In any building design, ventilation is a critical component in ensuring thermal and human comfort. Determining how airflow moves within a home or office dictates how temperature is regulated, how smells from cooking or other sources permeate, and even effects the health of inhabitants by preventing air pollutants. The key to proper ventilation, whether it is naturally or mechanically maneuvered, is by allowing an uninterrupted airflow to mitigate negative implications of stagnant air. Yet, how can you be sure what type of ventilation a built structure needs, or how to control the velocity of the airflow without restraining it? In this article, we will explain how to use online simulation to answer these queries, and how to create and improve your ventilation system design.

Why is Ventilation System Design Important?

Aside from assuring human climate comfort, the importance of ventilation essentially comes down to controlling moisture in the air, supplying fresh air, and being able to manage these factors within a given space. Without adequate airflow, wood rot and drywall can become a very real problem to homeowners and business owners alike, mold can begin to cause detrimental effects to health, and structural integrity can begin to falter.

How ventilation is designed within a building is also important for legal health and safety factors. For example, engineers need to establish in the building planning process how fire and smoke would spread within a space, and how to mitigate dangerous outcomes. These complications are often exasperated by failure to consider seasonal airflow changes alongside the proper implementation of a ventilation system.

Natural Ventilation vs. Mechanical Ventilation

When considering a ventilation system design, options generally fall into two overarching categories—mechanical ventilation or natural ventilation.

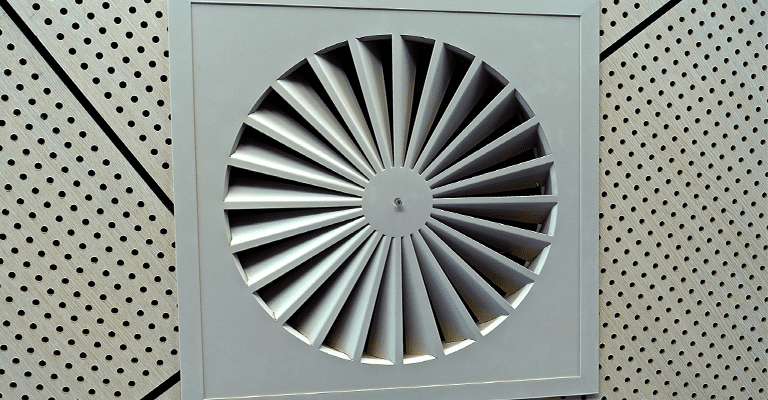

Mechanical Ventilation In HVAC

Mechanical, or forced/induced ventilation for HVAC ventilation system design uses man-made devices to create the effect of natural ventilation to a greater extent. Compared to natural ventilation, this type of airflow control is preferred in spaces that have to deal with more extreme external factors like humidity, and therefore require air conditioning to maintain thermal comfort. mechanical ventilation simulation is generally needed to ensure the required of comfort can be maintained.

Using mechanical ventilation simulations, you can even design ways to control contamination, odors, and more, beyond natural ventilation capabilities. Exhaust fans are a great example of the capabilities of forced ventilation.

Shortfalls of Mechanical Ventilation

The downside of HVAC mechanical ventilation systems is the energy used. Although you can install heat recovery ventilators (HRVs) to recover lost energy, an electrical ventilation system will never be as energy efficient as a natural system. Along with this more obvious drawback, forced ventilation can depressurize a space leading to further issues with natural vent applications, and even hot water heaters and furnaces that rely on positive pressure to operate. This negative pressure can even be dangerous for inhabitants of a space, as it can pull gasses into a living environment that can prove to be toxic in large quantities. Once again, this calls for mechanical ventilation simulation to ensure safety requirements are met.

Natural Ventilation in HVAC

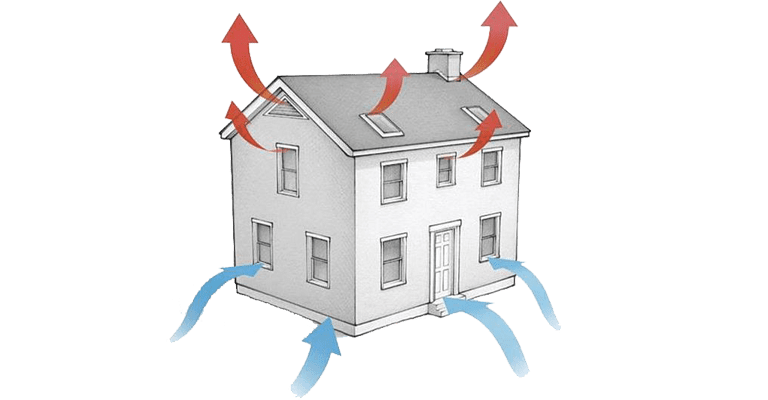

Natural ventilation supplies and extracts air to and from indoor areas through organic airflow. This phenomenon is possible through harnessing the power of air pressure differences from natural forces defined by two varieties: buoyancy-driven and wind-driven. Buoyancy-driven ventilation is a result of temperature differences between the internal and external space of the structure. like mechanical ventilation simulations, this natural airflow can also be simulated.

Wind-driven ventilation, on the other hand, arises from pressures created by wind force around a building based on aerodynamic properties, as well as openings that allow airflow through the given space.

Shortfalls of Natural Ventilation

Although more energy efficient and safe, natural ventilation can be unreliable in removing and introducing fresh air to an indoor space due to the nature of the natural forces it replies upon. The uncertain driving forces of natural ventilation alongside difficulties in overall control of airflow can deem natural ventilation not efficient enough in some cases due to certain climates.

Stack Effect in Natural Ventilation

One commonplace occurrence arising from natural ventilation that must be considered is stack effect or chimney effect. This airflow results from the aforementioned air buoyancy-driven natural force that emerges from different air pressure, temperature, and density levels between corresponding internal and external environments. The contributing variables that create this physical effect are the thermal difference along with the height of the given structure. Airflow through a chimney is a clear example of stack effect due to its inclusion of the two chief variables at play; height and temperature difference. The following case study explores this concept in depth.

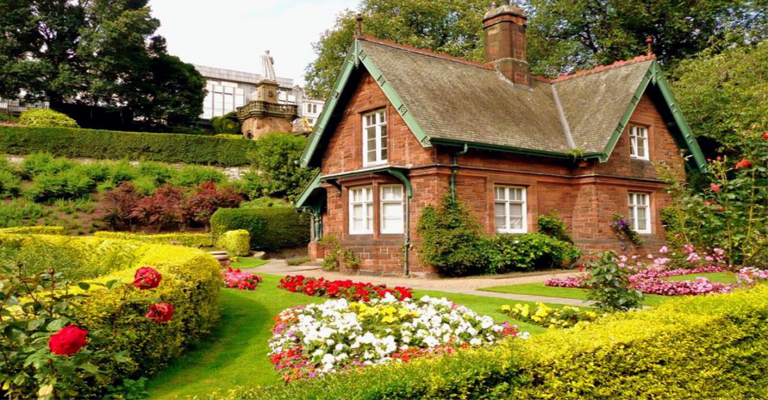

Case Study: Natural Ventilation in an English Cottage for Summer and Winter Conditions

As we’ve learned already, stack effect (or chimney effect) is the specific behavior of air caused by temperature and air density differences. To visualize this phenomenon, container-like appendages to a structure such as flue-gas stacks or chimneys best facilitate this airflow behavior. Along with ventilation and air filtration, it can also aid fireplace plumes and contained smoke propagation within a fireplace. This project from SimScale demonstrates the effect within a home, along with the seasonal differences in air pressure.

What Was the End Goal of the Simulation?

The end of the simulation is to evaluate the direct and reverse effects of stack effect within a building—in this case, a country cottage—and understand where ventilation system design can come into play. Direct stack effect is where the temperature difference generates a buoyancy effect that drives the flow inside the house at the low level and expels it at the top level. This occurs when the external climate is cold, therefore it is most prevalent in the winter season. The reverse of this is experienced in opposite climate conditions, where the effect is usually weaker due to lower temperature difference.

The simulation aims to understand the degrees to which the buoyancy forces provoking the stack effect (height and temperature gradients) can be manipulated. Along with this, the ultimate goal of the simulation is to detect ventilation patterns due to temperature differences as well as become familiar with convective heat transfer in SimScale, and how the platform can help designing ventilation systems.

Ventilation Simulation Setup

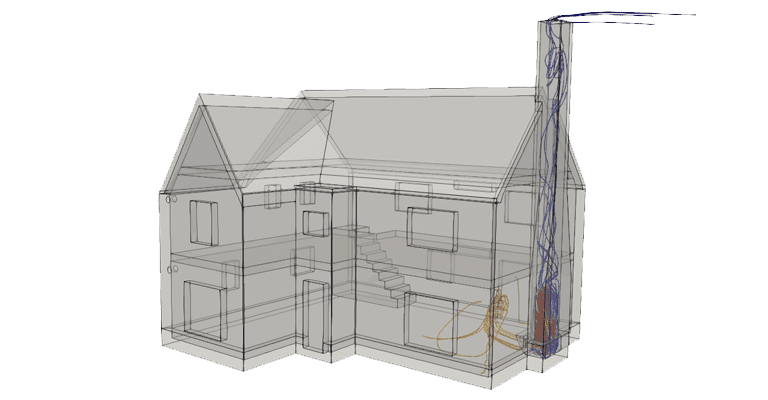

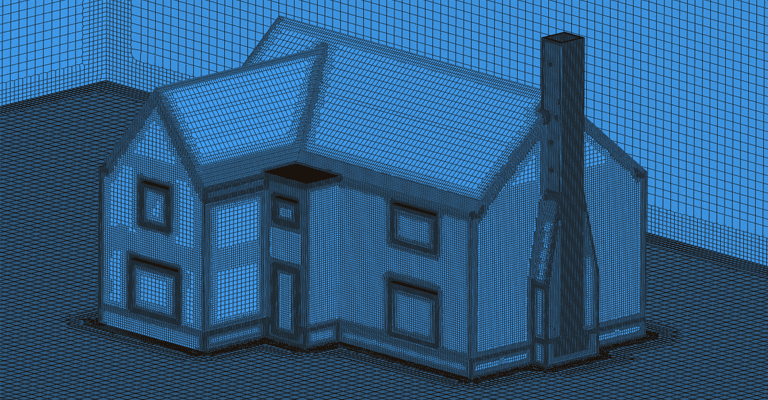

A simplified CAD model of an old English cottage was created with some interesting elements for the simulation including two floors, chimney, windows, ventilation above the windows, and air conditioning units. The addition of air conditioning units in the project also allows for mechanical ventilation simulation.

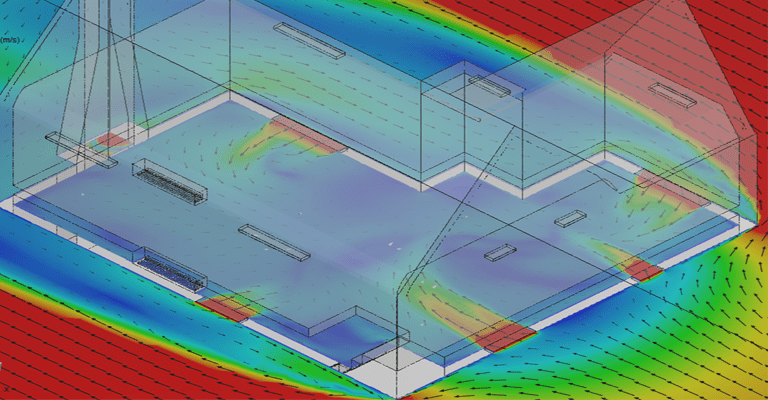

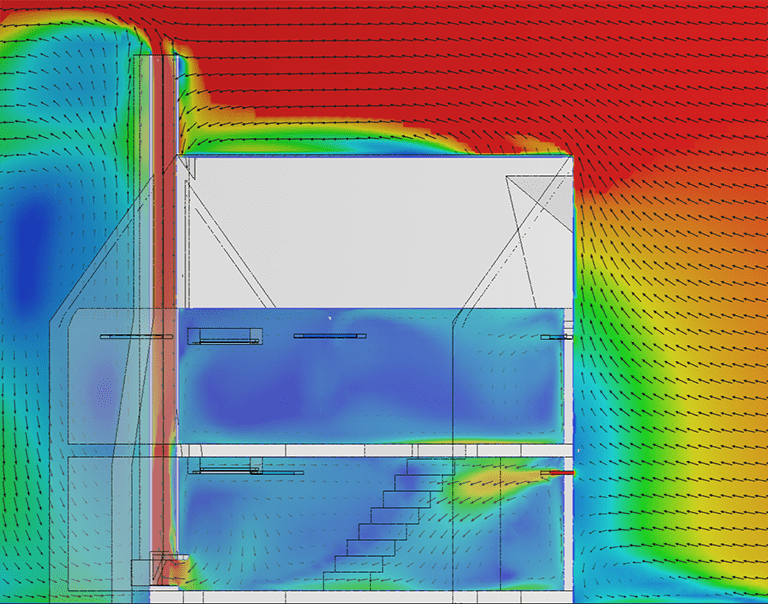

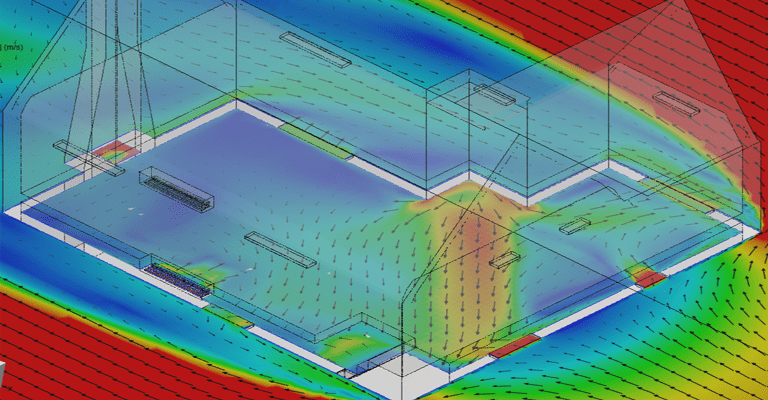

Both internal and external flow were simulated within an enclosure domain to better visualize the air entering and exiting the cottage. A convective heat transfer analysis using compressible turbulence flow was then carried out for both external conditions, using summer and winter average temperatures. Along with this, different cooling and heating sources were tested within the house.

Seasonal Stack Ventilation Results

The results of the simulation provide insightful validations and powerful visualizations of the change of airflow in the two contrasting climates, taking into account the different floor levels, artificial ventilation producers in the form of AC units, windows, and chimney. The project shows how natural and of mechanical ventilation simulation is possible with CFD from SimScale.

The image above shows the resulting velocity plots of the project from the winter season simulation. As you can see, air enters the room through the ventilation ducts, and higher convection heat transfer occurs on the ground floor of the cottage. As cool air enters the house from the different entry points, there is a smooth transition into room temperature.

The simulation results show high flow acceleration through the chimney due to large temperature gradient (peaks at 10 m/s).

In the contrasting summer simulation runs, air exists through ventilation ducts as the temperature difference has flipped from the external and internal environments. Air is shown to be entering from a frontal artificial ventilation source which creates an area of recirculation as well as a heat source. These findings could be concerning to a designer, and make them rethink their ventilation system design to eliminate these flaws.

Watch the recording of our recent webinar on the same topic by filling out a short form here, and check out our published slide deck for more information.