Thermal analysis is an important aspect of modern design. Many fluids, materials, and structures have temperature-dependent characteristics that impact strength, performance or thermal comfort in their design. Whether testing a new product, optimizing electronics’ performance, or assessing thermal comfort in a building, heat—and more precisely, overheating—is a primary concern for many engineers. For this reason, a thermal analysis tool is used in the early design stages of most applications.

Thermal Analysis Software: Where to Begin?

Thermal simulations are predominantly used for quality control, research and development, and failure analysis when it comes to physical products. It may also be used to evaluate materials—new or existing—to see how they will perform at different temperatures or with new production methods—additive manufacturing is one example. Thermal analysis also includes testing fluids as well as heat transfer via a fluid. For example, thermal analysis software can help show how hot or cold air is affecting thermal comfort in an indoor space, or investigate how it is transferred within a printed circuit board (PCB) and how it affects delicate components. There are many types of thermal analyses, so how do you know which type you need? One way to break down the types of thermodynamics simulations available is by considering what you are investigating; solids, fluids, or both.

Testing Solids: Thermal Structural Analysis with FEA

Most failures could have been avoided during the design phase, and a lot of the time this is due to how the product or material reacts to heat sources. Crystallization, melting, expansion or shrinkage; some results of extremely high or low temperatures can cause dramatic reactions in materials, and therefore cause breaking, buckling, or distortion of the products.

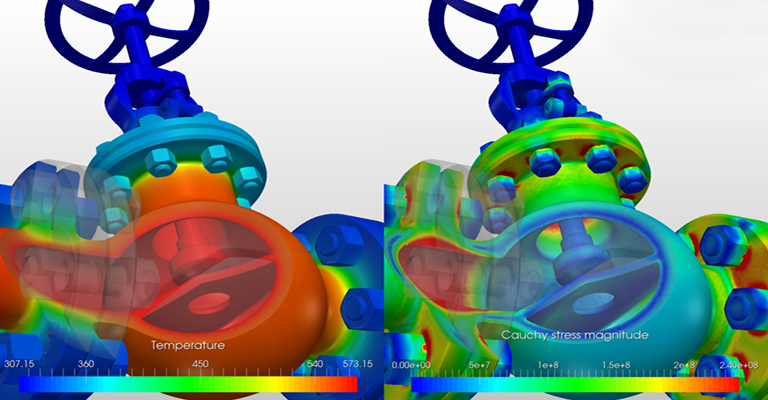

To avoid this, solids can be thermally tested with thermomechanical simulation. In solids, a conduction heat transfer analysis can reveal, among other things, higher and lower temperature fields, how a material conducts or insulates heat, how the solid reacts to thermal load or how increased pressure load causes temperature changes in the solid. These can be investigated with a steady-state analysis or a transient one if testing for time-dependent effects. Understanding these aspects helps to design a product that is safe, reliable, durable, and high-performing, in the temperatures and conditions that it is being created for.

This transient, static nonlinear, uncoupled thermomechanical analysis of a globe valve demonstrates temperature and stress distribution at different intervals of interest. View the project in the SimScale public project library here.

THERMAL ANALYSIS SOFTWARE Fluid Flow Analysis: Convective Heat Transfer

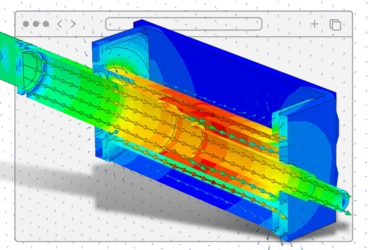

Using a thermal analysis tool, you can also simulate how thermal energy is carried onto a fluid. This shows how heat transfer is achieved by particle movement in fluids and gases which are classified as convection heat transfer. Convection mostly depends on the ambient fluid or gas temperatures and their movement. Take, for example, mechanical/forced ventilation. If you mechanically blow cold air through a room, it will take the hot air out of an outlet. This is to do with the density of air at different temperatures.

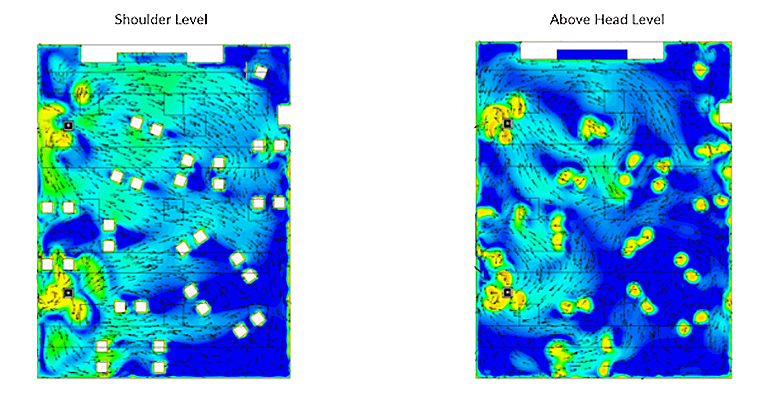

Another example is natural or passive ventilation. A common phenomenon often simulated in this type of analysis is stack effect, where differences between internal and external air pressures caused air to be drawn out of a building. Stack ventilation is just one of the many topics of airflow and heat simulation that are driving the trend of CFD in the HVAC sector. A convective heat transfer analysis is helpful for HVAC engineers and designers looking to simulate smoke extraction or create the best possible thermal comfort through an HVAC system in an indoor environment. Temperature differences between surfaces and the ambient temperature cause hot air particles to move and therefore transfer heat. Using a heat simulator, a designer can identify the heat transfer amount which is usually calculated as surface temperature minus ambient temperature.

In this HVAC example, you can see how convection is simulated to analyze thermal comfort conditions in a school building.

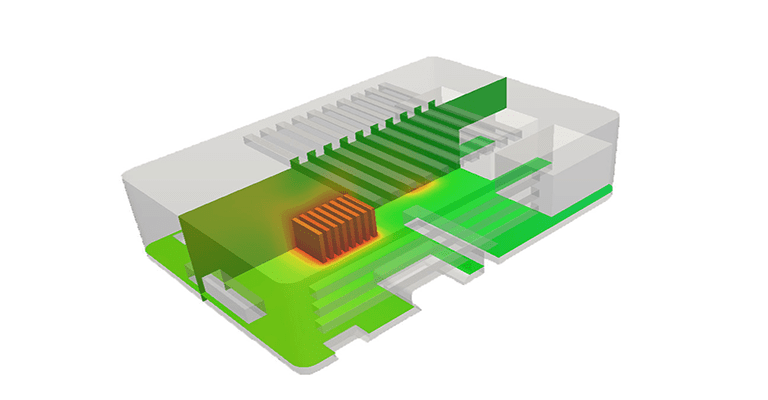

Conjugate Heat Transfer: Thermal Analysis Tool for Solids and Fluids

The analysis type conjugate heat transfer (CHT) allows the simulation of the heat transfer between both solid and fluid domains by exchanging thermal energy at the contacts between them. For example, hot water flowing through a copper pipe would cause the copper to become hot, or cooled air covering a heated object would help the object to cool down. Conjugate heat transfer is of particular use for electronics cooling, heat exchangers or cooling of data centers. Heat sinks, for instance, are important to the performance of many electronic applications and are often simulated to ensure that they keep the electronics they are supporting cool enough to function properly.

Take a look at this Raspberry Pi example to learn how heat sinks dissipate heat energy away from devices to regulate temperature to ensure better performance.

Additional Considerations with Radiation

Radiation is an interesting heat transfer phenomenon as it does not require a medium. Radiation is the transfer of energy using electromagnetic waves. When this energy impacts matter, it generates heat (find documentation here). Radiation is particularly prominent at higher temperatures and so is often used for applications such as outdoor thermal analysis, solar heat transfer, or high-temperature electronics. Enabling radiation in simulations for these types will ensure that surface emissivity is included in calculations and your results can provide a more accurate estimation of how the product will react once in use.

Overall Benefits & Conclusion

Depending on the thermal analysis type you require, you might then decide whether you require finite element or finite volume analysis. The difference between the two relates to the meshing of your design model before you begin simulating. In the case of CFD, which is predominantly used for convection, the variable interest is stored at the center of the volume or flow domain. Thus being called finite volume analysis. Simulations where solids are concerned, such as for thermomechanical or structural analysis, the variable of interest being tested is placed at the core of each node—finite element. Take a look at this video for more information. Using thermal analysis software reveals the behavioral properties of products and designs under thermal load, stress or velocity in order for you to make informed decisions. Based on the simulation results, you should then be able to ensure better efficiency, performance, and/or reliability in your final design iteration.

If you require more detailed information on heat transfer simulation, make sure to take a look at our documentation here. SimScale is your cloud-based thermal analysis tool and can support you with all kinds of thermal analysis directly in your web browser.