Bold Valuable Technology offers design and manufacturing services to the motorsport and aerospace industries. They specialize in battery pack integration and structural composite & mechanical components. Additionally, they provide added value from the design stage, and take care of manufacturing to supply finished products to their customers. The design work is carried out in Girona, Spain. For manufacturing and testing, Bold uses a network of top suppliers for raw materials, machining, composite parts, and testing, mainly from the UK.

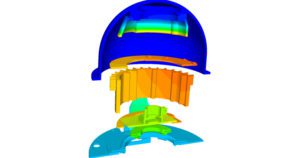

In this noteworthy project, Bold set out to develop a battery concept for a high-end motorsport electric series. The scope of work consisted of the development of the battery, and based on a pre-selected cell, this product needed to perform mechanical packaging and integrate a cooling system within the design.

The nature of this project, specifically in the cooling system design, required thermal simulation. Before incorporating computational fluid dynamics (CFD) tools, Bold’s approach in the past was to use analytical calculations which required a high degree of simplification, and physical testing. However, they found that this process was far from ideal, especially when dealing with supplies on a global scale. And so, Bold Valuable Technology decided to give cloud-based CFD a try through SimScale.

The difficulties in accurately predicting the thermal behavior and pumping losses in the cooling system were only possible to tackle using CFD tools. The main advantage we find in simulation is the speed at which we can try different ideas and design parameters. The post-processing tools allow us to understand the behavior of the system so our engineers can come up with improvements or discover issues before building prototypes.

Bernat Carreras

Director at Bold Valuable Technology

After comparing different CFD software, SimScale was chosen for their project. The cloud-based software provided the Bold team with an easy-to-learn interface that allowed them to set up the model in a simple way, all from a web browser.

They found that SimScale drastically reduced costs, and the cloud-based operating system made things cheaper in terms of computing power, especially when working with consultants remotely. Furthermore, SimScale was able to offer an experienced support staff that explained how to use several tools, which helped the team troubleshoot if and when they needed to. The final benefit that Bold noted was SimScale’s inclusive core hour plan, which saved Bold from having to worry about liaising with a third party.

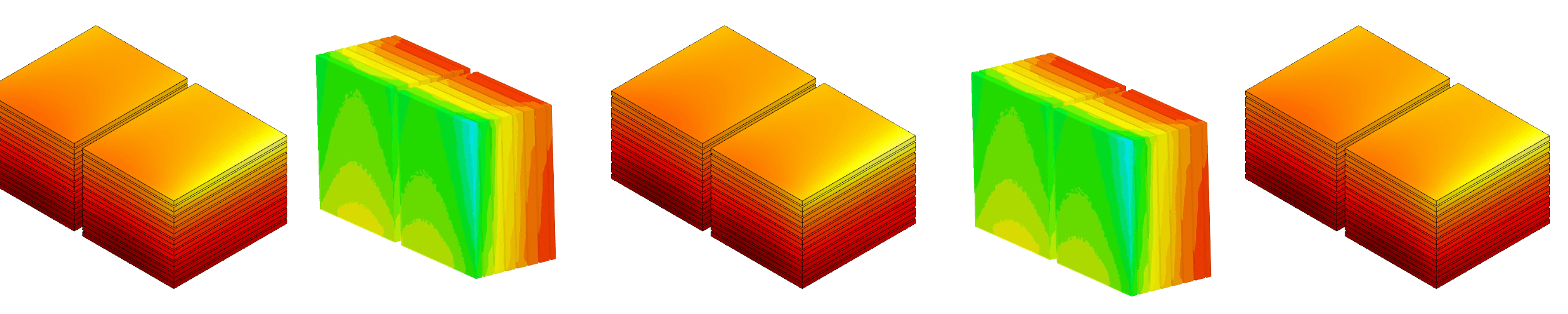

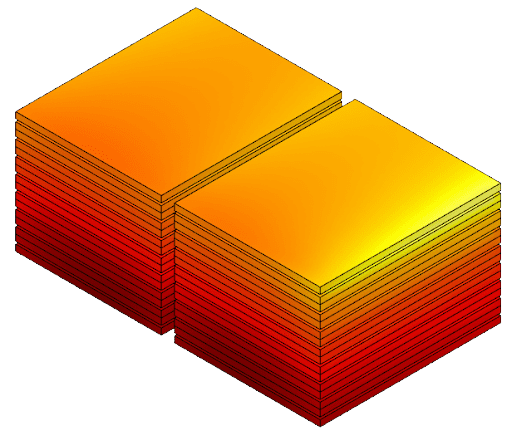

For the cooling system design, it was required to perform a conjugate heat transfer simulation. Before that, a solid heat transfer and an incompressible fluid analysis were performed as a starting point. The team at Bold made a comparison amongst many different cooling concepts through solid heat transfer analysis. This method allowed them to make their first selection. Amongst the last three candidate concepts, an incompressible fluid analysis was performed in order to estimate the pressure drop for each design option.

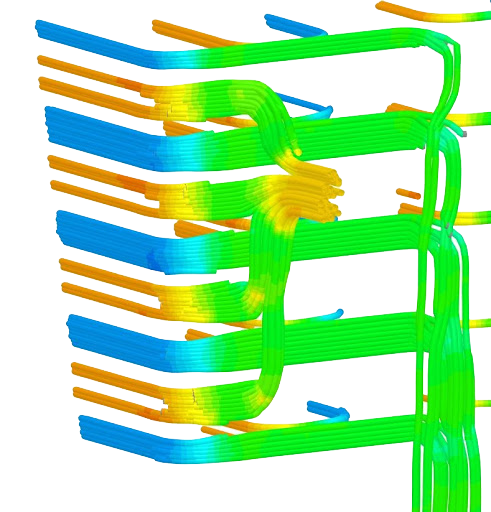

Finally, the team set up several models with a conjugate heat transfer simulation, including different boundary conditions like heat generation in the cells or air convection heat flux in the cells and the cooler. Different flow rates were simulated, and thermal gradients in the fluid and cells, as well as pressure drop between coolers, were compared.

One of the biggest challenges in the process was to create a mesh for our models, a vital step in all CFD simulations and crucial for obtaining valid results. Some solid components were only 0,3 mm thick and there were a number of thin fluid channels. With the help of SimScale's technical support we were able to solve these problems.

Bernat Carreras

Director at Bold Valuable Technology

For the whole project, Bold ran more than 100 simulations, with an average runtime of 30 core hours. From these simulations, Bold obtained a large range of results, to then be used as parameters to evaluate each cooling system. Some of these results were: max and min cell temperatures, internal cell gradients using cutting planes, coolant flow streamlines, pressure drop between inlet and outlet as well as coolant temperature gradient between inlet and outlet. The outlet fluid temperature was used as a monitor for evaluating the simulation’s convergence.

The team concurred that their experience with SimScale was great, and all qualms were quickly solved with the help of the support team. SimScale’s intuitive interface made setting up the model easier than other CFD software. The possibility of choosing the number of cores for each simulation and working in the cloud gave the team a lot of flexibility.

Finally, Bold was able to use the plots directly from SimScale for reporting. They were also able to export the output file to analyze it further in third-party software, in order to calculate even more parameters. SimScale brought Bold a cost-effective solution by reducing the number of experimental tests needed for the project. Furthermore, it removed limitations such as the number of cores available, and enabled the possibility of having different users working remotely at any moment.

Bold Valuable Technology plans to expand on the use of simulation with more detailed models to better predict the thermal behavior of their cooling systems. At the same time, they plan on keeping a more flexible working strategy, which SimScale also supports.

“Bold has been able to provide valuable solutions to our high-end motorsport customer using conjugate heat transfer simulations, that would have not been possible with other software due to cost and computational resources required. The SimScale team has been very helpful every step of the way.”

Sign up for SimScale

and start simulating now