Designers of fans and other turbomachinery need to perform both CFD and FEA simulations to test their products early in the design stage, long before creating a physical prototype.

At SimScale, we have customers focused on ensuring the performance, durability, and energy efficiency of their fan designs. To achieve their goals, they use simulation to calculate flow rates, static pressure, total pressure, static efficiency, total efficiency, peak total efficiency, forces and moments acting on the fans, and more. In addition, analyzing and optimizing fan vibrations and conducting structural analyses on the foils, brackets, and structural mounts to ensure structural reliability are common projects.

Among these customers is the engineering office Dr. Heiser (based in Mannheim, Germany), which provides services for the design and analysis of aerodynamic applications such as fans and other turbomachinery, but also wind tunnels and fire safety.

Download this case study for free to learn how the SimScale CFD platform was used to investigate a ducting system and optimize its performance.

Radial Fan Design Increasing the Volume Flux through a Radial Fan

The engineers from Dr. Heiser office planned to make several design changes to increase the volume flux through a fan. This had to be done while respecting the limits regarding the power consumption of the fan and the minimum pressure increase that the fan should generate. Different design changes have been developed to increase the volume flux while respecting the mentioned limits.

The SimScale platform enabled the engineers to predict the performance characteristics of the new designs by analyzing the CAD models.

The expensive and time-consuming manufacturing of a prototype was thereby postponed by the engineering team to a phase where a mature design version would exist.

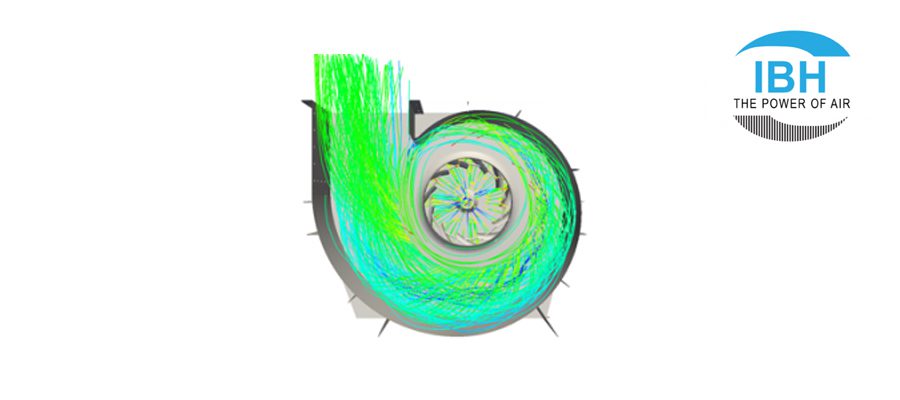

CFD Analysis of the Radial Fan Design

The first step was uploading the CAD model of the new design onto the SimScale platform and set up a fluid flow simulation.

The actual computation was then carried out on an 8-core machine since the rotating domain in the middle and the relatively large number of cells needed considerable computing power. Due to the availability of large computational power of SimScale, the results could be analyzed after only one hour. Both the integrated post-processing environment of SimScale and the local software ParaView were used to visualize and analyze the result fields.

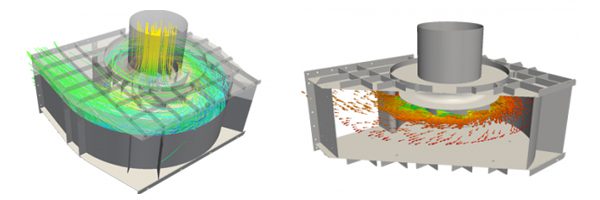

Simulation Results

The most important results of the CFD analysis were the pressure increase and the power consumption of the new radial fan design.

The figures show the pressure field in the middle section of the fan housing (red = high pressure, green = low pressure).

One can clearly see the increasing pressure across the rotating fan blades.

The simulation showed that the design changes lead to the desired higher volume flux while respecting the other performance limits with regard to the power consumption as well as the pressure increase.

Based on the data, the performance of the fan could be predicted just by using the CAD model and the SimScale simulation platform.

This enabled the Dr. Heiser team to make informed design decisions very early on in the development phase and postpone the manufacturing of a physical prototype to a later design phase. This, in turn, decreased the risk of late design changes. At the same time, it reduced the costs and development time.

This article was based on the original Dr. Heiser case study which can be found on the website.

Want to learn more about fan simulation? Discover this page: Simulation for Industrial and Commercial Fans or download our free white paper: How to Use CFD to Improve Energy Efficiency of Fans for Air Handling Units.