To better understand the model that produces values for the predicted mean vote (PMV) and the predicted percentage of dissatisfied (PPD), we should start at the beginning with the man who created them, Povl Ole Fanger. He hypothesized that human thermal comfort was based on one’s skin temperature and sweat secretion and that one could only be considered ‘comfortable’ if these two factors were balanced within a narrow range of acceptability.

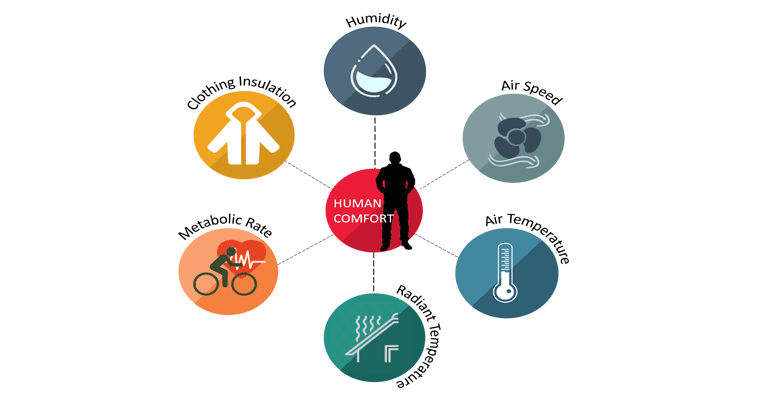

As humans, our thermoregulatory system modifies our temperature through involuntary responses. For example, sweating in high temperatures or shivering in cold temperatures to keep us thermally balanced and to avoid local discomfort. The human body can adapt to the external environment up to a certain range, but as soon as the limits are reached, the body’s responses are perceived as uncomfortable. Through climate chamber experiments, Fanger’s theory evolved to declare that thermal comfort could be found by evaluating the metabolic rate, clothing insulation, and environmental conditions of an individual.

Today, thermal comfort is defined as “that condition of mind that expresses satisfaction with the thermal environment” in the globally recognized ASHRAE 55 and ISO 7730 standards for evaluating indoor environments. To assess this condition, engineers must first determine the thermal sensation or thermal balance inhabitants of an indoor environment may feel in tangent with the thermal dissatisfaction experienced by occupants. These comfort limits can be expressed by the PMV and the PPD indices.

What Is PMV?

PMV is an index that aims to predict the mean value of votes of a group of occupants on a seven-point thermal sensation scale. Thermal equilibrium is obtained when an occupant’s internal heat production is the same as its heat loss. The heat balance of an individual can be influenced by levels of physical activity, clothing insulation, as well as the parameters of the thermal environment. For example, thermal sensation is generally perceived as better when occupants of a space have control over indoor temperature (i.e., natural ventilation through the opening or closing of windows), as it helps to alleviate high occupant thermal expectations on a mechanical ventilation system.

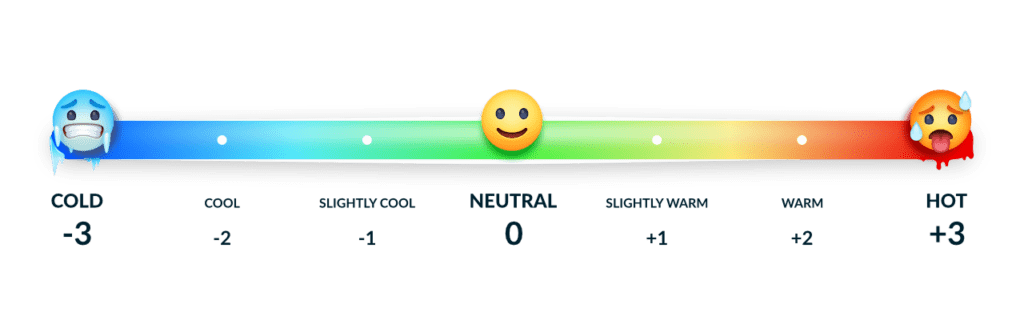

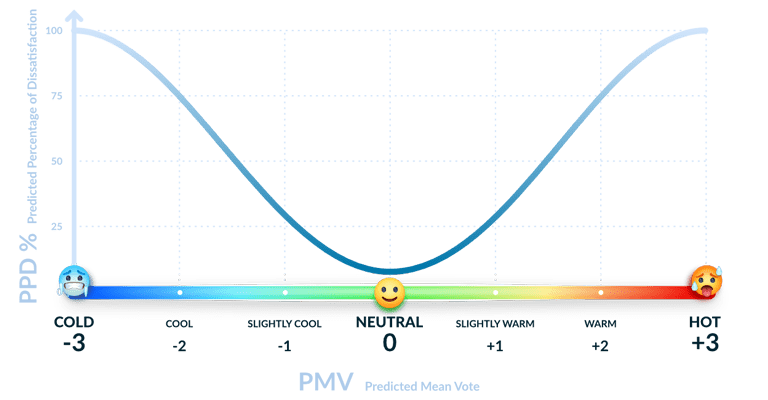

Within the PMV index, +3 translates as too hot, while -3 translates as too cold, as depicted below.

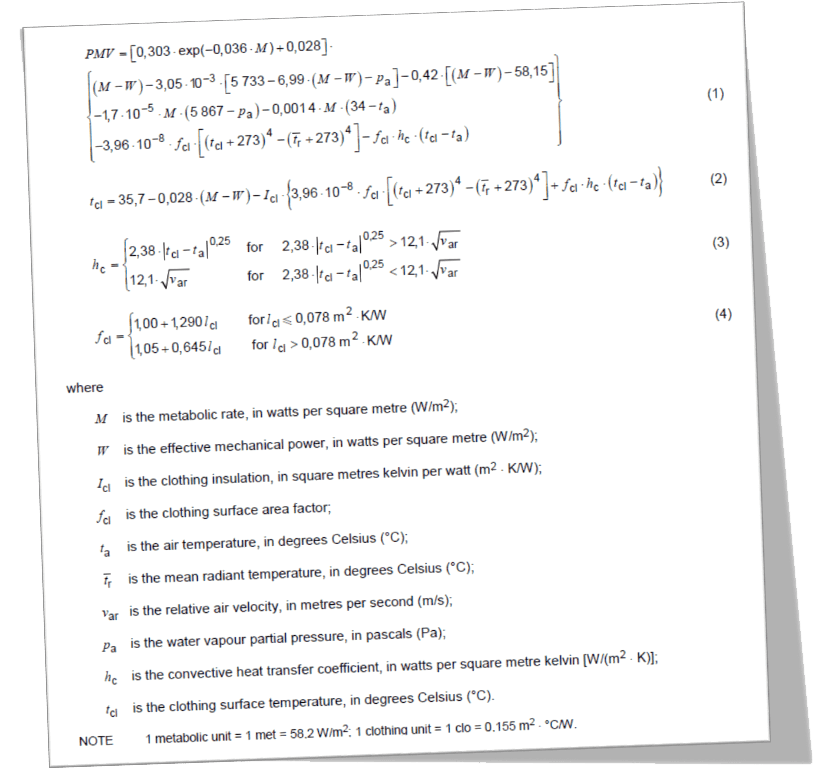

Different methods outlined in the ASHRAE 55 and ISO standards for certain types of environments can be used to assess and gather information for various combinations of metabolic rate, insulation, temperature, airspeed, mean radiant temperature, and relative humidity that factor into PMV.

In order to compute PMV, the simulated temperature and airspeed velocity (i.e., the ASHRAE/ISO standards recommend making an adaption for speeds above 0.2 m/s) of a given environment are used as inputs. These variables, along with given inputs for clothing insulation, relative humidity, and mean radiative temperature provide the basis to calculate PMV.

What Is PPD?

Through PMV, we can predict the thermal sensation of a population, but this doesn’t paint the whole picture. We also need to consider the level of satisfaction of the occupants in a space, to get a more holistic idea of if and how thermal comfort can be achieved. For this, Fanger developed another equation to relate the PMV to the predicted percentage of dissatisfied (PPD).

Once the PMV is calculated, the PPD, or index that establishes a quantitative prediction of the percentage of thermally dissatisfied occupants (i.e., too warm or too cold), can be determined. PPD essentially gives the percentage of people predicted to experience local discomfort. The main factors causing local discomfort are unwanted cooling or heating of an occupant’s body. Common contributing factors are drafts, abnormally high vertical temperature differences between the ankles and head, and/or floor temperature.

Acceptable PMV and PPD Ranges

Using both of these indices, ASHRAE 55 dictates that thermal comfort can be achieved based on an 80% occupant satisfaction rate or more. The remaining percentage of people can experience 10% dissatisfaction based on whole-body discomfort (all listed influencing factors of PMV) and 10% dissatisfaction based on local discomfort/partial body discomfort (includes fewer factors than whole-body).

In order to comply with ASHRAE 55, the recommended thermal limit on the 7-point scale of PMV is between -0.5 and 0.5. ISO 7730 expands on this limit, giving different indoor environments ranges. ISO defines the hard limit as ranging between -2 and +2, for existing buildings between -0.7 and +0.7, and for new buildings ranging between -0.5 and +0.5.

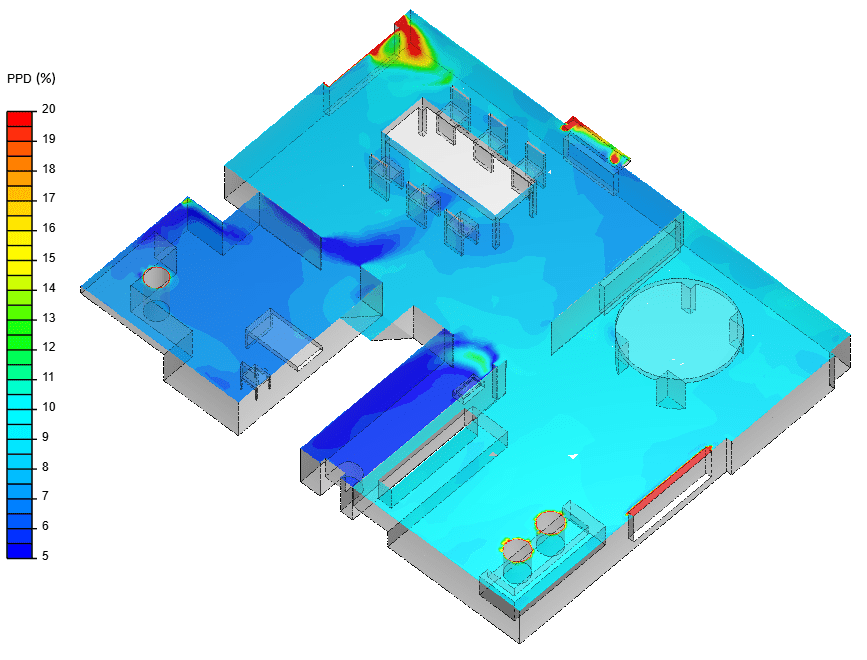

The PPD can range from 5% to 100%, depending on the calculated PMV. These comfort values will vary depending on where the occupant is located in the building. In order for comfort ranges to comply with standards, no occupied point in space should be above 20% PPD.

Explore CFD in SimScale

Conclusion

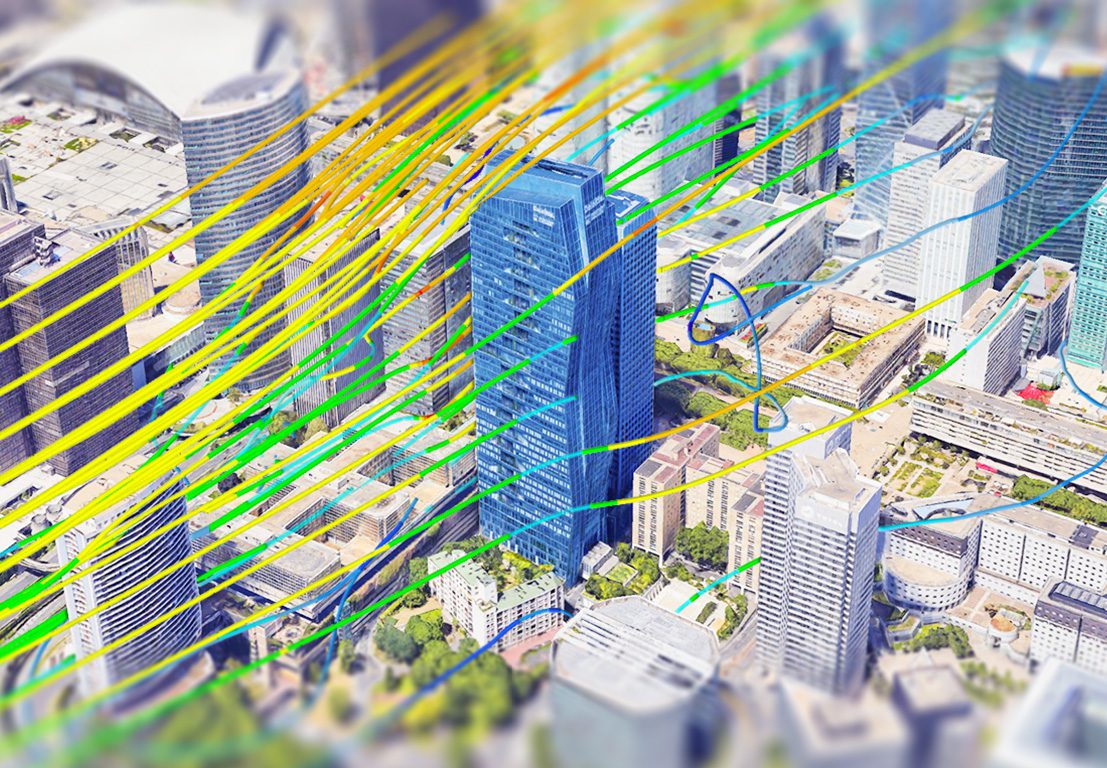

As a design or construction engineer, ensuring thermal comfort is often one of the prime objectives. So far, the success of this depended heavily on personal experience and the applicability of common methods for estimations. PMV and PPD can simply not conclusively be predicted in advance. With the emergence of engineering simulation tools in recent years, the guesswork has been removed from the equation, enabling anybody to test and optimize any given environment for thermal comfort compliance easily.

Based on these environmental and personal (clothing, metabolic rate) inputs, SimScale provides thermal comfort parameter outputs in the form of PMV and PPD fields, following the static model for determining the thermal comfort in a space. To learn more, refer to our Thermal Comfort Parameters documentation.

In order to comply with comfort standards, the aforementioned given ranges for each index must be met, and additional influencing conditions must be acknowledged. Achieving the thermal comfort of an environment is an innately cumbersome task, as the thermal environments of a space can change over time, and recommended limits cannot always be met, especially with the onset of climate change and unpredictable weather patterns.

While it is scientifically impossible to fully please everyone, the purpose of these indices is to try to please 80% of occupants in a given space, while mitigating factors that cause overwhelming discomfort.

Additional Thermal Comfort Resources from SimScale

- On-Demand Webinar: ASHRAE: Simulate Ventilation Equipment & Strategies Using Cloud-Native CFD

- Whitepaper: Simulating the Indoor Environment

- What Is ASHRAE 55? Basics of Thermal Comfort

- Thermal Comfort and Radiation with SimScale

- Radiation and Thermal Comfort for Indoor Spaces

- Ensuring Thermal Comfort with HVAC for a School Building Design: Case Study Ramboll

- ASHRAE Standard 55 Thermal Comfort Assessment with Simulation

- How to Comply With EN 15251 and EPBD – Thermal Comfort & More