As global industries push for smarter, faster, and more efficient product development, the integration of AI into simulation workflows is becoming a game-changer. Last week, SimScale hosted an insightful webinar on “AI-Powered Valve Design & Optimization,” exploring how AI integration transforms valve design workflows, enhancing efficiency and accuracy. Dr. Naghman Khan, Product Marketing Manager, and Ajitkumar Ananthu Jeyakumar, Senior Application Engineer at SimScale, led the session, showcasing how cloud-native simulation and AI come together to deliver optimized solutions for valve performance. In case you missed it, here are the top 5 highlights from the webinar.

On-Demand Webinar

If these highlights caught your interest, there are many more to see. Watch the on-demand Simulation Expert Series webinar from SimScale on AI-powered valve design & optimization by clicking the link below.

1. AI-Enhanced Workflow: Faster Insights, Better Decisions

The webinar demonstrated how SimScale’s integrated AI simplifies complex workflows. By leveraging pre-existing simulation data, users can train AI models to predict results in seconds. For example, instead of running separate analyses for each valve position or flow rate, engineers can now rely on AI to produce real-time predictions, drastically reducing lead times.

Key takeaway: AI models trained directly within SimScale’s platform eliminate the need for external tools, allowing engineers to make quick, data-driven design decisions.

2. Bridging Gaps for All Engineers

Ajit introduced personas like Tom, a structural engineer unfamiliar with fluid dynamics, and Jerry, a system-level designer needing precise input for process models.

SimScale’s AI tools support both by simplifying access to CFD and structural analysis data. Users can start with customizable templates, minimizing setup time and focusing on insights.

Key takeaway: SimScale democratizes simulation, empowering both novice and experienced engineers with intuitive, guided workflows.

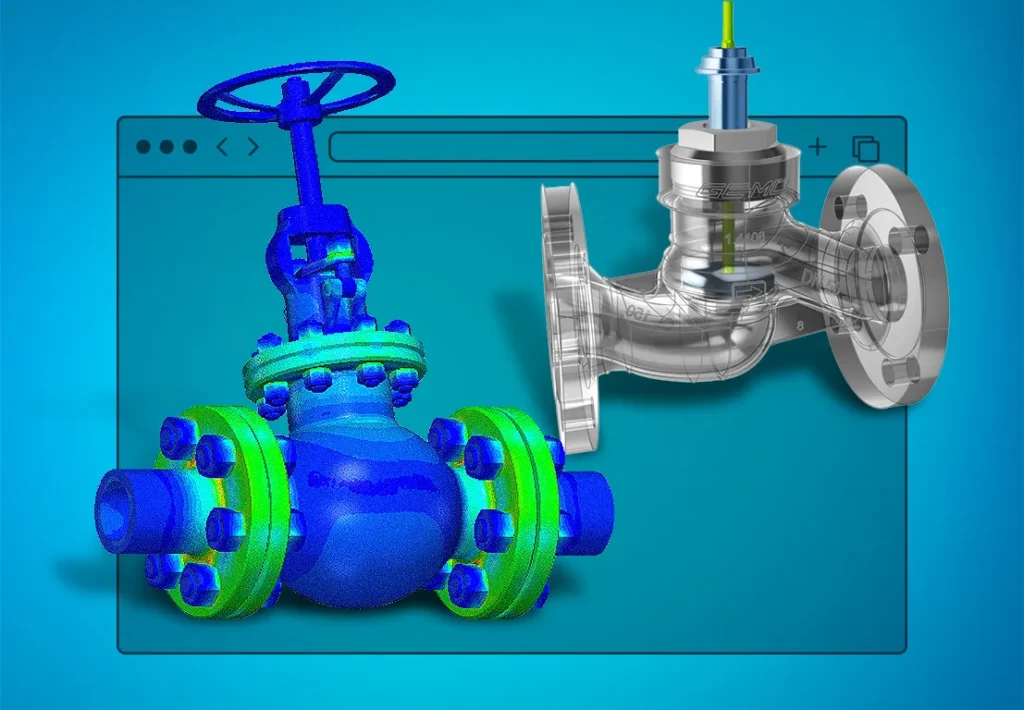

3. Case Study: Predicting Valve Performance with AI

The session highlighted a globe valve design where AI predicted pressure drops and forces across various operating conditions. Using 117 design samples, the AI model delivered results with over 90% confidence. Engineers could also validate predictions by comparing them with traditional CFD results, ensuring accuracy.

Key takeaway: AI-based predictions reduce simulation runtimes while maintaining reliability, making them ideal for early-stage and iterative designs.

4. Seamless Integration of Simulation Data

SimScale’s cloud-native platform allows users to toggle between high-fidelity simulations and AI-driven predictions seamlessly. Ajit showcased how results from CFD analyses could be directly integrated into structural simulations for further evaluation without data transfer hassles.

Key takeaway: A unified platform ensures smoother transitions between analysis types, enhancing productivity and collaboration.

5. AI Beyond Valves: Versatility Across Applications

While valves were the focus, the webinar touched on broader applications of AI in simulation. From pumps to structural components, SimScale enables engineers to train models for diverse use cases. This flexibility extends to system-level design, where AI predictions integrate seamlessly into process models via APIs.

Key takeaway: SimScale’s AI capabilities adapt to various industries, supporting innovation across product development.

Why AI in Valve Design is the Future

SimScale’s webinar on AI-Powered Valve Design & Optimization showcased the future of engineering workflows: faster, smarter, and more collaborative. By embedding AI into cloud-native simulation, engineers can overcome traditional bottlenecks and unlock new possibilities.

If you missed the webinar or want to learn more about integrating AI into your workflows, watch the webinar on-demand or contact our team below.

What aspect of AI-powered simulation excites you the most? Let us know!