Robert Boz founded his company eight years ago in Australia, with an initial focus on the optical industry. Today, Meccanica is a joint venture with Marco Engineering, which has 50 years of experience in engineering. This collaboration merges the unique strengths of each entity to provide a unified solution partner with capabilities in engineering design and analysis, multiphysics simulation, testing and validation, and more.

With ongoing projects for the commercial, defense, scientific, and aerospace industries, the joint venture has a philosophy of continuous improvement in research and development, prototyping, product development and high-value manufacturing processes.

No stranger to engineering simulation, Robert noticed the shortcomings of on-premises software and began to look for alternatives. The biggest issue for him was the limitation of computing power. The local workstation becomes basically useless during a simulation run, which can take up to 16 hours per calculation.

CAD and CAE in the Cloud with Onshape and SimScale

In his search for an alternative for simulation, Robert discovered Onshape and quickly adopted it as his preferred CAD design tool. The collaboration between his team and the clients went smoothly, which built his preference for cloud-based solutions.

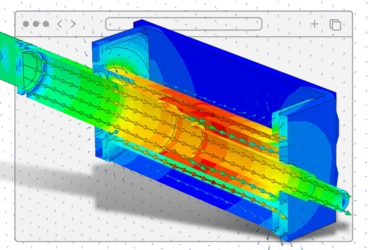

Because Onshape and SimScale not only have a partnership but also an integration called Connector App, there was only one step from Onshape giving SimScale a try. The Connector App enables users to access and operate the entire design cycle in the cloud, from CAD creation to CFD or FEA simulation.

FEA and CFD Simulations

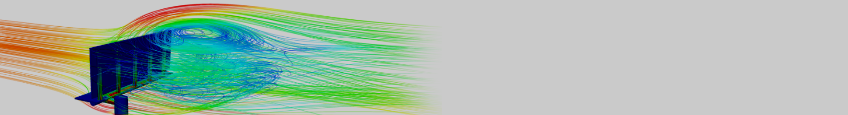

Meccanica’s expertise and projects are diverse, just like the simulations that the engineers had to perform. The access to all of SimScale’s features was definitely a change from traditional software, which often requires paying for different licenses depending on your needs. The team performed structural analyses and fluid dynamics simulations, and the integration of high-end numerical tools allowed him to move away from hand calculations.

The simulation provided detailed information about the system’s performance while highlighting areas in the design which might need dedicated investigation in order to optimize the whole system.

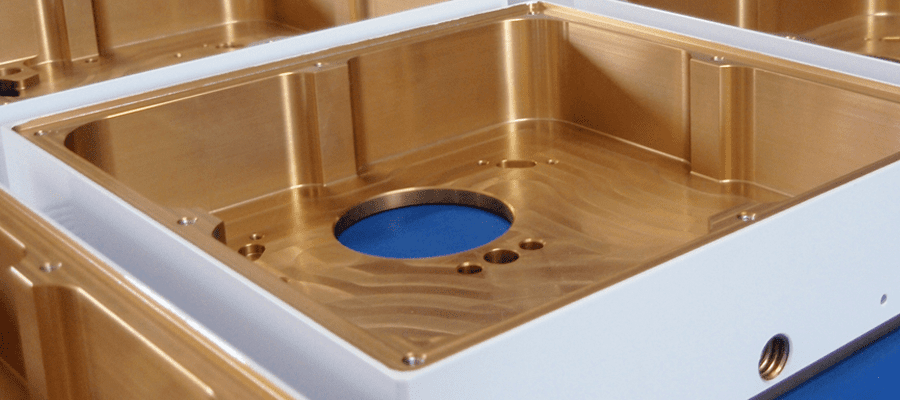

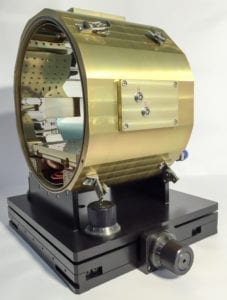

Stress Analysis of a Vacuum Chamber

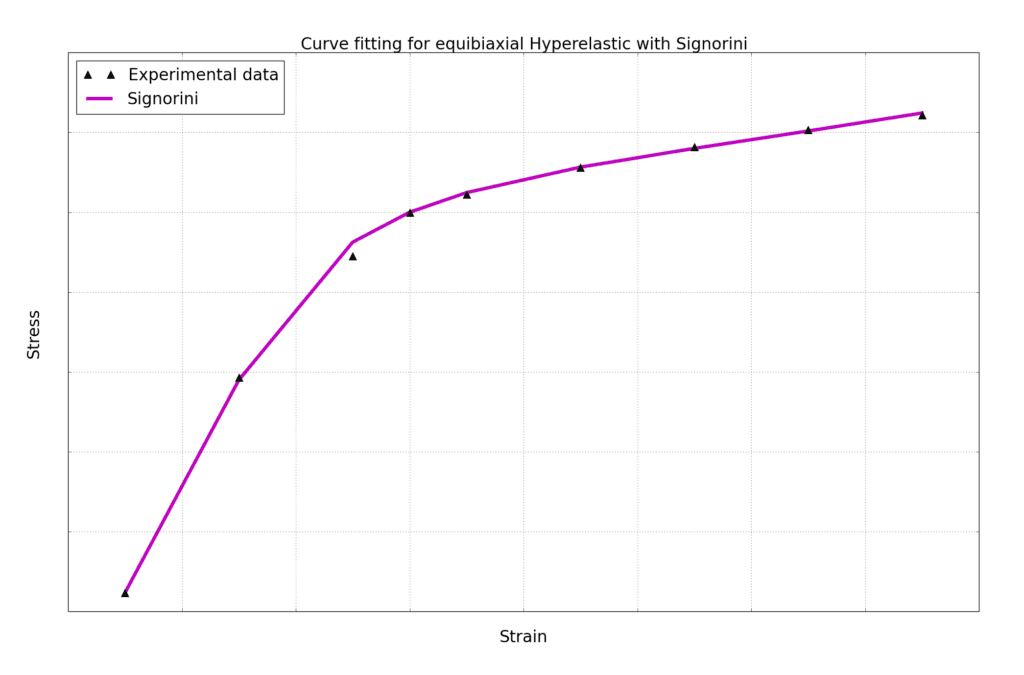

An example of analysis that Meccanica worked on using SimScale was the stress analysis of a cryogenic vacuum vessel. The task aimed to present the behavior of the assembly exposed to atmospheric pressure while keeping the inside of the part in a vacuum. Since no significant deformations were expected, the static finite element analysis type was selected. The nonlinearities of the problem were limited to physical contacts. Further modeling improvements were achieved by removing hyperelastic o-ring gaskets.

In order to acquire the best leverage of time and accuracy, the geometry was first tested on a coarse mesh. With this approach, the simulation setup could be tested, and modifications of the settings could be quickly applied. After the coarse mesh produced a reasonable and stable simulation, the geometry was discretized with much more precision. As a result, the obtained results were accurate and reliable.

The results have demonstrated the capability of the platform to tackle complex systems of vacuum vessels. Data analysis has shown the displacements of the top and bottom plates with respect to the casing. Most importantly, they have demonstrated that contacts are engaged in limited areas, which might result in poor closing. A comparison of the results of simulations with and without gaskets have shown that, as assumed, the part had little effect on the precision of simulation.

The performed analysis provided valuable insights into the behavior of the cryogenic vacuum chamber and was a great starting point for further, more detailed investigation.

If you want to give SimScale a try, you can create a free community account.

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!