Dolav is a leading global provider of superior handling and storage solutions. Renowned for excellence and innovation since 1976, Dolav specializes in producing large-volume pallet boxes for agriculture, logistics, food, and waste/recycling markets. Dolav manufactures products that eliminate the use of one-trip returnable packaging and all products can be fully recycled at the end of their life. Box pallets experience continuous handling during packing, loading, transport, and off-loading and must be durable, long-life, and cost-effective. In some markets the lifetime durability requirement after repeated use is 20 years which is why structural simulation at all stages of the product development process is critical.

The engineering team at Dolav uses FEA static and dynamic simulations on all product designs. Most simulation studies start off as requests for load testing on new products designs. Since customization is a key part of the service offering from Dolav, there is always a pipeline of new designs that need developing. The requests to perform analyses during product design are to assist in making design decisions before moving to physical testing and production stages. Compliance testing is also increasingly relying on simulation to quickly evaluate loads to meet safety and transport standards across multiple global jurisdictions.

The starting point is always static loading analyses which are straightforward. The design team simulates the resistance of the box pallet to maximum loading over time, loading the box pallet on different types of shelving, and stacking box pallets on top of each other. Dynamic analysis is used to assess any structural weak points in the box pallet when it is dropped from a certain height. These types of impact tests are compliance- and safety-driven and are an increasing part of the simulation work at Dolav.

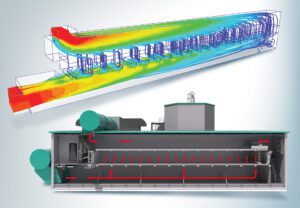

A recent project involved a customized tall box pallet for a special production run with structural reinforcements for the walls. The team wanted to check if the box pallet could withstand the required load in its given storage conditions. A static analysis simulation was used to evaluate a load on the inside base and a load on the box pallet walls. The goal was to see that the box pallet would not collapse under the load placed on it (the load was higher than the original definition but with storage conditions that could allow it).

The team also checked that the reinforcements in the walls were strong enough and the walls did not begin to deform up until a certain load point. In the end, the team found that it was correct to add an additional reinforcement as the analysis showed too much deformation in the box pallet walls. By using simulation to evaluate options quickly the team was able to add 50% loading capacity to the bin by quickly simulating various structural support additional to the walls. A redacted version of the proprietary design is shown in the simulation images below.

Working with analysis software like SimScale has saved us considerable time on conducting field experiments. In practice, the analyses are not supposed to replace field experiments, but they have significantly shortened the process since we can reduce the number of prototypes that are physically manufactured and tested. In situations where there are dilemmas between different types of design, the analysis can be very helpful in making critical decisions quickly.

Ofir Akiva

Mechanical Design Engineer at Dolav

Sign up for SimScale

and start simulating now