Carbomech wanted to bring to the market a new air bearing spindle equipped with a DC motor which would be able to reach 180,000 rpm during operation. Finite element analysis (FEA) was used throughout the design phase to find the natural frequencies and modes of this design proposal and at the same time to dimension its geometry to guarantee that, when achieving high speeds, the deformation of the shaft’s shape wouldn’t generate issues with the air bearings.

Being a startup, Carbomech could not afford to test all the design proposals they had. Consequently, adding numerical simulations early in the design phase of this new spindle was the right solution to save time and money while knowing that the results were accurate.

A big part of the experience with SimScale is the support. Even if SimScale gets better and better, there are so many choices. You must have somebody helping you to choose!

Fabrizio Pauri

CEO and Chief Engineer, Carbomech

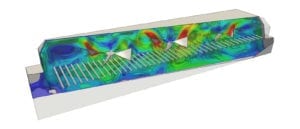

The project involved running a modal analysis to find the right compromise between stiffness and mass. The aim was to operate the shaft at speeds safely distant from the natural frequencies where spindle destruction is certain.

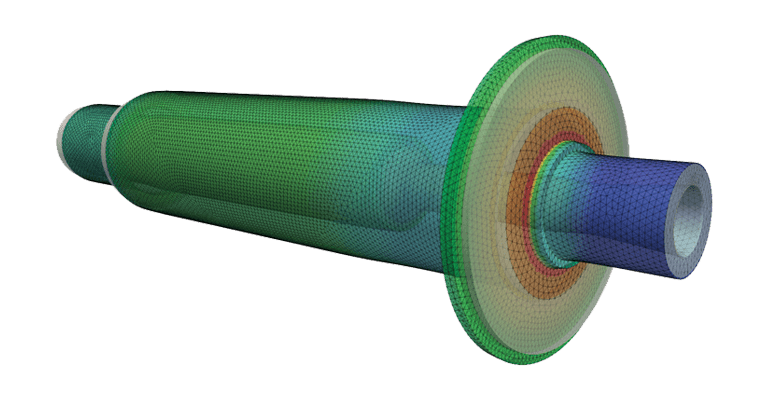

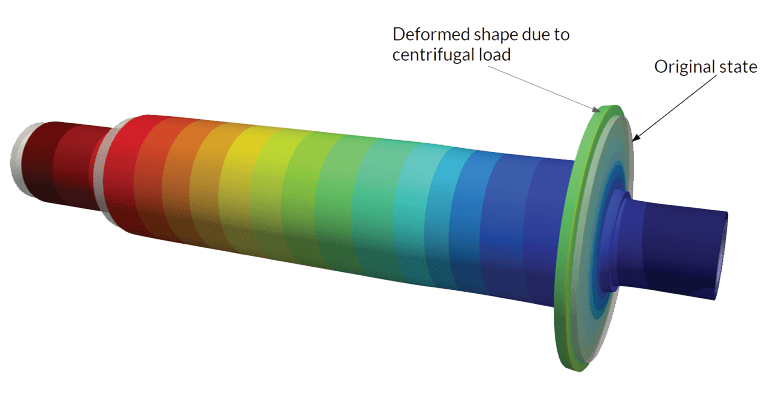

After achieving a desired configuration based on the natural modes and frequencies, Carbomech’s CEO and Chief Engineer Fabrizio Pauri also ran a centrifugal load analysis of the shaft to check stresses and deformation on the spindle at 180,000 rpm.

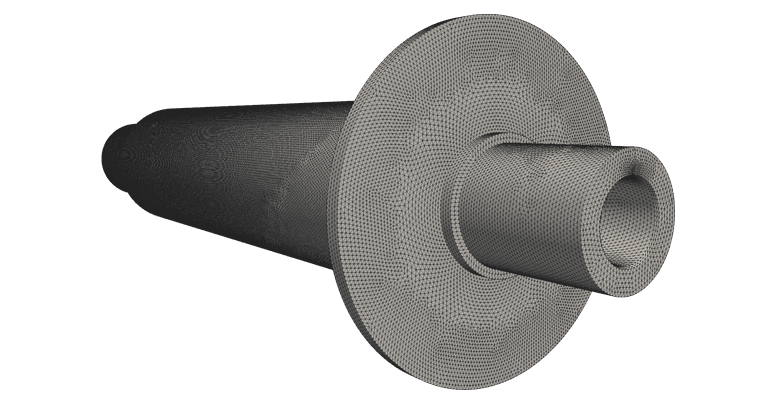

The spindles measure around 0.13m in length and have different cross sections with the outer diameter varying from 6mm to 20mm. In order to properly assess this kind of geometries, a second order element mesh was created with around 500 thousand elements.

A modal analysis was then performed for two different spindle designs as part of the first stage in the development phase. The main goal was to assess the natural frequencies and modes of the spindles in order to check if changes in terms of mass distribution would be needed to guarantee a good stiffness.

Finding the natural frequencies helped to define the speed range where the shaft can run safely.

Operating the spindle too near to a natural frequency would deform the shaft in such a way that it will crash against the surfaces of the air bearings.

Following the design phase, a centrifugal load analysis was then performed by using the same second order element mesh which was previously created. Boundary conditions were then assigned to mimic the air bearing case and a centrifugal load of 180,000 rpm was applied to the spindle.

With this kind of analysis, the main goal was to assess the displacement around the ‘disk’ which stays inside the bearing’s case and has limited space to expand due to a high rotational speed. The stresses were also assessed with the online post-processor tool available inside SimScale.

Since the gap between parts in relative movement is in the range of few micrometers where air bearings are used, it is crucial to correctly simulate all the deformations of the shaft.

With the use of FEA with the SimScale cloud-based platform, the Carbomech team could then calculate the displacement due to the high speed of the spindle on this region of interest, at 180,000 rotations per minute.

“Support is super good! The few times I had something wrong or hadn’t understood something, I would simply email the Customer Success Engineer and minutes later the solution was there. I can only say that the level of support is very good!”

The FEA simulations performed in the cloud with SimScale gave Carbomech’s team valuable insights into the mechanical performance of their high-speed spindle.

The team had to build 50% less prototypes for physical testing than usual by adding SimScale to the design phase. The price of each spindle is 3-4 times more than a SimScale subscription, which makes the return on investment (ROI) very high.

The current CM180 spindle has been redesigned by using the results from simulations made with SimScale. An improved design has already been validated by further simulations with the platform and is currently in development.

“Well, I have a dedicated Customer Success Engineer watching over me, helping me to actually squeeze out the value from the service. What more can I ask for?”

Sign up for SimScale

and start simulating now