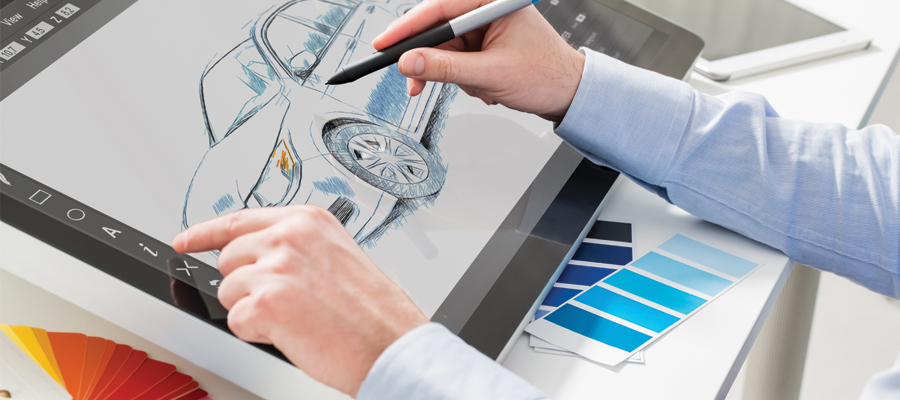

From sketch to the end result, product creation is a journey. The product design world is a mix of vision and pragmatism, combined with creativity, technical skills, and entrepreneurship.

Industrial product design often relates to the discrete manufacturing of any product, from large mass electronics and domestic goods to very specific appliances and industrial machinery. Regardless of the industry, product designers should be involved in the business process and customer feedback.

Product designers need to know how to combine creativity with logical vision and this requires extensive knowledge in model making, good technical skills, computer-aided design (CAD) basics, and also project management skills.

Main Responsibilities of Product Designers

Product designers usually specialize in a specific product type. It is essential to ensure that the result of their work is easy to use, qualitative, cost-effective to produce, and attractive to the users. Product designers need to fully understand their clients’ desires and budgetary requirements in order to satisfy those needs.

Depending on the nature of the project, product designers’ main tasks generally involve:

- Creating the product brief and investigating what the client wants

- Scrutinizing how existing products work

- Visualizing ideas through initial sketches and outline plans

- Choosing the necessary materials and resources

- Using computer design software to create detailed product blueprints

- Making prototype samples or working models

- Testing designs for functionality

- Refining the designs to solve any problems or faults

In all stages of product realization, product designers need to collaborate with engineers, concept modelers, engineering simulation and testing specialists, and manufacturing engineers. They can be a part of a manufacturing in-house design team working on a new product launch, freelancers, or consultancy firms.

5 Essential Things Product Designers Should Know

Early in the product development process, product designers should consider these five tips when starting the product design phase of the product:

1. Collaborate with a Heterogeneous Team with Different Goals

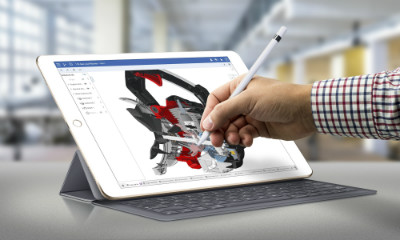

Engineers and product designers have different objectives for a project outcome. Engineers are interested in pragmatic goals of product development such as product reliability, quality, dimensional details, materials supply, and manufacturing processes. Product designers are more focused on the creative aspects such as design features, user experience, and competitive alternatives. It is important for all team members to work together and achieve the goals of the project. Allowing collaboration between team members, cloud-based CAD and CAE solutions offer a platform for the team to work anywhere, anytime, and from any device.

2. Simple Thinking

Product designers should not complicate development processes. Acting as essential creation pivots in the product development process, a product designer’s role is to ensure a perfect fit between product functionality and design. Any new product should be user-friendly and simple.

Using a CAD software, delivered as SaaS (Software as a Service), like Onshape, product managers can collaborate in real time with not only engineering and manufacturing team members but with partners and clients as well. This way, they can control how the simplicity of the design concept better fits the final goals of the new product, right from the outset.

3. Look at Existing Products

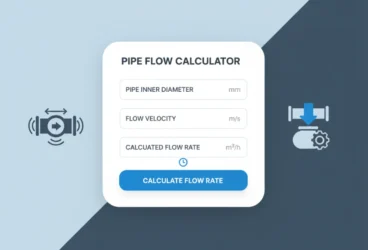

Customers need better products that are practical. Nobody needs to reinvent the wheel for this purpose. Before starting with the design concept, product designers should investigate existing products reviews, competitors’ product features, and functionality. Using CAD and CAE software in the cloud, product designers can ensure real-time optimization of the existing product, working on the same digital models. Partners and clients can preview the prototypes digital image on any mobile device, and designers can improve the product design, dimensions or material, starting from the previous models.

4. Proper Testing

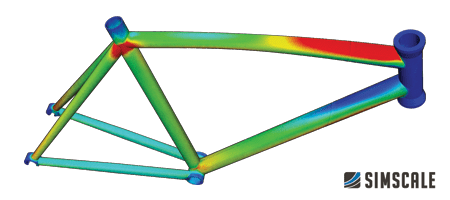

Product designers and engineering teams should benchmark new products, evaluating how new features and functionality can be implemented into the product design. Before manufacturing, product testing is required. Experienced product designers prefer to do virtual testing through CAE and then create the physical prototypes.

5. Have Trust in Simulation

Engineering simulation is not an alternative to physical prototyping but rather a complementary step offering a cost-effective way to test designs through numerical analyses, making the necessary changes and improving the design before creating costly physical prototypes.

By providing a new way of performing engineering simulation, web-based CAE platforms like SimScale offer a better and more cost-effective solution for virtual testing, that only requires a normal PC or laptop and Internet connection.

Read about the benefits of web-based simulation compared to classical on-premise engineering solutions in this article: 10 Reasons Why Cloud-Based CAE is the Better Option.

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!