Aquabio is a pioneering company born with a passion for innovation combined with a strong ethos for environmental sustainability. For over 20 years they have provided some of the world’s most advanced systems for the treatment and reuse of industrial wastewater at their customer facilities. Aquabio delivers solutions from concept development through to complete installation whilst saving valuable energy, recovering resources, and significantly reducing costs. Aquabio is part of the Freudenberg Filtration Technologies group.

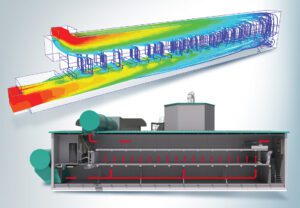

Aquabio is a specialist company dedicated to designing and building anaerobic industrial water treatment plants. With a focus on effluent from various industries like dairies, farms, distilleries, and manufacturing plants, they offer comprehensive solutions including design, installation, management, and calculation of treatment systems. They don’t operate plants but are involved in project management, commissioning, and testing. Based in Worcestershire, UK, with about 35 employees, they have completed 20-30 projects across the country. Key personnel like Alex Meredith contribute to plant design, tendering, and pricing, ensuring thorough verification before construction. As SimScale users, their focus includes bio-reactor tanks and mixing tanks, particularly in modeling incompressible fluids and branching out to thermal analysis. They handle large plants with typical flows of 200 m³/h, maintaining high standards of compliance.

Previously we were outsourcing CFD simulations to consulting firms which was taking a lot of time and cost from our projects. With SimScale we’ve brought simulation in-house and have been able to do this with the excellent support from SimScale. I can now use engineering simulation at a much earlier stage of the project including bidding for tenders.

Alex Meredith

Engineer at Aquabio

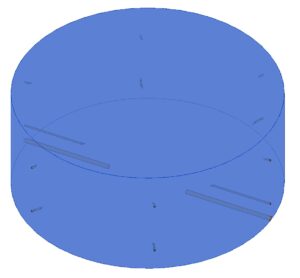

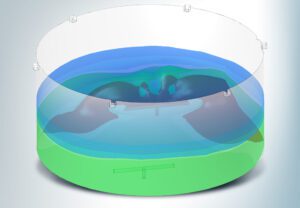

Alex and his team used SimScale to design the mixing tanks of an industrial anaerobic reactor for one of the largest dairy processing units in the UK. The mixing efficiency has a large impact on overall plant performance and hence efficiency. The tank in question was an as-built design for the 27.3 m diameter Anaerobic Reactor Tank. The objectives of the CFD study were to confirm that the contents of the reactor tank would be completely mixed, for both low capacity (9 m) and full capacity (11.5 m) fluid levels, specifically:

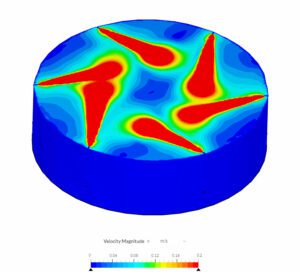

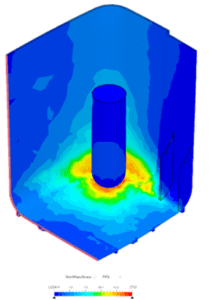

The low-capacity anaerobic reactor tank was modeled as a cylinder of 27.3 m in diameter and a height of 9 m. The full-capacity anaerobic reactor tank was modeled as a cylinder of 27.3 m in diameter and a height of 11.5 m. Two banks of six angled mixing nozzles with 50 mm diameter outlets were evenly spaced around the tank. The first bank is located 2.3 m from the base of the tank, and the second bank is 7.9 m from the base of the tank. Two of the lower bank nozzles protruded 6.2 m into the tank to aid low-level mixing towards the center of the tank.

The total volumetric flow rate of fluid coming out of the two banks of 6 mixing nozzles was 1,600 m3/hour, which equates to 0.037037 m3/sec per nozzle. The flow into each of the two suction pipes was 800 m3/hour, or 0.22222 m3/sec per pipe.

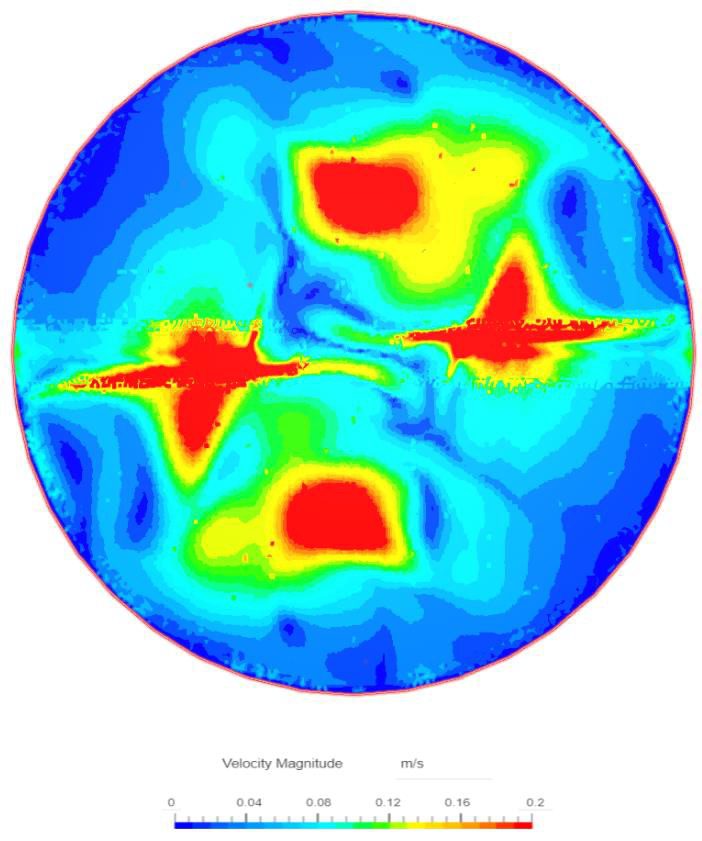

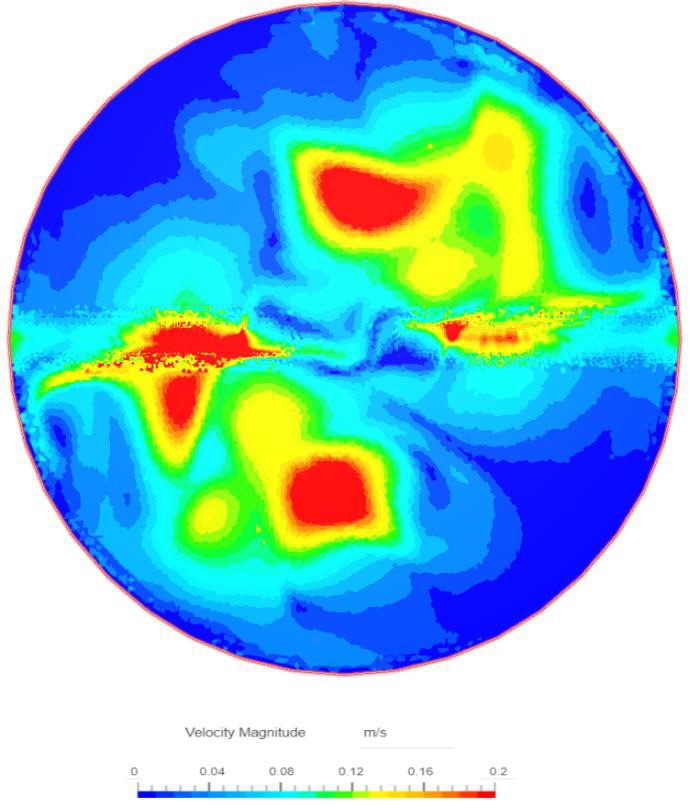

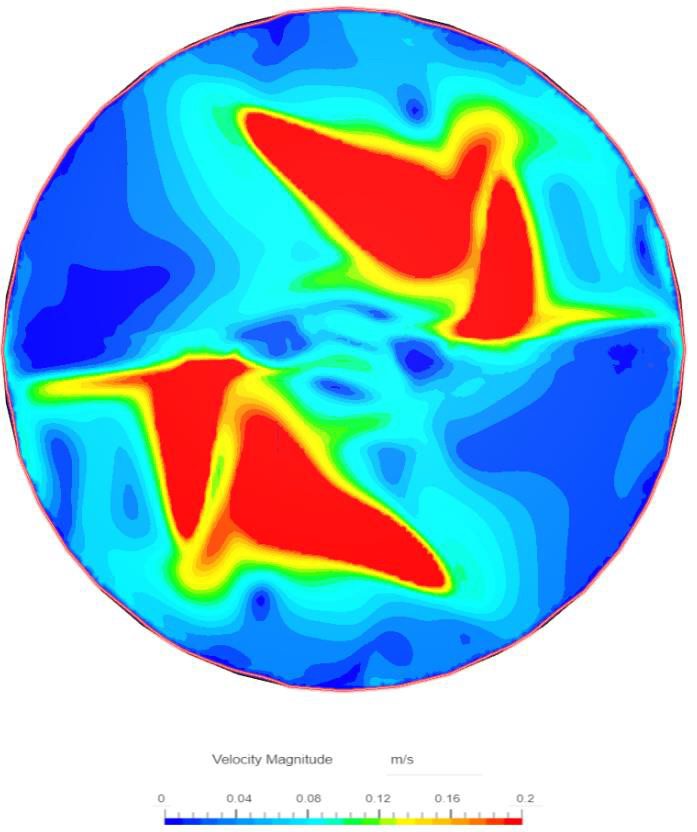

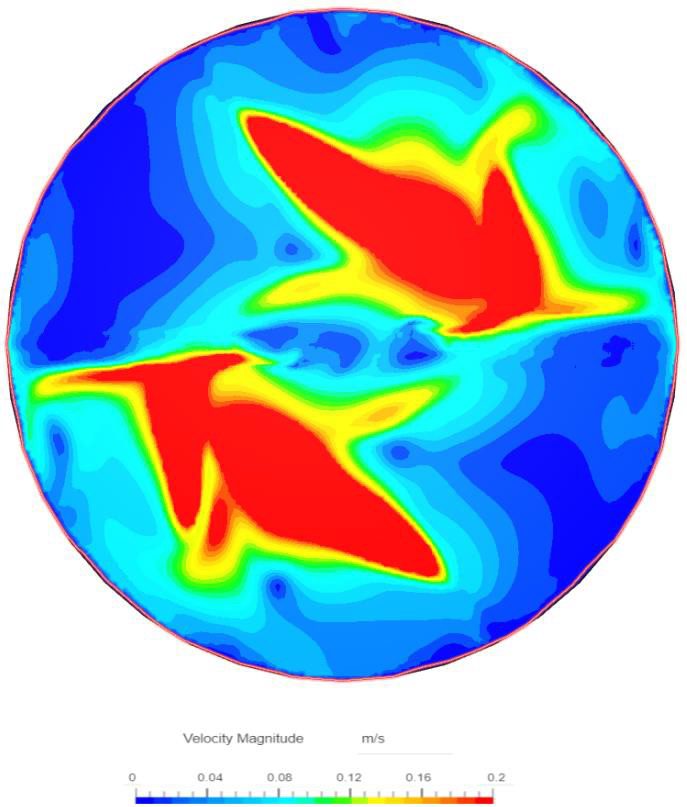

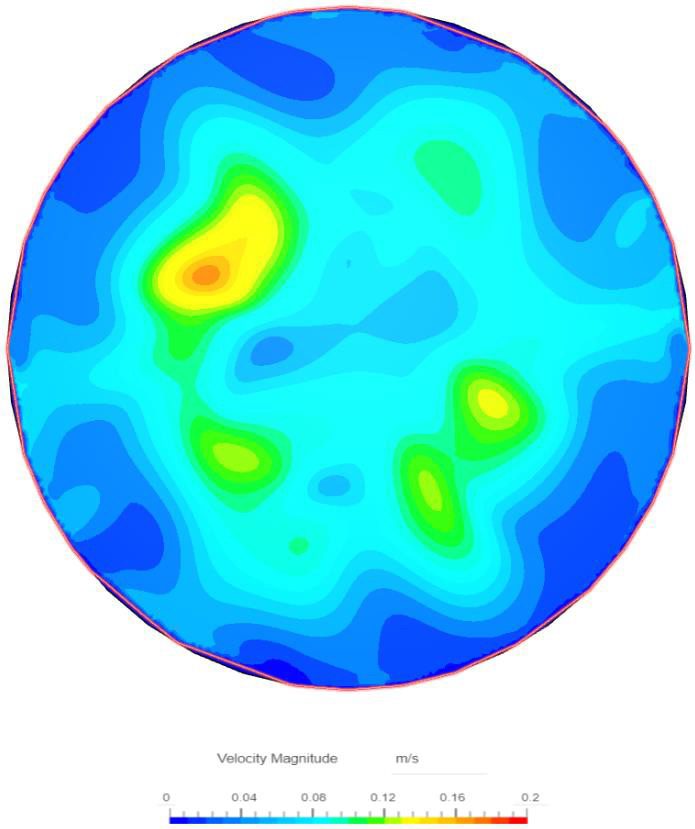

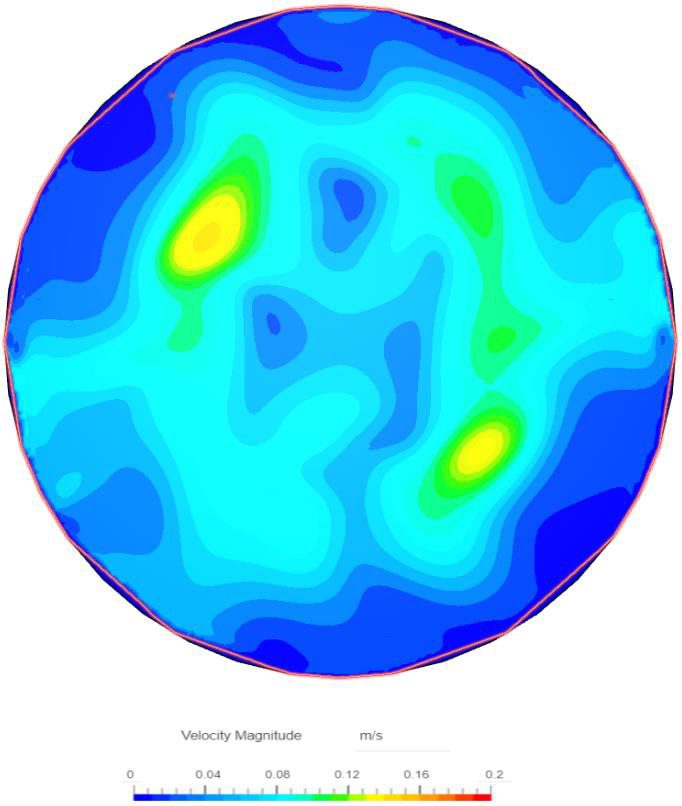

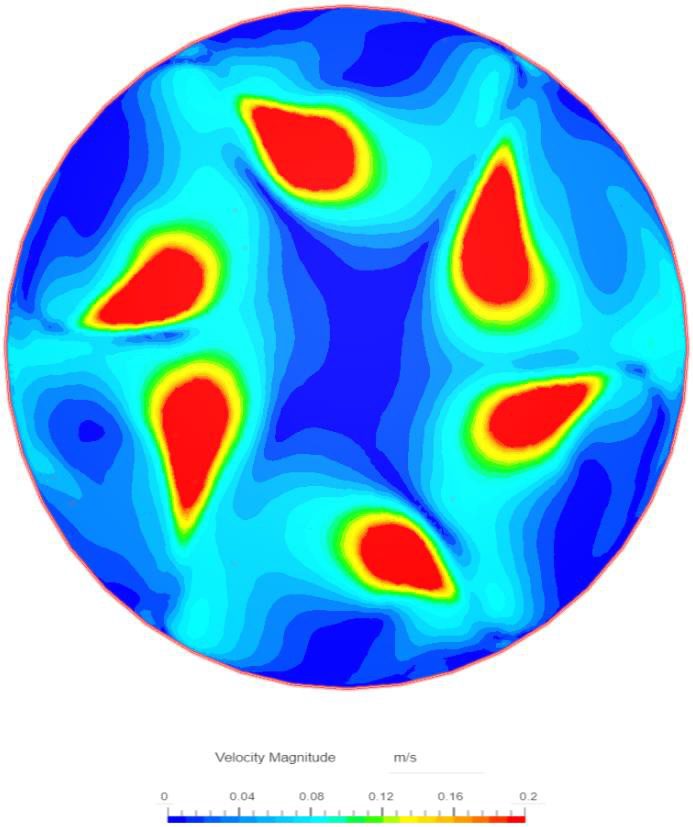

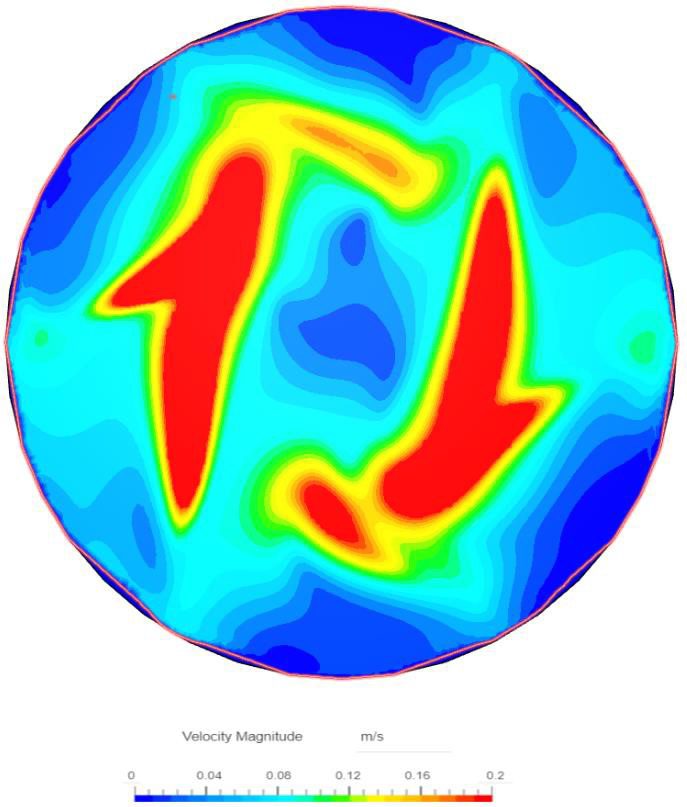

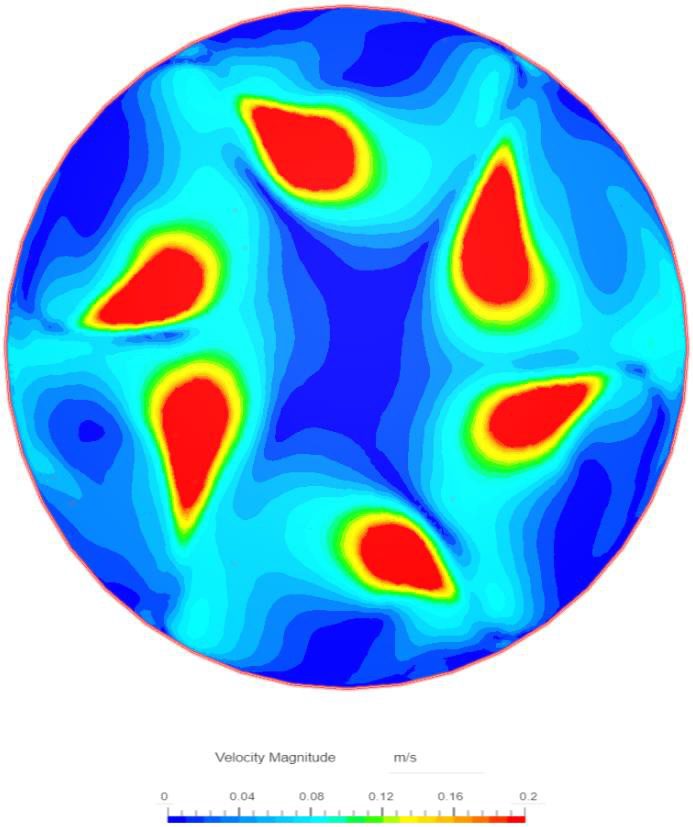

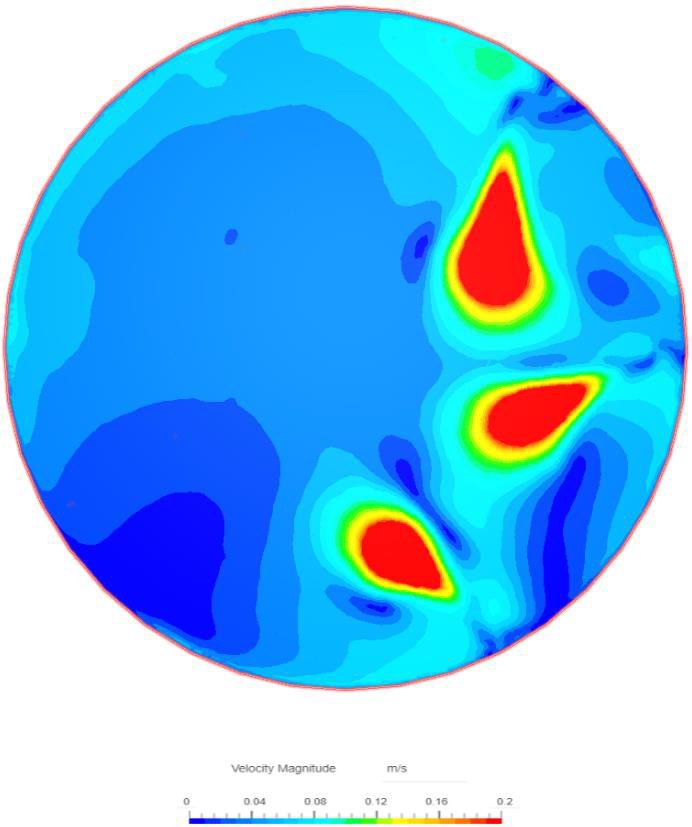

The following images show a comparison of the two tank sizes illustrating mixing efficacy at various tank heights. Large amounts of red, orange, and yellow indicate that the fluid is mixing at a good rate. Large amounts of green and light blue indicate that the fluid is mixing slowly. The dark blue areas represent stagnant fluid. Overall mixing quality is assessed by analyzing screenshots taken of slices cut through the tank in SimScale (see images). The left images are the results of the simulation of the tank at low capacity (9 m water level). The right images are the results of the simulation of the tank at full capacity (11.5 m water level).

As well as comparing the mixing of the two tank sizes, the client also wanted to know how mixing efficacy would be impacted with just one mixing pump operating. The results from these simulations show that the anaerobic reactor tank still mixes sufficiently with only a single pump, and therefore 6 mixing nozzles, in operation. The screenshots of slices taken at different heights of the tank show good mixing levels throughout the whole of the tank when operating at low capacity.

For the low capacity (9 m) simulation, the tank was well mixed at all depths. Only a few small areas of dark blue can be seen indicating fluid velocity. For the full capacity (11.5 m) simulation, the tank was well mixed at most depths. However, at the top levels of the tank between z = 10 m and z = 11.5 m, the fluid is mixing at a reduced rate as expected. The model did not account for mixing induced by air bubbles that are entrained into the system from the aeration nozzles. This means that real-world mixing will be better than the SimScale model, particularly high up in the tank. Reassuringly, the results from simulations align with design experience from past projects, estimating that the fluid in the tank is sufficiently mixed.

One of the key benefits of having SimScale in-house is risk mitigation on our projects. In the past, we built and installed plants, and during the operation phase, we had issues of reactor tank mixing efficacy which lowered the overall efficiency and hence ROI of the plant. Mitigation was a huge cost that could take weeks of work to rectify. We can now confidently test various designs and operating modes at the simulation stage before we build anything.

Alex Meredith

Engineer at Aquabio

Sign up for SimScale

and start simulating now