Comprised of high school students from the local community, Team RoboCorns of Exton, Pennsylvania, USA, is an integral part of Downingtown Area Robotics, a non-profit organization dedicated to running all levels of FIRST robotics. They significantly impact hundreds of students, fostering a passion for science, technology, engineering, and mathematics.

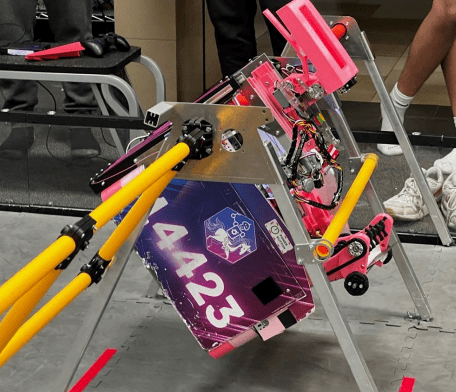

The RoboCorns actively participate in FIRST robotics, specifically the FIRST Tech Challenge. In this competition, teams consisting of up to 15 students collaborate to design and build robots with maximum dimensions of 18 x 18 x 18 inches. These robots are tasked with performing various challenges to earn points on a 12-foot by 12-foot field of foam tiles. The tasks range from placing plastic cones on tall poles and hanging the robot from a truss to arranging game pieces in specific patterns. The game changes annually, necessitating continuous innovation.

In the 2023-2024 season, named Centerstage, 7,681 teams registered to compete internationally. From Pennsylvania, four teams qualified for the FTC World Championship in Houston, Texas, USA. At this prestigious event, 231 of the world’s top teams competed, and the RoboCorns proudly emerged as a Control Award finalist.

Innovation and Challenges in Robot Design

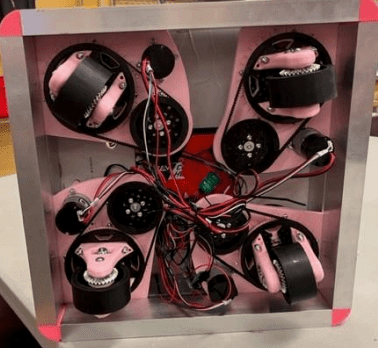

The RoboCorns undertook the ambitious project of designing a custom drivetrain known as Swerve, one of the first of its kind in the FIRST Tech Challenge (FTC). A Swerve drivetrain enables each wheel to be controlled and moved independently, necessitating the design of multiple custom parts. The team encountered a significant challenge with the mounting plate for each wheel assembly, which was made from extruded PLA+. They doubted that a 1/4-inch thick PLA+ plate could withstand the forces experienced during a match.

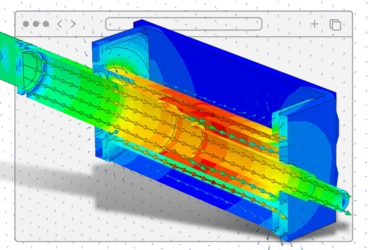

To address this issue, the RoboCorns integrated Computer-Aided Engineering (CAE) into their development process. This allowed them to predict the behavior of their plastic and metal components, determining whether a part would be durable or likely to fail due to breakage or deformation. Before adopting CAE and SimScale, they could not confidently assess the strength of their custom parts, often leading to the failure of 3D-printed components due to suboptimal design.

The team chose SimScale because it seamlessly integrated with their documents in OnShape, facilitating the easy import of parts into workspaces. Additionally, being browser-based, SimScale allowed for effortless collaboration across multiple devices without the need to download software.

“As high school students, we lacked CAE and FEA software experience. By using SimScale’s guides and intuitive simulation setup, we quickly became comfortable with setting up simulations for our parts and pulling graphed data from the simulations.”

– Team RoboCorns

Results From RoboCorns’ SimScale Simulations

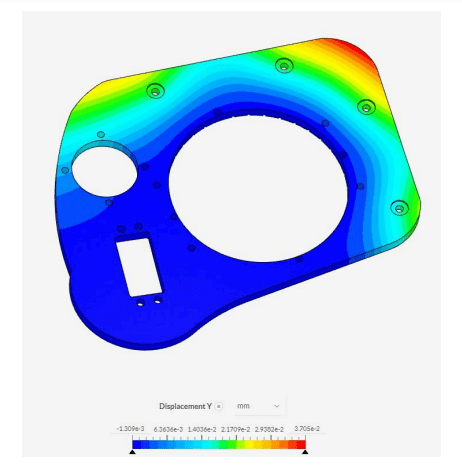

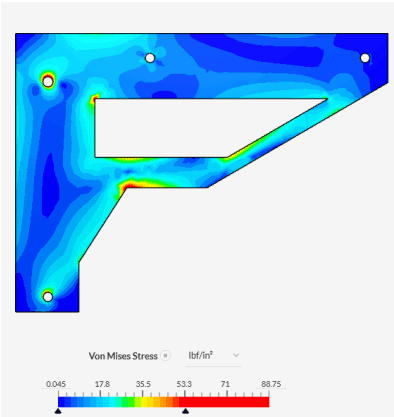

The RoboCorns’ simulations performed well, providing meaningful data that facilitated design improvements. Over the course of their competitive season, they conducted a total of six simulations to analyze the custom parts they believed were at risk of failure. These simulations were efficient, never exceeding three minutes or 0.1 core hours. The primary results they focused on were Von Mises Stress and displacement, which were crucial in determining whether their 3D-printed parts could withstand competition forces.

They examined the displacement of each part along each axis and assessed the stress distribution throughout the model to identify areas needing additional support. This information guided them in strengthening high-stress areas in their designs.

“Because of the predictability that SimScale’s CAE provides us, our number of prototypes has decreased drastically. We plan to keep using SimScale to test all our new designs.”

– Team RoboCorns

SimScale enabled the project to run smoothly and efficiently, reducing the number of prototypes needed and preventing part breakage after manufacturing. Additionally, SimScale helped the team acquire basic CAE and FEA skills, significantly enhancing their robot design throughout the season.

“SimScale is an amazing software for teams that work across multiple devices. SimScale allows for seamless integration with a cloud-based workflow and creates excellent visualization of results. SimScale has helped our team reach the next level in our education and gave us a competitive advantage. We are very grateful for SimScale for being a part of our journey to the FTC World Championship and helping us win an award.”

– Team RoboCorns

If your team seeks academic sponsorship for optimizing your robotics design and performance for any type of student competition, make sure to check out our Academic Plan for students who are joining design competitions.