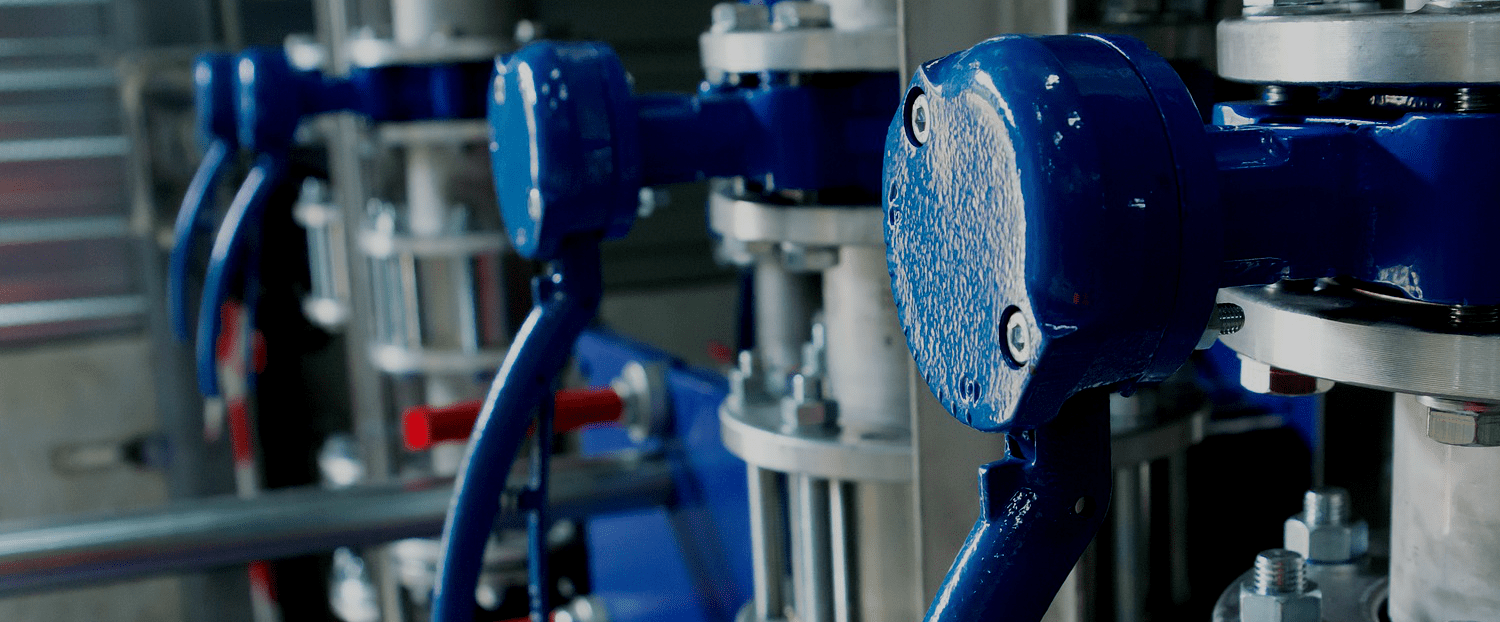

EJ Consulting’s team had an existing valve that they needed to change the size of. Testing a valve physically would have been a difficult process—pumping 200-1000 GPM and accurately measuring the pressure drop, flows, and forces is not practical.

The team knew that if they did not use computer-aided engineering (CAE), they would need to estimate the flow from similar valves, and not alter the design. With CFD simulations, however, they could include marketing material that contained enough technical data for engineers to make a valve selection. The engineers anticipated the simulated valve would perform better than the currently advertised one.

With the simulations done on SimScale, we characterized the valve (original goal), and gained much greater insight into the interaction between the valve and the fluid at each valve position. This will help us provide a better analysis in the future. SimScale has proved to be for the firm a flexible and scalable tool, which was critical for a HUBZone firm like ours.

Engineering Team

EJ Consulting

The workflow for this project could be described as follows:

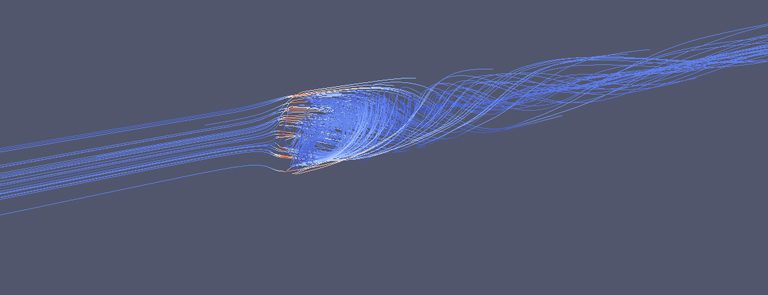

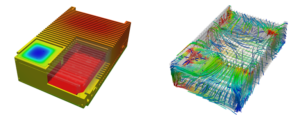

The focus of the simulation was very broad, as CFD incompressible fluid and FEA static analysis were performed.

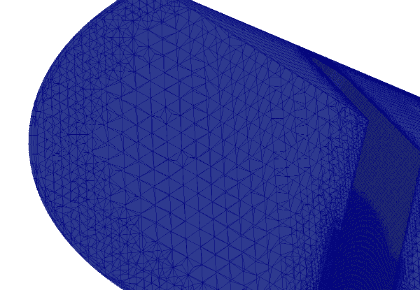

The engineers modeled 7 different valve sizes at 5 different positions (35 meshes). This required approximately 105 simulation runs for various velocities. A CAD software to create the flow volume was used—6 pipe diameters upstream and 10 pipe diameters downstream, where pressure taps would be installed in a physical test environment.

The biggest challenge was to set Hex-dominant refinements for each trouble area of the mesh. Using Hex-dominant refinements proved accurate, but costly results when using it for individual problem areas. As an alternative, the EJ Consulting team compared the results to the tetrahedral mesh with layers and confirmed that the results were applicable and useful. Having both processes allowed them to confidently navigate between an economical simulation process and the most accurate method.

The team ran 5 simulations simultaneously. Most of the simulations were running on a single core and took about an hour to complete. The time was not a concern since the analyses were not consuming the company’s machine power.

For the hex meshes, 8 cores were used to provide enough memory and computational power. The calculation would take 2 hours due to the increased complexity of the system. Each simulation helped to tweak the velocity selections for the next run. The simualtion results helped the team gain a much greater insight into the interaction between the valve and the fluid at each valve position.

The engineers modeled 7 different valve sizes at 5 different positions (35 meshes) with the SimScale cloud-based platform. This required approximately 105 simulation runs for various velocities.

Sign up for SimScale

and start simulating now