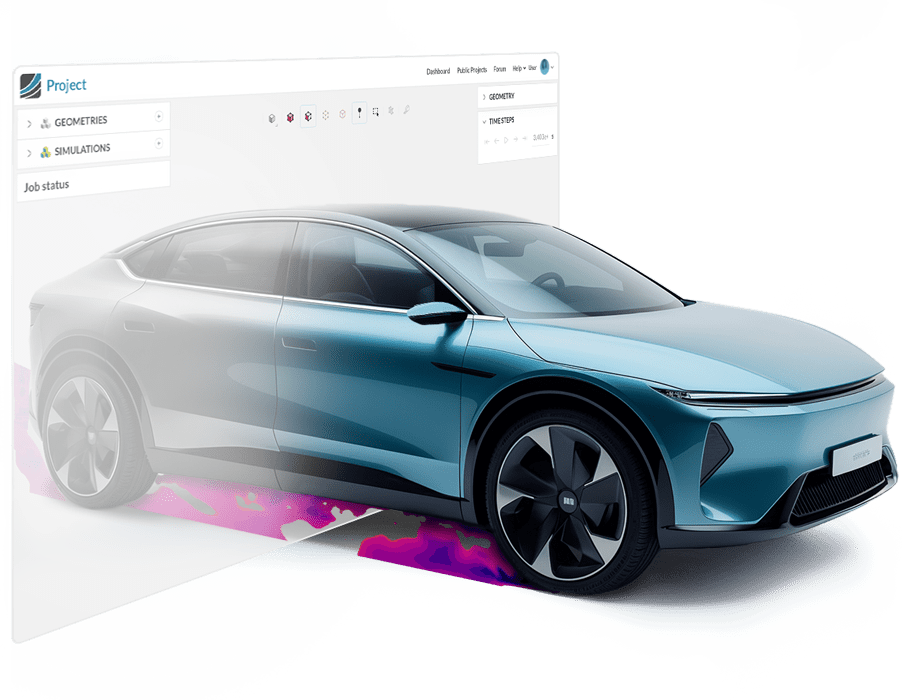

SimScale enables automotive engineering organizations to simulate earlier, broader, and faster and thereby deliver better designs earlier while improving engineering efficiency.

Cloud-native simulation’s HPC elasticity allows unlimited simulation sizes and simultaneous runs without the need to manage a data center. More simulations, faster, leads to compressed cycle times and faster innovation.

Cloud technology provides decentralized simulation use while maintaining central quality control. For the first time, users have safe and robust access to simulation.

Product lifetime

More power output

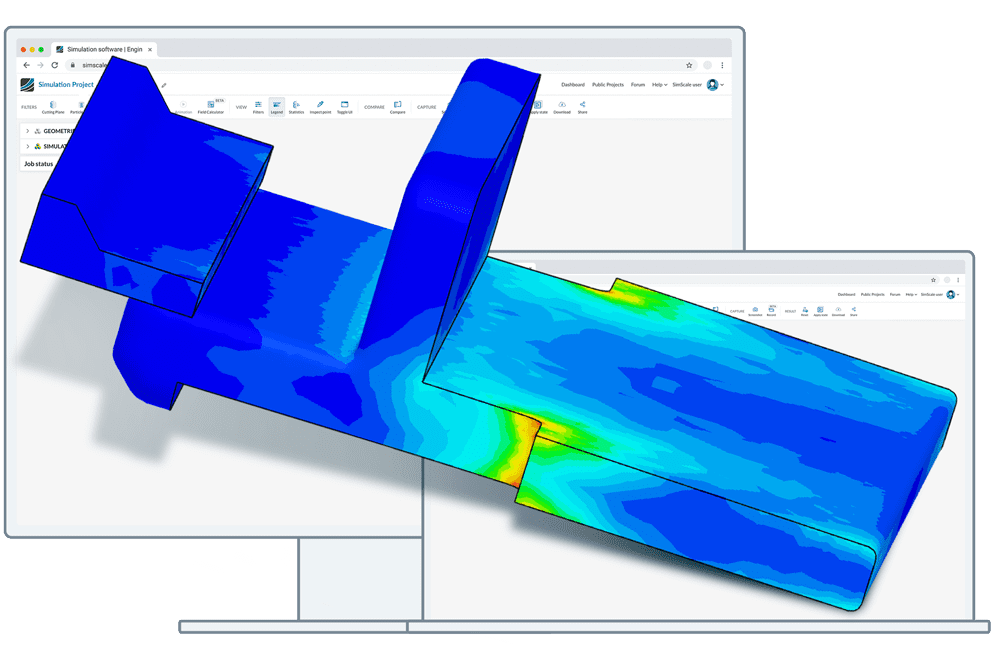

Lower pressure drop

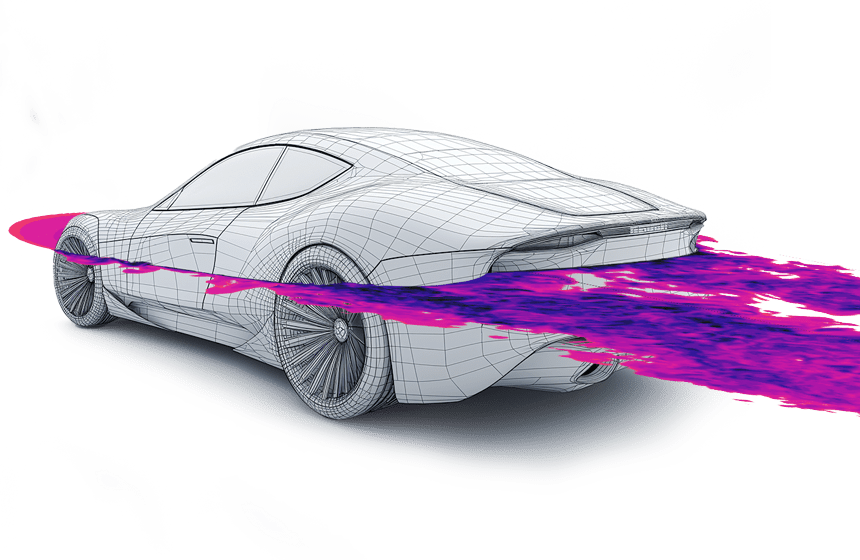

Lower aero drag

Force reduction

Faster design-to-prototype cycle

Faster development

Faster pre-testing

Faster time-to-result

Faster cycle time

Saved per experiment

Fewer prototypes needed

Lower costs vs. lab test

Lower hardware costs

Fewer lab prototypes

Material savings

Lower mfg. costs

Material savings (per unit)

Less energy used

Smaller turbine size

Learn more about how you can optimize your automotive design process with SimScale and get industry insights for free.

“Now we can innovate and test all the core functionalities (thermal, structural, and electrical) of the new high-voltage battery connector. We could not have developed this new product so fast without SimScale.”

“Using SimScale in the early R&D stages of the product, we were able to fully leverage simulation capabilities into our product design process.”

“The key advantage of using SimScale for us is to extract fast design insights at the early stages. We can then arrive at a final design faster and have more confidence when moving to the physical prototyping stage.”

Sign up for SimScale

and start simulating now