Adrian Smith + Gordon Gill Architecture (AS+GG) is dedicated to the design of high-performance, sustainable architecture on an international scale. The firm approaches each project with an understanding that architecture has the power to influence and aid society, advance modern technology, sustain the environment, and inspire those around us to improve our world. AS+GG’s practice includes designers with extensive experience in multiple disciplines, including architecture, interior design, urban planning, and sustainable design. The firm was founded in 2006 by partners Adrian Smith, Gordon Gill, and Robert Forest and today there are over 80 employees in offices in Chicago and Beijing.

AS+GG’s approach to integrated design emphasizes a relationship with the natural and surrounding environment, which takes into consideration factors such as building orientation, generation of wind power, and solar orientation. Among the firm’s projects are high-performance designs for high-rise buildings, where the building form can drastically shape the overall project sustainability. To reach optimal performance, AS+GG needs the ability to test designs as early in the design process as possible, even during the “competition” phase when early validation allows for multiple iterations and exploration of new design directions discovered through testing.

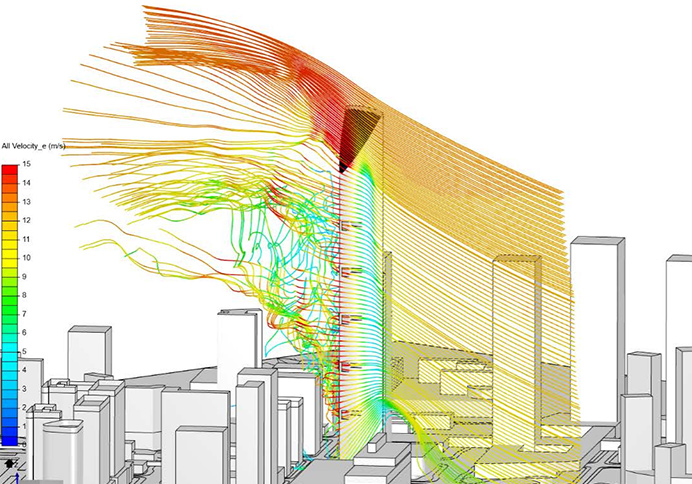

Transient vertical velocity contour through the building notches.

The timelines during the competition phase can be tight, often as short as one month, to design and optimize proposals. This timeline made working with external simulation consultants difficult, as turnaround times often required several weeks, leaving no room for design iterations. At the same time, the team found that working directly with simulation tools often required a steep learning curve or could yield questionable calculations, especially given the team’s limited expertise with computational fluid dynamics (CFD) and its application to forces like wind. AS+GG needed to combine speed, accuracy, and ease of use.

The lattice Boltzmann method (LBM) solver integrated into SimScale was the ideal solution for this. Developed by Numeric Systems GmbH, Pacefish® is a revolutionary implementation of LBM tailored to the massively-parallel architecture of GPUs. Its ability to run on multiple GPUs in parallel enables turnaround times that are 20-30 times shorter than with traditional methods.

By simulating designs with SimScale, AS+GG shortened design cycles, going from initial sketch to simulation results in less than a few hours. Additionally, the team at AS+GG gained more confidence in their simulation results, thanks to both the user-friendly platform as well as the expertise of SimScale’s staff, who offered best practices, case studies, articles, and other resources throughout the onboarding process. This allowed AS+GG to submit designs that would prove to have a high level of accuracy. Wind tunnel testing would also be used during later phases to support engineering efforts.

As AS+GG increasingly integrated SimScale into its design process, the team found that the cloud based software was constantly being improved, with new features being added within the platform without the need to redistribute or update any software. Specifically, the team at AS+GG recently began using the software’s new collaborative features, allowing them to share, view, and edit projects across team members in one common platform.

When we began using SimScale, we were able to shorten our CFD simulation feedback loop, which in turn allowed us to iterate and evaluate many design options at the earliest design phases of our projects. This proved to be particularly innovative because design changes during this time have the potential for the biggest impact on performance. The more our design team can test and make decisions based on these simulations directly translates to more confidence in meeting the project's performance goals as well as desired design outcomes.

Anthony Viola AIA

Architect, Adrian Smith + Gordon Gill Architecture

The team at AS+GG leveraged SimScale during a design competition of a supertall building in Shenzhen, China. In supertall buildings, the forces and acceleration experienced by the structure are heavily influenced by the form of the building. Therefore, it is critical that the form of the building is developed with aerodynamics (wind engineering) in mind.

Within SimScale, the team set up the initial site conditions and evaluated the dominant prevailing wind directions. The team then performed simulations on multiple design schemes to quickly evaluate the overall wind force experienced by the structure. This process allowed for an accurate relative comparison of the various iterations which led to further shaping and refinement models. Optimizing the building’s form at this stage could potentially minimize the amount of structural material and in turn the associated embodied carbon needed for construction.

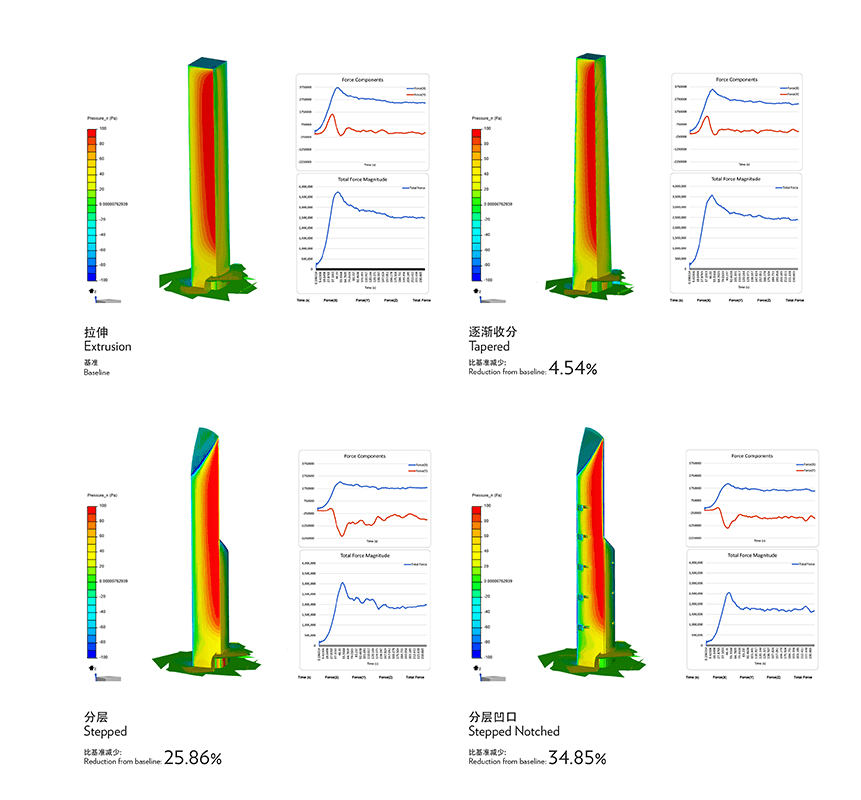

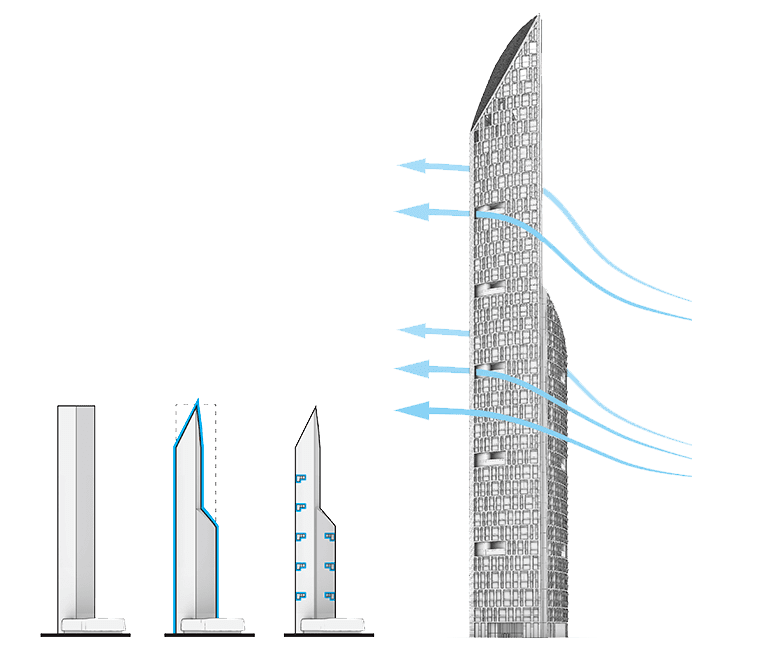

The team’s preliminary analysis indicated that, for this particular site, reducing the mass of the top of the building by stepping back the form was more effective at mitigating the wind loads than if they were to taper the building, a fact that was revealed through the design iteration and simulation process. Using a baseline rectangular extrusion, the various tapered versions produced an approximate reduction of 5% of the total force magnitude whereas a stepped version reduced the total force magnitude by 26%. A further reduction was made at a detailed level by utilizing wind relief slots that mitigate forces developed due to vortex shedding.

The analysis quantified the relative benefit of these slots to reduce the overall wind forces but also helped position vertical axis wind turbines within the slots to maximize the renewable power production of the proposal. The combination of these form optimizations and detail elements gave the building its distinct and iconic form and reduced the relative wind forces by approximately 35% from the baseline.

The team at AS+GG continues to utilize CFD analysis technology to evaluate the design performance of projects and iterate within the design process. SimScale has allowed for the confident development and evaluation of strategies as a comparative design analysis, and is used in conjunction with AS+GG’s structural and wind engineering teams to augment the quantitative analysis that they perform in greater detail. This iterative analysis and design process utilizing SimScale brings a level of speed, accuracy, and detail that will continue to help AS+GG achieve high-performance designs in which “form follows performance.”

Sign up for SimScale

and start simulating now