In this SimScale student success story blog, we speak with the Waseda University Formula Student Team about their remarkable transformation in aerodynamics using SimScale. This story captures the journey of the Waseda University Formula Student Team, highlighting their challenges, approach, and the pivotal role SimScale played in transforming their aerodynamics development. Ryu answers some of our questions regarding their experience with the SimScale platform as a team.

Waseda Formula Team, a dedicated group of 20 members, competes in Formula Student Japan. This esteemed event gathers around 70 national teams alongside 30 international contenders. In 2022, they secured a commendable 6th place in Autocross, advancing to the Final 6 endurance event. In 2023, despite significantly improving their Autocross performance, they narrowly missed the Final 6 due to ongoing endurance challenges, showcasing their remarkable progress and determination.

“SimScale opened our engineering possibilities and revolutionized our workflow”.

-Ryu, Waseda Formula Team

The Waseda Formula Student team may be smaller in size compared to other teams in Formula Student, yet they shine brightly with an incredible sense of unity. Driven by their love for combustion vehicles, they delight in discovering fresh ways to get better even with limited resources.

The Problem: Engine overheating

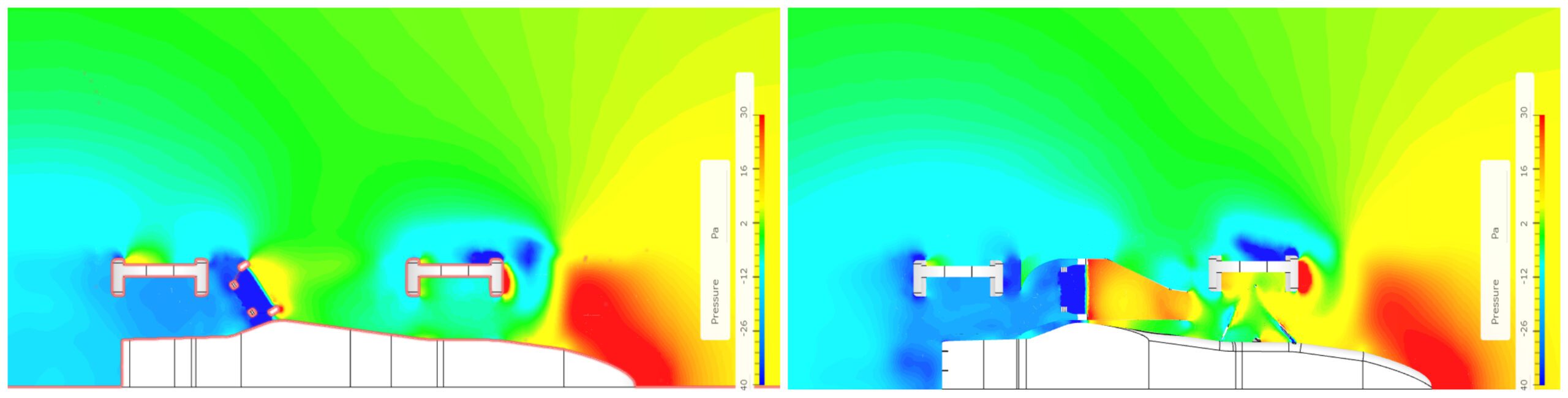

While maintaining a steady pace in Autocross, the team encountered a significant challenge—endurance remained unconquered in both 2022 and 2023 due to persistent engine overheating issues. After further investigation, the root cause was identified: inadequate airflow through the radiator and suboptimal side pod design, hindering maximum cooling efficiency.

Addressing this obstacle demanded a deep analysis of airflow dynamics through the radiator and optimization of the side pod configuration for enhanced cooling capacity. For a team like theirs, limited in computational resources and CFD expertise, conducting a precise car simulation mirroring radiator characteristics and fan behavior proved challenging.

In their pursuit of a solution, the team found SimScale. Through a few simulation runs, they witnessed the impressive capabilities of the platform, realizing its potential to significantly aid their efforts.

“First, it allowed us to run a full model car simulation at ease, which normally took days to finish with our weak computer resources. Second, it has one of the best user-friendly interfaces and rich supporting environment from the SimScale team. “

-Ryu, Waseda Formula Team

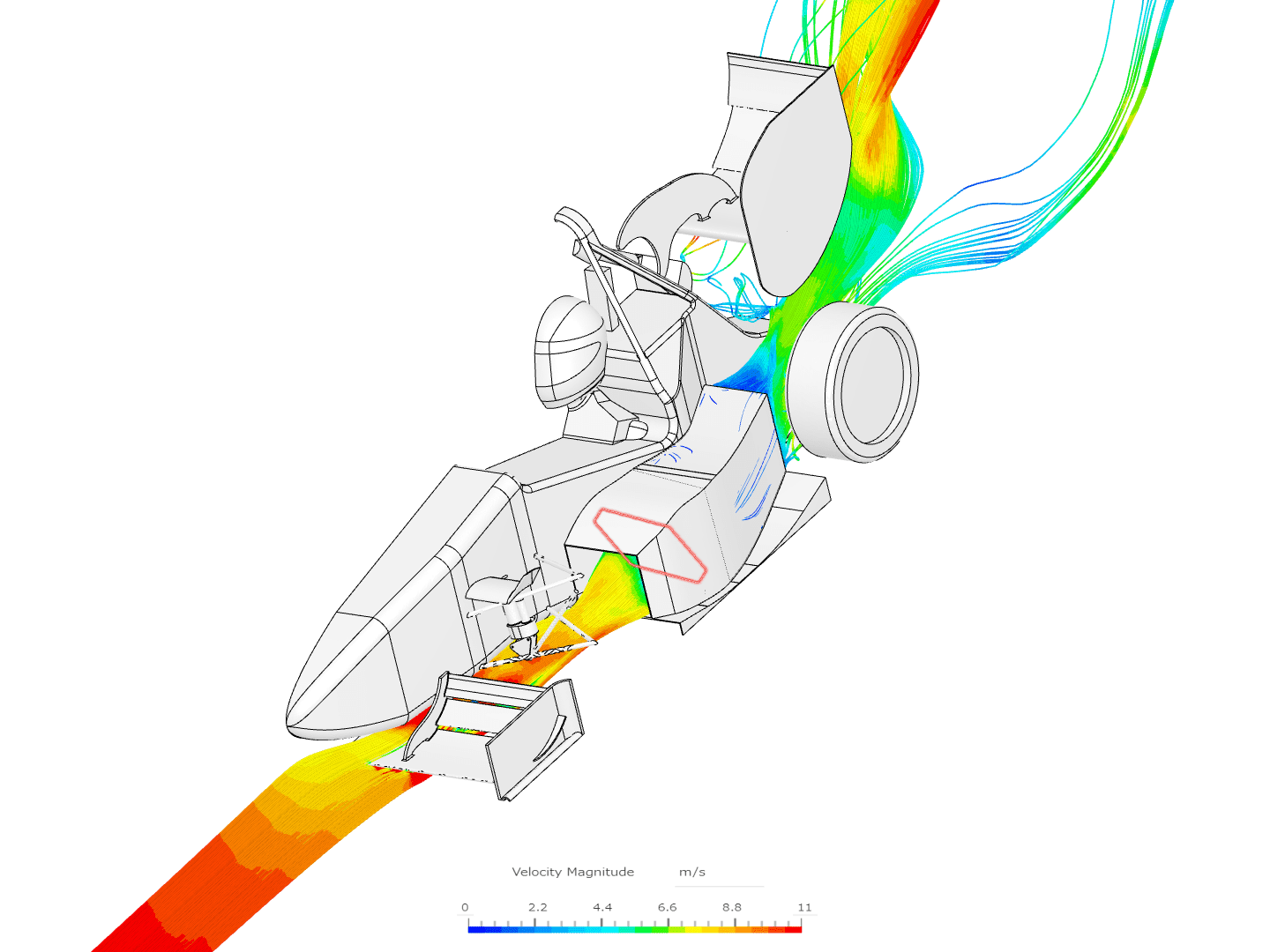

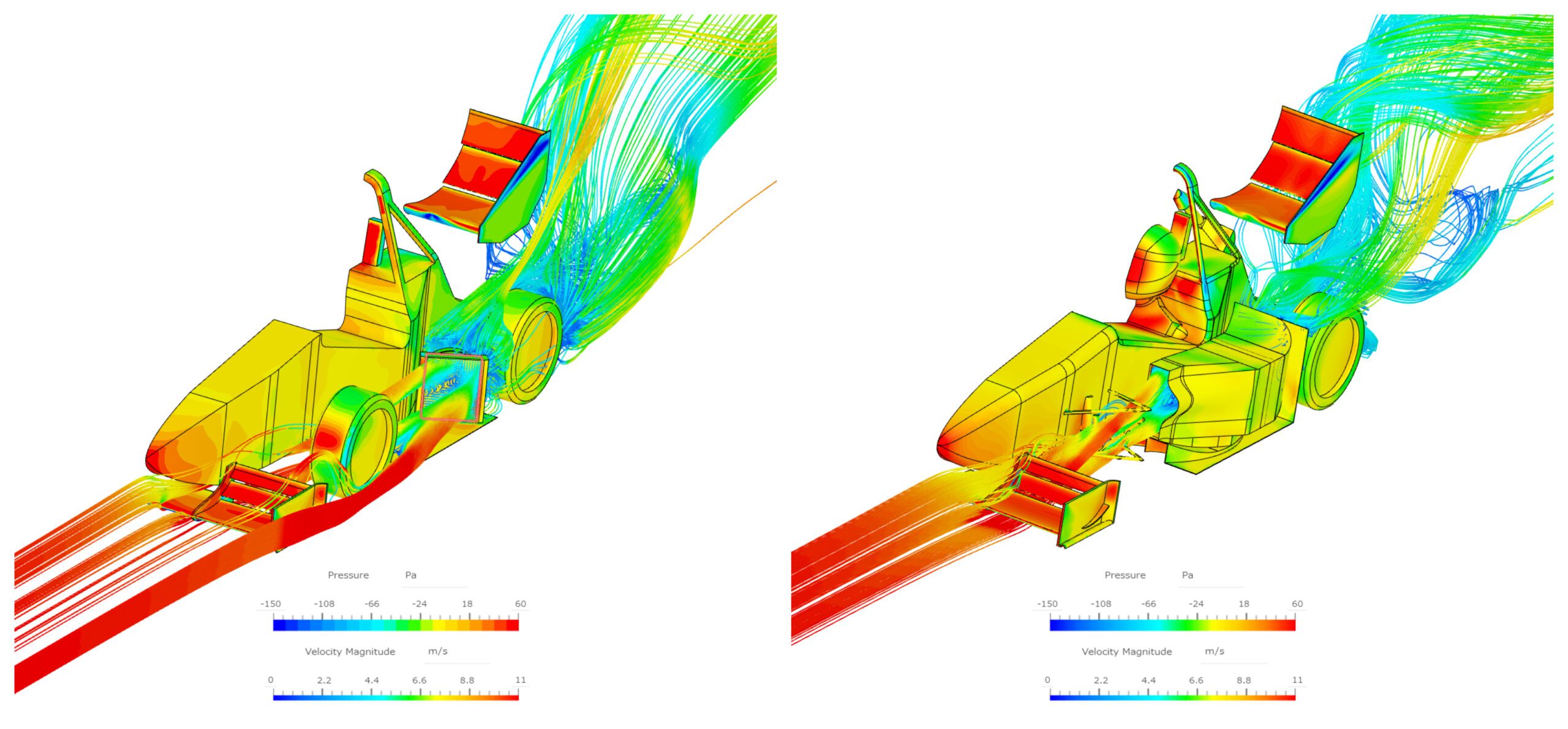

How They Solved It: SimScale Incompressible Simulations

The simulation of airflow around the FSAE car was set up based on the tutorial “Incompressible Flow around a Formula Student Car” provided by SimScale. The tutorial, which they found to be reliable and easily comprehensible, helped a smooth transition from the previous CFD software to SimScale. In their simulation runs, they used the incompressible simulation type with the k-omega SST turbulence model to simulate the car’s operation at 11 m/s. To mimic the radiator, Porous media: Darcy-Forchheimer medium was utilized, adopting coefficient values from the tutorial. For the radiator fan, they used Momentum sources: Fan model, integrating the performance data of the specific fan employed for their car.

“We were pleasantly surprised with the high capabilities of the SimScale CAD editing tool. We were able to switch to SimScale from previous CFD software without any problems whatsoever, and were surprised with the rich variations of CFD tools that were prepared.”

-Ryu, Waseda Formula Team

They’ve conducted approximately 30 simulations for radiator cooling analysis, each taking around 4 to 5 hours and consuming approximately 80 core hours. Their focus on development speed over quality during the initial design phase is reflected in their relatively lightweight mesh settings. They employed a standard meshing algorithm set at level 5 fineness and activated the hex mesh core settings, generating approximately 3 million nodes.

At this point, compared to the initiation of their project, they’ve achieved a notable 40% increase in radiator airflow—a figure aligned with their initial calculations. Obtaining accurate airflow volume data posed challenges with previous CFD software. Yet with SimScale, making use of the Cutting Plane and Statistics features made this task effortless. Moreover, the extensive customization options in result filters enabled them to precisely identify and comprehend issues in each simulation.

By continuously refining their design through the SimScale platform, they managed to achieve remarkable progress!

They noticed that SimScale improved the flexibility, productivity, and time efficiency of their aerodynamics development, completely transforming their engineering process. Within a short period, it allowed them to achieve their initial engineering goals.

“With SimScale, once the simulation begins, you’re free to close the tab and continue working on other tasks using your PC. We frequently created CAD models for other simulations concurrently while running SimScale. Plus, because the simulations are cloud-based and not limited to specific computer resources, they can be accessed and reviewed from any device and location. This significantly boosted team productivity, making CFD simulations available anytime and anywhere.”

-Ryu, Waseda Formula

Next Steps for Waseda Formula Student

The Waseda Formula Student team plans to persist in their efforts, continuing to further explore and refine the rapid rough design to final shape. Their aim is to enhance precision and elevate mesh quality for a more refined final product.

We are sure that the wide range of simulation capabilities within SimScale will be beneficial for the Waseda Formula Student team for future applications, and we are looking forward to cooperating with them in the future. If your team is also interested in an academic sponsorship to enhance the performance of your vehicle – no matter if it is in Formula Student or any other competition – make sure to check out our Academic Plan for students who are joining design competitions.