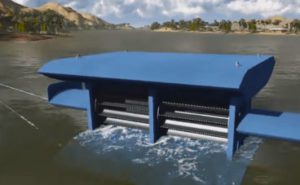

Axolot works with water flow processes, therefore turbulence and flow speed are key factors they need to understand in order to execute an efficient water treatment system. When Axolot Solutions came to SimScale, they were in an extensive period of product development, and wanted to design system components and test processes digitally rather than buy components and conduct physical trials.

Axolot Solutions decided to optimize their designs and determine design flaws through CAE, and specifically CFD, rather than through physical testing due to time and money savings. With earlier experience from other CAE platforms, application engineer Christian Ademius knew what could potentially be achieved through online simulation.

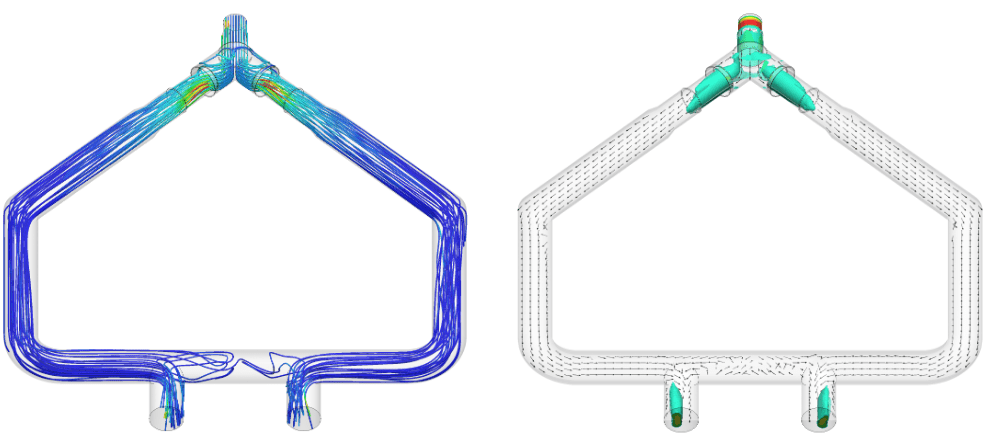

I expected to be able to see good visual results such as in the flow and turbulence simulation within the pipes. We could then estimate new designs that would meet the continuous expected results. We looked at several CAE programs but felt that SimScale offered the most value for the price and the communication with the SimScale team has been excellent.

Christian Ademius

Application Engineer

After looking at several other CAE programs, Axolot decided that SimScale offered the most value for the price, and began working with SimScale’s application engineers to simulate their designs.

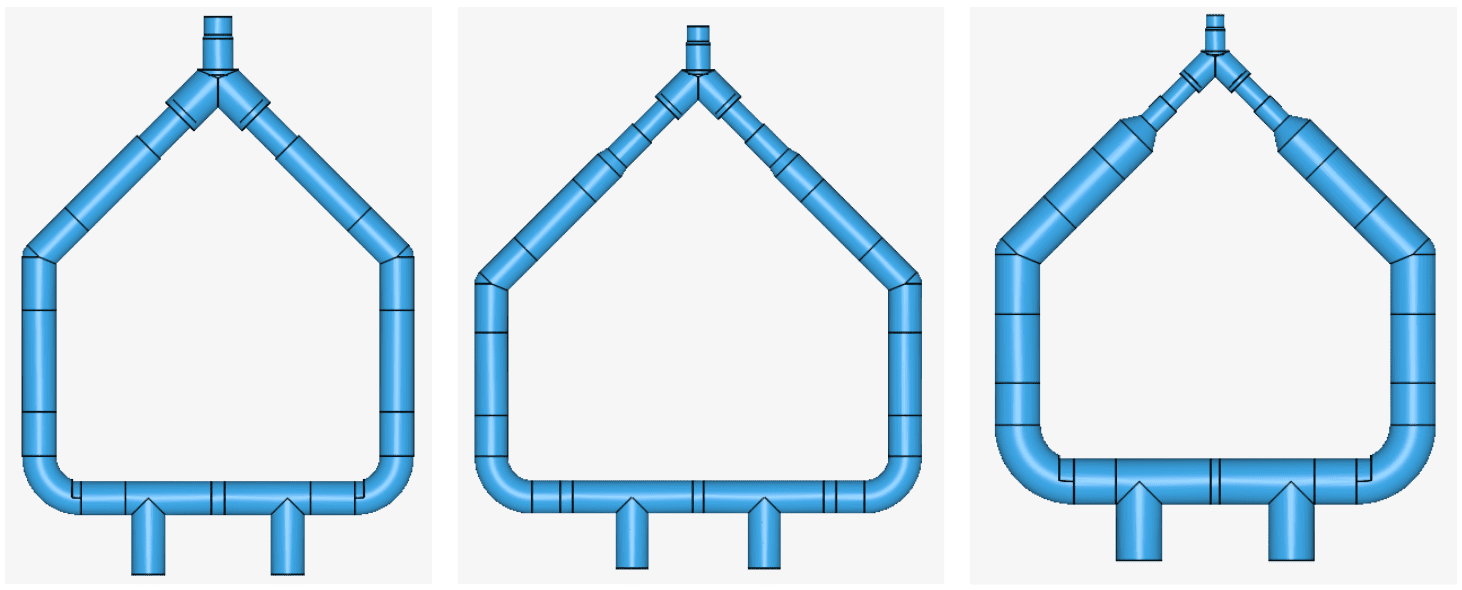

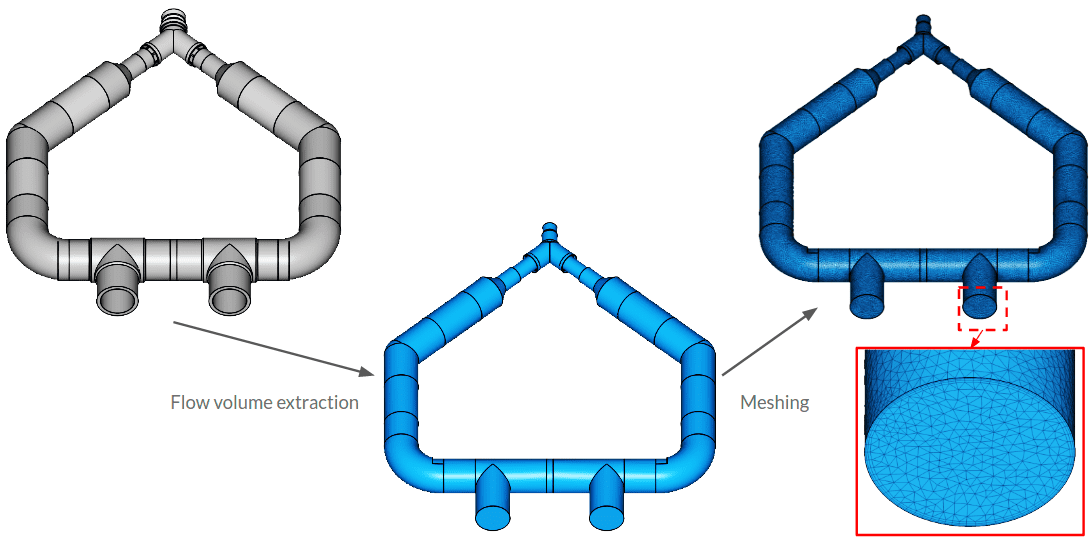

For their specific design, Axolot sought to determine how the volumetric flow was distributed from a main pipe to two outlets. Their design target was to achieve a specific velocity range at the outlet by keeping the turbulent kinetic energy, space requirements, as well as the complexity of the design low as possible. They initially had support to set up the inner volume extraction, but were then able to complete their evaluations autonomously. This involved detecting the mean volumetric flows using default automatic meshing and default inflate boundary layers.

Axolot Solutions found that the simulation ran quickly and gave realistic values and results. In total, they ran about 6 simulations, at an average of 39 minutes using 5.3 core hours. Between the initial and final design, they achieved 89.7% reduction in maximum turbulent kinetic energy.

Since using SimScale, Axolot has been able to reduce the number of physical prototypes as well as shorten their development time. They will continue to use SimScale for further development of new setups for targeting new problems and design ideas.

Christian Ademius

Application Engineer

Sign up for SimScale

and start simulating now