Computer-aided engineering (CAE) is the broad usage of computer software in analyzing and virtually testing engineering products. With a CAE tool, you can simulate, validate, and optimize products based on the results of a numerical analysis.

CAE solutions are used in a wide range of industries to analyze the robustness and improve the performance of components and assemblies. At the same time, engineering simulation is the major support for design teams in product optimization.

Nowadays, an integration between CAD and CAE has become a necessary part of the everyday workflow for design engineers. Using the SaaS version of both solutions can reduce the differences, allowing the possibility of creating a CAD model and running engineering simulations with minimal effort.

A CAE simulation session generally includes three main phases:

- Pre-processing – Upload of CAD model, defining the model and environmental factors

- Running solvers applications – Based on simulation analysis algorithms

- Post-processing – Validation of the model and 3D visualization

Sign up and check out our SimScale blog for much more!

Main Benefits of CAE

The main benefits offered by CAE/engineering simulation are:

- Reduced time in product development

- Improved product quality and reliability

- Risk reduction

- Possibility to make corrections early in the concept and design phases

- Dramatic reduction in the costs associated with physical testing of prototypes

- Keeping the established deadlines in different phases of the engineering workflow

- Radical improvement of product quality and reliability, thus raising the customer satisfaction level

- Product lifecycle extension

Types of CAE Analyses

With CAE, there is a large spectrum of engineering simulation analysis types to consider, including:

- Stress and dynamics analysis using finite element analysis (FEA)

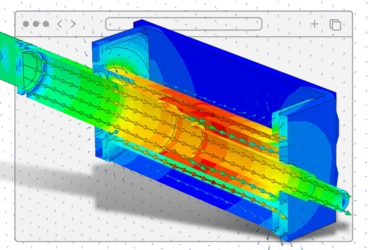

- Thermal and fluid analysis using computational fluid dynamics (CFD)

- Kinematics and dynamic analysis of mechanisms (multibody dynamics)

- Acoustics analysis using FEA or a boundary element method (BEM)

- 1D CAE, or mechatronic system simulation, for multi-domain mechatronics system design

- Simulation of manufacturing processes like casting, molding and die press forming

- Particle simulation as part of a flow industrial process

- Multiphysics analysis based on multiple simulation phenomena

- Optimization of the product or process

Large Applicability of CAE

All these CAE tools are used in the simulation, validation, and optimization of products with applicability in many industries, including automotive, aerospace, energy, plant engineering, industrial equipment, HVAC, electronics, and consumer goods.

Engineering simulation has a wide range of applications, from small components or products to complex appliances, plants, HVAC equipment, and heavy machines. Here are some examples from the SimScale Public Projects Library:

- Equipment and machine components: static structural analysis of a gripper arm, different stress scenarios applied to a bike frame, dynamic analysis of a simplified crank-piston mechanism, transient thermal analysis for a car braking system, or thermostructural analysis of a router part.

- Consumer products: convective flow inside a light bulb, nonlinear static structural analysis of a plier, contact analysis of a consumer snap-fit mechanism, or a mobile phone casing tested after a two-meters drop.

- Equipment and machines parts from an industrial process: water flow through a globe valve, centrifugal water pump using the multiple reference frame method (MRF) or sloshing of fuel inside a moving fuel tank.

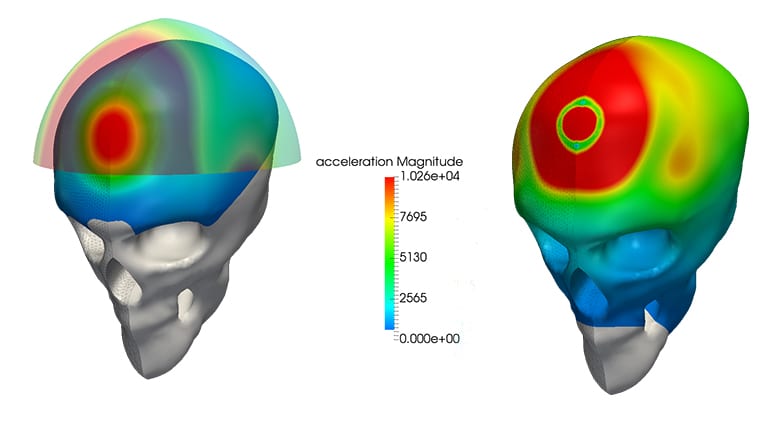

- Dynamic behavior of different machine systems, building structures, or natural bodies: aerodynamics analysis of a F1 race car, airflow simulation around a LMP1 race car, human skull impact with and without a helmet, hydrodynamic performance of a dolphin swimming close to the surface of water, external fluid flow around a submarine, airflow around a motorbike, or compressible aerodynamics of commercial aircraft.

- Complex process analysis: water purification process in a maze channel reactor, exhaust pollution gases through a chimney of a plant, or natural convection of heat from a refrigerator’s condenser coils.

All the projects presented in this article can be imported into your own workspace from SimScale’s Public Projects and used as templates.

If you haven’t signed up for SimScale yet, you can create your free account here and see for yourself how 3D engineering simulation can help you increase the performance of your engineering activities in any industry.

The purpose of a helmet is to protect the person who wears it from a head injury during impact. In this project, the impact of a human skull with and without a helmet was simulated with a nonlinear dynamic analysis. Download this case study for free.