Orion Racing India, a team of dedicated engineering students from K J Somaiya College of Engineering in Mumbai, has consistently demonstrated excellence in designing, building, and racing high-performance Formula Student vehicles. Driven by a shared vision, the team has successfully combined technical expertise, innovation, and teamwork to achieve remarkable milestones in motorsport.

As four-time champions of the prestigious Formula Bharat competition, Orion Racing India has set a benchmark for performance and perseverance. The team further cemented its legacy by becoming the first Indian team to complete endurance events on an international stage in both combustion and electric vehicle categories. This groundbreaking achievement underscores their commitment to pushing boundaries and advancing engineering excellence on the global stage.

Design Challenges

Faced with the limitations of traditional prototyping methods, the team sought a more efficient approach to refining their designs. Incorporating computer-aided engineering (CAE) allowed them to simulate airflow around their vehicles and make data-driven adjustments swiftly. This transition enabled faster innovation and more effective design optimization, elevating their overall performance.

After evaluating multiple CAE solutions, Orion Racing India selected SimScale because it offered several key advantages that aligned perfectly with their needs. The platform’s cloud-based accessibility facilitated seamless collaboration among team members, regardless of location. Its user-friendly interface, coupled with specialized Formula Student and Formula SAE workshops, strengthened the team’s understanding of computational fluid dynamics (CFD) fundamentals. Additionally, SimScale’s responsive and knowledgeable support team provided invaluable assistance, ensuring smooth progress even during challenging simulations.

How SimScale Simulations Led to Success

Through the adoption of SimScale, Orion Racing India has transformed its design process, driving innovation and efficiency in the competitive world of motorsport.

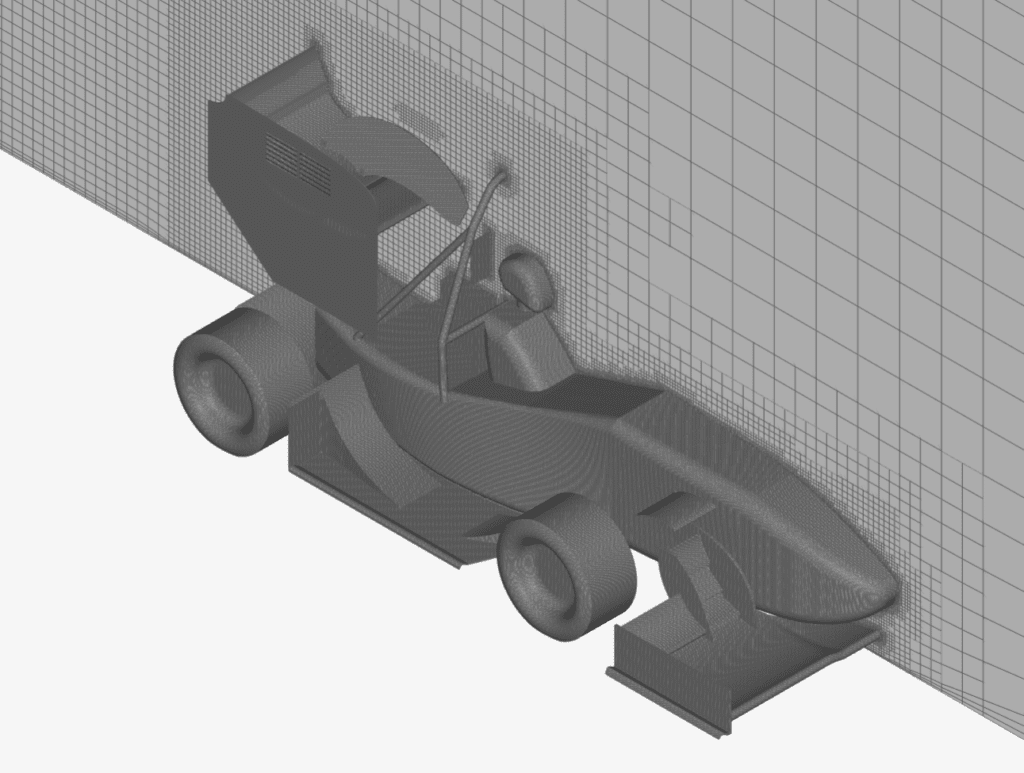

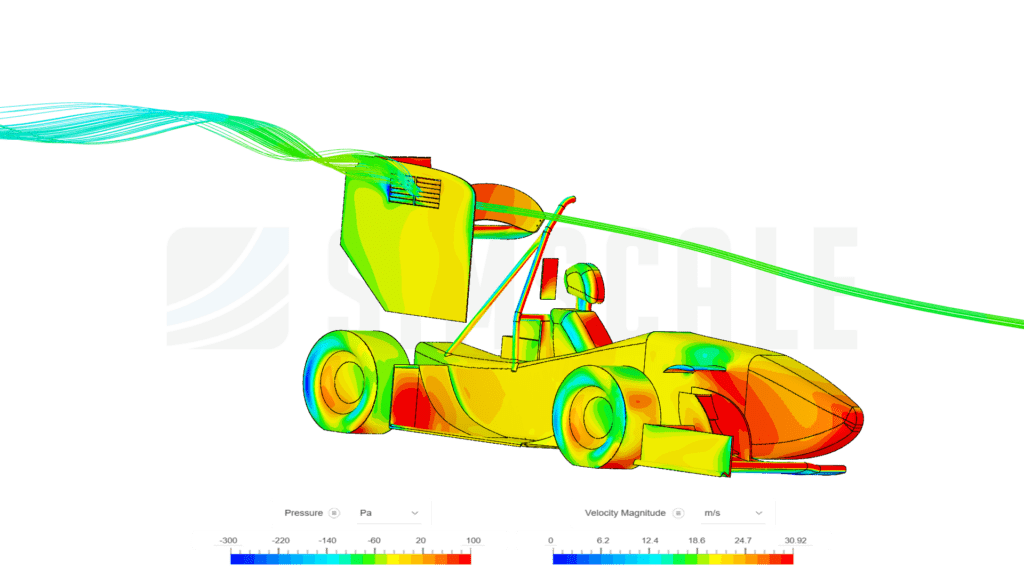

Orion Racing India utilized advanced simulation techniques to refine the aerodynamic design of their half-car model. The design was meshed using SimScale’s Hex-Dominant Parametric Meshing Algorithm, ensuring precise modeling of walls and wake regions critical for aerodynamic analysis.

“The accessibility and streamlined workflow, combined with its reliability has made SimScale an essential tool to our development process. Ability to run parallel simulations and remote access to the tool are game-changers.”

– Ankon Mukherjee, Aerodynamics Engineer

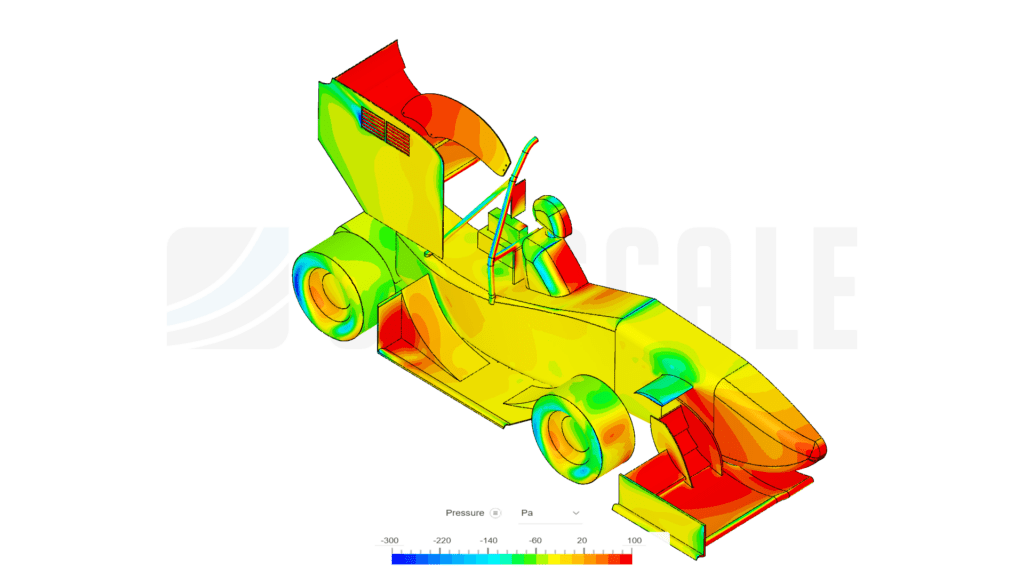

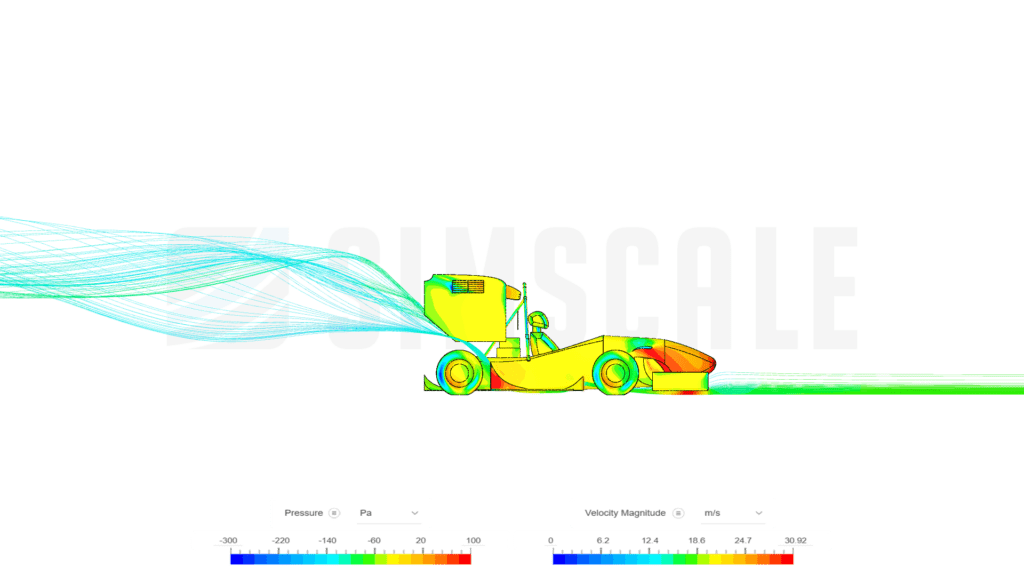

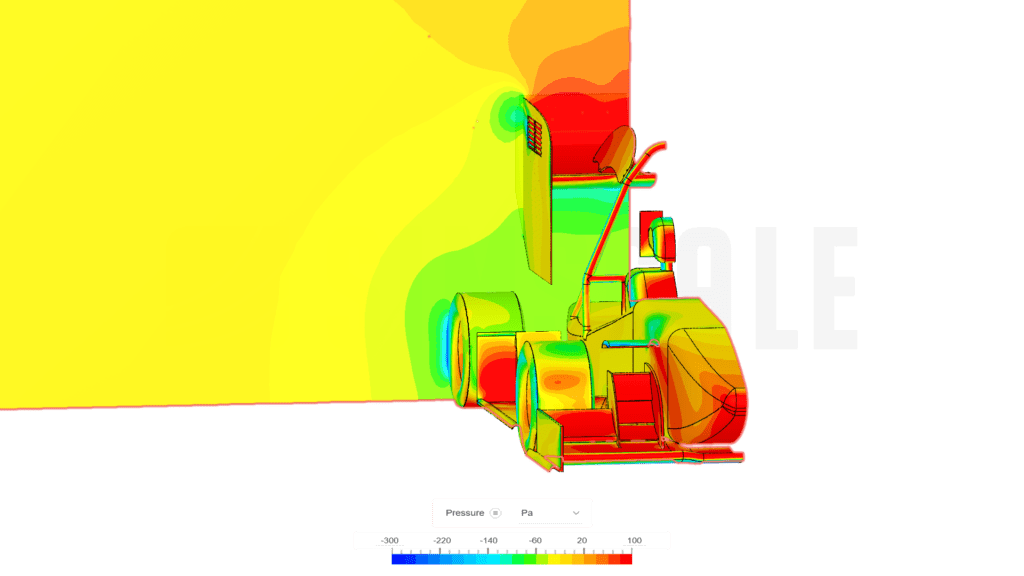

To simulate airflow, the team employed an incompressible flow analysis with the k-omega SST turbulence model, chosen for its reliable performance in handling adverse pressure gradients and separating flows. The simulation setup included a velocity inlet of 16 m/s, with slip conditions applied to the ceiling and outboard wall, while the car’s centerline was assigned a symmetry condition. The ground was modeled as a moving wall at -16 m/s, replicating real-world conditions.

Since integrating SimScale into the aerodynamic design process of their Formula Student race car following the 2017 season, Orion Racing India has made it an essential component of their workflow. More recently, the team expanded their use of SimScale’s capabilities to include thermal simulations for critical components such as the radiator and accumulator, further enhancing their design process.

“The decision to switch to SimScale for our thermal simulations greatly improved our efficiency due to its user friendly interface and the ability to run multiple simulations at once”

– Aaron Crasto, Cooling Engineer

The car’s body was simulated using a no-slip boundary condition, with the wheels modeled as rotating bodies to capture wake effects accurately. To ensure comprehensive analysis, the team simulated the car in various dynamic scenarios, including yaw, pitch, and roll. This detailed approach enabled Orion Racing India to achieve high accuracy and performance optimization in their aerodynamic designs, further enhancing their competitiveness in motorsport.

Orion Racing India conducted over 300 simulations throughout their design process to optimize their final aerodynamic and cooling packages. Leveraging SimScale’s extensive suite of post-processing features, the team aligned simulation data with physical testing benchmarks, including tuft testing, to validate and enhance confidence in their virtual analyses.

Each simulation run required approximately 1.5 to 2 hours, with a total runtime of around 5 hours when meshing was included, utilizing 16 cores for both operations. To achieve high-quality meshing, the team employed the hex-dominant parametric meshing algorithm, resulting in a final mesh with approximately 8.5 million nodes. Refinement levels were tailored to suit the design complexity, with most of the body refined at level 6 and intricate geometries at level 7 to ensure precise results.

SimScale has become an indispensable tool in Orion Racing India’s design process. Simulation results from SimScale are utilized at every stage of development. Aerodynamic data guides the design of critical components such as wings and diffusers, while thermal simulations ensure the cooling systems operate at peak efficiency. By iteratively refining their designs based on these insights, Orion Racing India achieves a finely tuned balance of speed, reliability, and efficiency in their final vehicle.

This streamlined, data-driven approach empowers the team to push boundaries and deliver high-performance solutions in the competitive world of motorsport.

“The results we obtained from SimScale have been very close to the actual values we obtained during the running of the car. We are very pleased by the accuracy of the simulations”

– Abhishek Dubey, Battery Pack Engineer