Anderson CNC manufactures computer numerically controlled (CNC) machines under the brand Stryker Machines since 2001. The business started with the goal of building CNC machines that could help automate the metal plate cutting process. One of the machines it manufactures is a CNC plasma cutting table.

The company’s first machines used water as a filter for the smoke and gases generated during the cutting process. The water was placed beneath the metal plate, and as the smoke exited it, it was captured in the water.

It soon became clear that the water filtration system created other problems: small parts that were cut out of the metal plate would fall into the water tank, making it hard to find them. The engineering team needed to build a new CNC plasma table that would remove the smoke using an extractor and a system of compartments beneath the metal plate. The engineers wanted to analyze the propagation of smoke through different CAD models in order to optimize the location of the smoke outlets.

Not having the luxury of time and money to build and test the different designs, and considering that nobody on the team had sufficient experience with computational fluid dynamics (CFD), the company began looking at different simulation software and came across SimScale. Being cloud-based, the platform was very accessible for virtually testing the designs and all the available tutorials together with personalized support helped Anderson CNC overcome the know-how barrier.

We saw that there was quite a bit of information in the forum and tutorials that could help reduce the learning curve. As we inquired more into SimScale, we found out about their onboarding option which would provide us with expert assistance in CFD simulations.

Anderson CNC

Team of Engineers

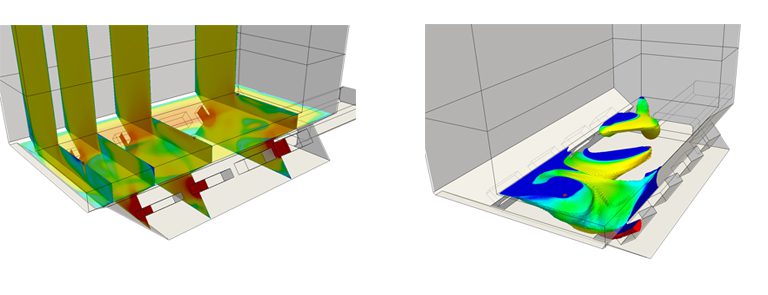

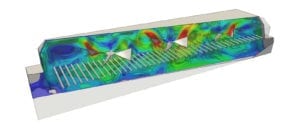

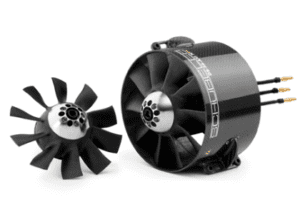

With the help of SimScale’s engineers, the customer set up different CFD simulations to test the compartments. The first step of the numerical analysis required to define the air domain from the CAD. With the volume extract, a general mesh was prepared. By specifying refinements at multiple smoke inlet areas, the same mesh was used for the analysis of several operating conditions. The modeling of smoke was done by using the passive-scalar solver. Steady-state simulations were used to investigate smoke patterns during the operation of the CNC table. Several smoke inlet locations were studied, together with different air suction conditions.

Thanks to the possibility of running multiple simulations at the same time, the engineers at Anderson CNC could investigate all the configurations at once and obtain all the results after 2 hours of calculation.

The simulation carried out with SimScale helped notice inefficiencies in the location of the smoke outlets, improve the channeling of the smoke to these outlets, and see turbulence generated in the ducting. It also contributed to defining the specifications of the extractor needed to remove the smoke.

Within two months after the simulations were performed, the engineers at Anderson CNC were able to finish the design and build the machine. Just as the simulations showed, the design efficiently removed the smoke. In the near future, the company will be incorporating CAE in further developing a system to separate the extracted smoke from the air and returning it to the environment.

The simulation carried out with SimScale helped notice inefficiencies in the location of the smoke outlets, improve the channeling of the smoke to these outlets, and see turbulence generated in the ducting.

Sign up for SimScale

and start simulating now