Established in 1946 in Joinville, Brazil, Busscar has 70 years of experience in bus development for the Brazilian and foreign market. After 5 years of closed activities, the brand was acquired by Carbuss in June 2017. With a timeless design and state of the art technology, Busscar is back bringing together with its products the most important asset of the company: the know-how of its previous collaborators.

Carbuss is well recognized for its expertise in structural development, with a focus on virtual and physical tests.

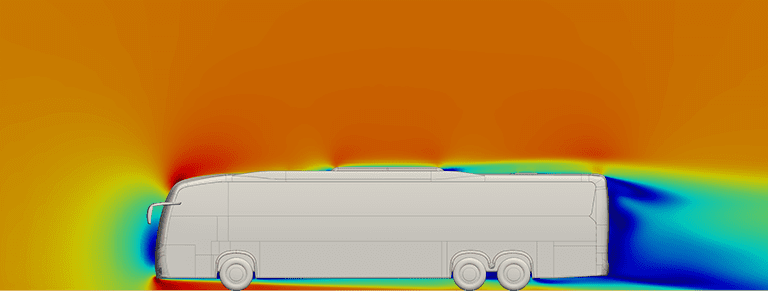

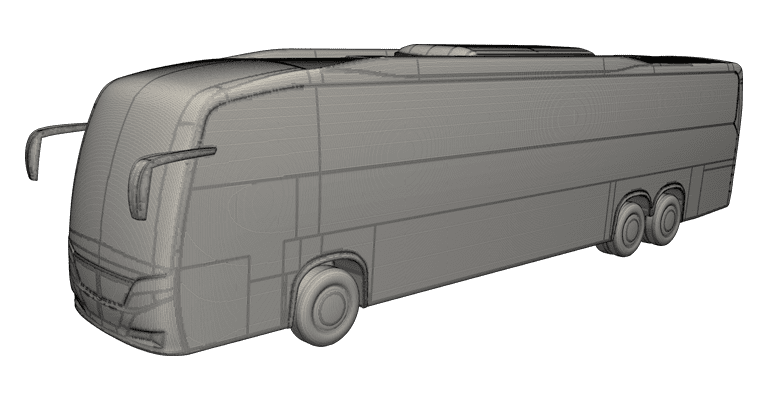

For their new project, VISSTA Bus 360, the company turned to computational fluid dynamics (CFD) simulation to study the new design and achieve the smallest drag possible. Their aim was to deliver to the market an optimized bus with lower fuel consumption and thus reduced operational costs.

For Carbuss’s core customer base in the transportation industry, fuel consumption is the factor with the strongest influence on overall costs, and is therefore a significant consideration in any new bus purchase. To tackle this issue, Carbuss set out to significantly reduce the drag of their new bus body, especially when compared to their previous model, the VB 360 Elegance.

As beginners in the usage of CFD, the support provided by our SimScale customer success engineer and other application engineers helped us significantly speed up our learning process with the platform and take value out of it.

Hugo Kuhn

Product Development Engineer at Carbuss

For the first step in the testing process, Carbuss produced three different CAD models, one each for their old and new designs and an extra design from one of their competitors. The geometries were then uploaded into the SimScale platform for meshing. In the cloud environment, a virtual wind tunnel was set up with the proper dimension, in order to capture the fluid development and to correctly calculate the drag forces and coefficients. The domain contained a moving floor and rotating wheels .In order to simulate the bus at 25 m/s (generally considered the safe speed on highways for buses) these wheels were rotated about their axis with an angular velocity that matched the tangential velocity of the floor.

The Hex Parametric mesher was then used to generate an 18 million cell mesh. To properly create the mesh, features such as inflated boundary layers, region refinements and feature refinements were used in a very quick process that took barely 10 minutes. The meshing operation for all three models was then completed in less than 90 minutes, using a total of 96 cores.Regarding the speed of the meshing process, Carbuss had this to say “This is one of the great benefits of SimScale: the capability to run unlimited operations in parallel without a reduction in computing power.”

Following the meshing process, the models were ready for simulation. Incompressible fluid flow simulations were performed, again using a total of 96 cores. Different boundary conditions were then applied, such as a 25m/s velocity inlet, a pressure outlet and moving walls for the floor and the angular velocity of each wheel axle. These simulations were succesfully converged and each simulation took around 10 hours to finish.

The CFD simulations performed in the cloud with SimScale gave Carbuss engineers, Hugo Kuhn and Fabio Luis Crema, valuable insights into the aerodynamic performance of each bus design version analyzed.

After carefully post-processing the data, Carbuss’s engineers were able to propose additional design changes for the final body. One of the primary improvements was the detailed design of the mirrors, which was partially changed after assessing the drag coefficient of the VB 360 Elegance model.

The improved design of the VISSTA Bus 360 reduced drag coefficient by 16% and drag force by 15%, compared to the previous VB 360 Elegance model. The drag force of the new model is even 5% lower than that of the best reference value found of the main competitor model.

“With SimScale, at Carbuss, we were able to assess the drag force and coefficients of our previous bus design and improve it during the early phase of our product development process,” said Hugo Kuhn, Product Development Engineer at Carbuss.

As the VISSTA Bus 360 gets closer to market release, the studies performed with SimScale have had a great impact in the development phase, not only reducing time spent in testing, but also making it possible for Carbuss to deliver a more efficient bus to its clients.

“The SimScale platform was essential to mature our product design! The return on investment is hard to measure at this point, but it will be seen when our customers note that they are acquiring an optimized vehicle with a reduced operational cost compared to our competitors,” said Hugo Kuhn, Product Development Engineer at Carbuss.

Sign up for SimScale

and start simulating now