In October 2024, SimScale hosted a webinar that dove into the pressing challenges in EV battery simulation & manufacturing and how cloud-native simulation can accelerate innovation in battery pack design. Here are the top five highlights from the session on EV Battery Manufacturing.

On-Demand Webinar

If the above highlights caught your interest, there are many more to see. Watch the on-demand Engineering Leaders Series webinar from SimScale on Challenges in EV Battery Manufacturing by clicking the link below.

1. AI’s Role in Redefining EV Battery Manufacturing

Jeremy Ewald, Founder of EV Tech Insider, shared insights on how artificial intelligence (AI) is transforming the battery production process. One standout example was Microsoft’s AI-driven research, which accelerated the identification of solid-state electrolyte compounds, reducing what would have taken years into just hours. This exemplifies how AI is speeding up material discovery and optimization, especially in EV battery manufacturing, where innovation cycles are critical.

2. Growth in U.S. Battery Manufacturing Capacity

Ewald also covered the massive expansion of EV battery plants across the U.S., a development that’s set to bring jobs and opportunities to once-declining automotive regions. From Michigan to Georgia, new plants are rising, and many of these are leveraging AI and machine learning to enhance production efficiency, materials research, and battery validation.

3. Connector Innovations for Efficient Battery Pack Design

The presenters highlighted the challenges of standardizing high-power connectors for EV batteries. They emphasized how their innovations, such as quick connectors that reduce weight and improve assembly efficiency, play a crucial role in advancing the reliability and performance of battery packs. These connectors offer sustainable, recyclable solutions and support efficient high-voltage routing—crucial for the EV industry.

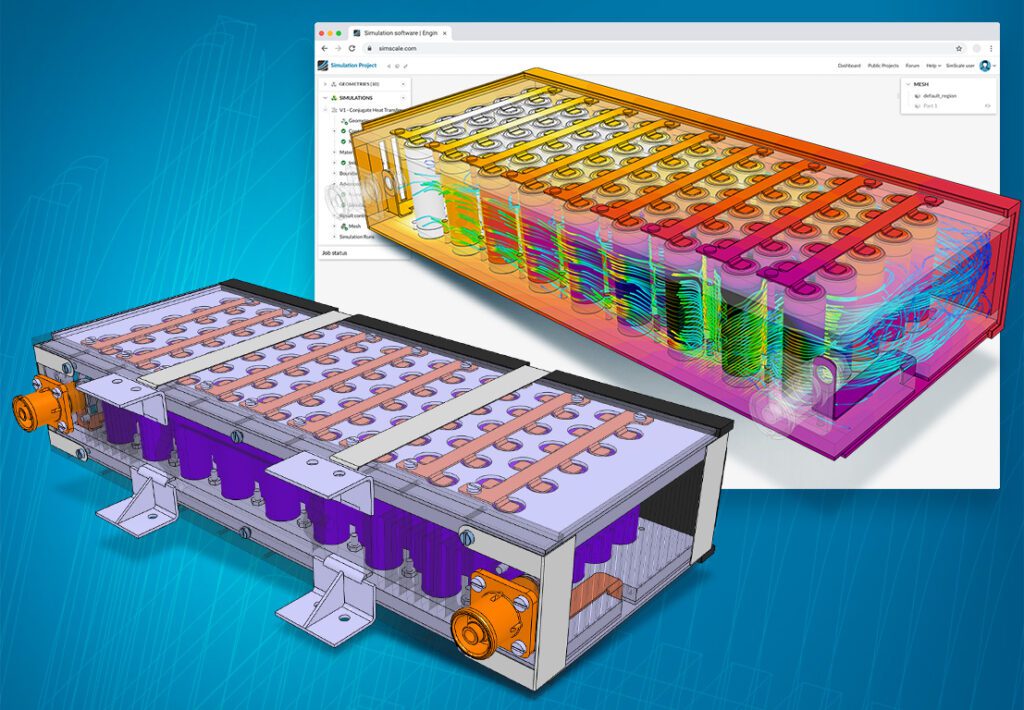

4. The Importance of Simulation in High-Power Connector Design

One of the key points discussed was how cloud-native simulation, such as that offered by SimScale, is essential for connector design. The presenters showcased the value of running structural, thermal, and electromagnetic analyses that correlate with real-world testing. By doing this all on one platform, automotive companies can significantly reduce product development times while ensuring performance stability and compliance with evolving industry standards.

5. Standardization Challenges in the EV Industry

The presenters agreed that a lack of standardization in battery pack design is one of the industry’s largest obstacles. With every OEM (original equipment manufacturer) having different design requirements, it’s challenging to create universal solutions. This lack of standardization also affects long-term reliability, especially in areas like battery connectors, where inconsistent designs can lead to overheating or failure over time.

Driving Innovation in EV Battery Manufacturing

The future of EV battery manufacturing is being shaped by innovations in AI, cloud-native simulation, and connector technology. Overcoming challenges like standardization will require collaboration across the industry, but the potential for faster, safer, and more efficient production is within reach. Companies that embrace these advancements will not only streamline their processes but also lead the way in driving the next era of electrification. The road ahead is clear—innovation is the key to staying ahead in this rapidly evolving landscape.