Founded in 2015, Team Supernova is a Brazilian team consisting of approximately 50 students from various disciplines at the Federal University of Juiz de Fora (UFJF), one of the country’s most esteemed institutions. The group operates as a non-profit organization dedicated to the design, production, and launch of small rockets, applying the principles of full-scale rocketry on a reduced scale.

The team’s mission is to develop and enhance its members’ skills through hands-on experience in model rocketry, with the goal of becoming a national leader in the field through the successful execution of projects and achievements in competitions. In every aspect of their work, Supernova upholds core values: a relentless pursuit of knowledge, commitment, unity, a collaborative spirit, and a deep sense of pride in being part of Supernova.

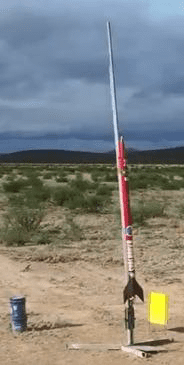

In 2024, Supernova made its debut at the world’s largest rocketry competition, the Spaceport America Cup, where 152 teams from various countries gathered in New Mexico, USA, to launch their projects. The team’s mission aimed for a 10,000 ft apogee using a solid-fuel rocket named Aspera, which earned them an impressive 6th place in their category and 23rd place in the overall team rankings. This achievement marked a significant milestone for Supernova and its members, representing a proud and memorable victory.

Before participating in the Spaceport America Cup, Supernova made significant strides in Brazil by actively engaging in regional competitions and national research assemblies. However, the team’s primary focus has been the Latin American Space Challenge (LASC), an international competition where they have achieved notable successes in previous years. Their next target is LASC 2024, in which they plan to launch a rocket with a 10,000-ft apogee in a new mission featuring a CanSat payload.

Incorporating Computer-Aided Engineering (CAE) into Supernova’s operations has proven to be a key solution to challenges encountered in previous projects. The team had faced difficulties validating components through physical tests due to a lack of access to necessary structural conditions, leading to wasted materials and financial resources on parts that ultimately proved non-functional.

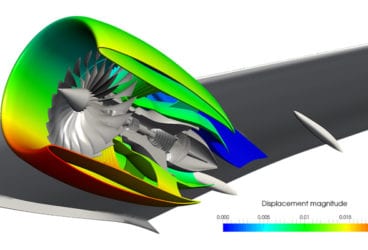

To address these issues, Supernova established the Simulations and Research (SIMP) division, tasked with analyzing rocket components through computer simulations. This process ensures the validation of both the design and physical aspects of the project while also fostering innovation, optimization, and resolving problems encountered in earlier stages.

Prior to using SimScale, we used other CAE software programs that had major problems like outdated layout and bad mesh tools mechanics, which used to make the work harder and result in bad mesh quality. However, SimScale provides a good mesh creating and improving systems and an updated layout, that makes the process a lot easier.

– Team Supernova Rocketry

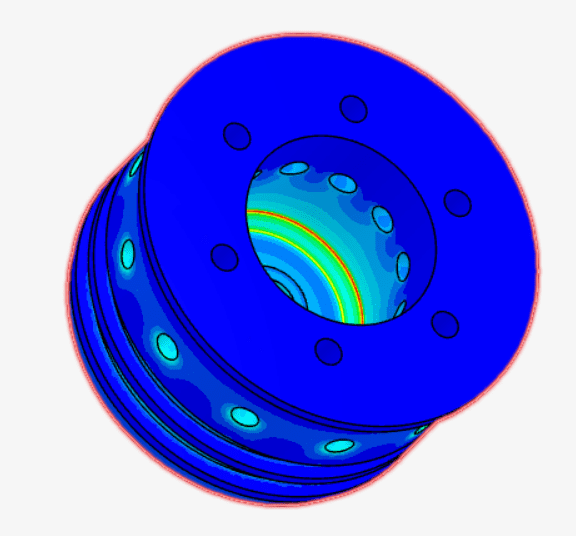

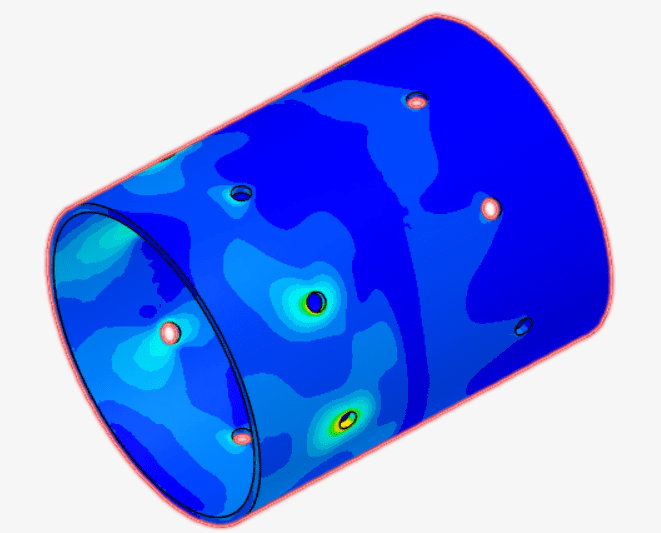

Some of the components that required simulation included the motor’s bulkhead (which needed to withstand the pressure generated upon ignition), the recovery module’s junction (designed to bear the rocket’s weight), and the motor’s casing (intended to withstand the motor’s internal pressure).

Initially, separate static simulations were created for each component to analyze whether the aluminum used would meet these demanding conditions. The geometries were imported individually, without any other rocket parts, making contact definitions unnecessary. For all components, the material was defined, and fixed supports were applied where the screws would be located. Boundary conditions were applied as required: the bulkhead was subjected to the motor’s pressure at its base, the casing received internal pressure on its inner surfaces, and the junction was subjected to forces above and below it via a remote force calculation, considering the center of mass.

Several simulations were conducted to analyze the bulkhead, recovery module’s junction, and motor’s casing, focusing on their ability to withstand pressure and weight. For the bulkhead, multiple iterations with varying node sizes were run until the results converged, with the final simulation using around 1,000,000 nodes in 20 minutes, confirming the component’s safety via Von Mises stress analysis. The recovery module’s junction, though not fully analyzed due to time constraints, showed no stress exceeding the material’s yield strength after a 25-minute simulation with approximately 300,000 nodes. Similarly, the motor’s casing, analyzed with 1,500,000 nodes in 20 minutes, was deemed safe through Von Mises stress evaluation, as the stress remained within the allowable limits.

It is impossible to write in words how Simscale changed Supernova. Since we have adopted it, the process of simulating has gained a lot of improvements, shortened the time needed to set up the analysis and to calculate the problem, decreased the work to create and improve mesh by better algorithm creation and tools, and in the end, by having online mechanics, made it possible to work when we had problems with other software programs and our own computers.

– Team Supernova Rocketry