As the automotive industry strives towards ever greater innovation and efficiency, engineering leaders across the sector are increasingly adopting simulation-driven design practices, modernizing their engineering processes while maintaining the integrity of established workflows. They understand the huge ‘innovation unlock’ opportunity represented by earlier and broader use of simulation in design exploration, yet many still face the voicing of the same concerns around compatibility, workflow integration, and security. These are often heard when looking to introduce new CAE simulation solutions and practices into a business. In order to build consensus and support for their change programs, it’s important for engineering leaders to recognize the source of such objections and take material steps to address them.

This SimScale guide highlights the most common objections seen when leaders make the decision to transition to cloud-native simulation and are based on insights gleaned from over 100 successful implementation projects with major automotive suppliers. By examining how other forward-thinking automotive supplier leaders have overcome such challenges, we hope to arm you with the knowledge needed to build consensus for change, allowing you to lead your team toward more efficient, innovative, and agile design processes.

1. “It won’t work within our existing simulation tool landscape.”

Compatibility is often one of the first concerns raised when considering new simulation platforms. Many engineering teams worry about disrupting established workflows or needing to overhaul their current tool landscape. However, cloud-native platforms like SimScale are designed with interoperability as a core feature.

SimScale’s architecture supports industry-standard file formats, including STEP, IGES, and STL, ensuring seamless integration with commonly used CAD software such as CATIA, Siemens NX, and SolidWorks. This allows teams to continue using their existing design tools without friction, enabling a smooth transition to cloud-based simulation without costly retooling or data migration.

The real risk lies in holding onto outdated methods due to the fear of change. By adopting SimScale, forward-looking automotive suppliers have been able to enhance their simulation capabilities without disrupting their current workflows, leading to faster product iterations and reduced lead times.

SimScale’s extensive support resources, including detailed documentation and dedicated technical assistance, further ensure that integration is smooth and efficient, minimizing operational friction. Suppliers who have made the transition to cloud-native simulation have reported improvements in project delivery times and increased innovation cycles—results that make it clear that concerns about compatibility can be confidently addressed.

For more information about SimScale’s integrations and proven workflows, check out our Integrations & Partners page.

2. “We don’t really believe in designers simulating.”

Traditionally, simulation has been the domain of specialized analysts, which made sense when tools were complex and simulations were time-consuming. However, as automotive suppliers face shorter design cycles and increasing demands for rapid innovation, relying solely on simulation experts creates bottlenecks.

Involving designers in the simulation process can alleviate the workload on simulation experts and reduce simulation lead times. Designers can simulate early in the design process, validating concepts and identifying potential issues without waiting for each iteration to pass through the simulation team.

SimScale’s platform allows simulation experts to develop guided simulation workflows, ensuring that designers work within robust, pre-defined parameters. This approach maintains quality control while enabling designers to run as many simulations as needed based on preset workflows that can be easily validated. The result is faster iterations, reduced bottlenecks, and a more collaborative design process.

Moreover, SimScale offers comprehensive training and support resources tailored to designers, ensuring they have the knowledge and tools necessary to leverage simulation effectively in their workflow.

By empowering designers to simulate within guided workflows, automotive suppliers can accelerate lead times and maintain high standards, all while driving innovation in an increasingly competitive market.

3. “We already do simulation.”

Many automotive suppliers already have simulation processes in place, but the question becomes: How does SimScale set itself apart in an industry where simulation is already the norm?

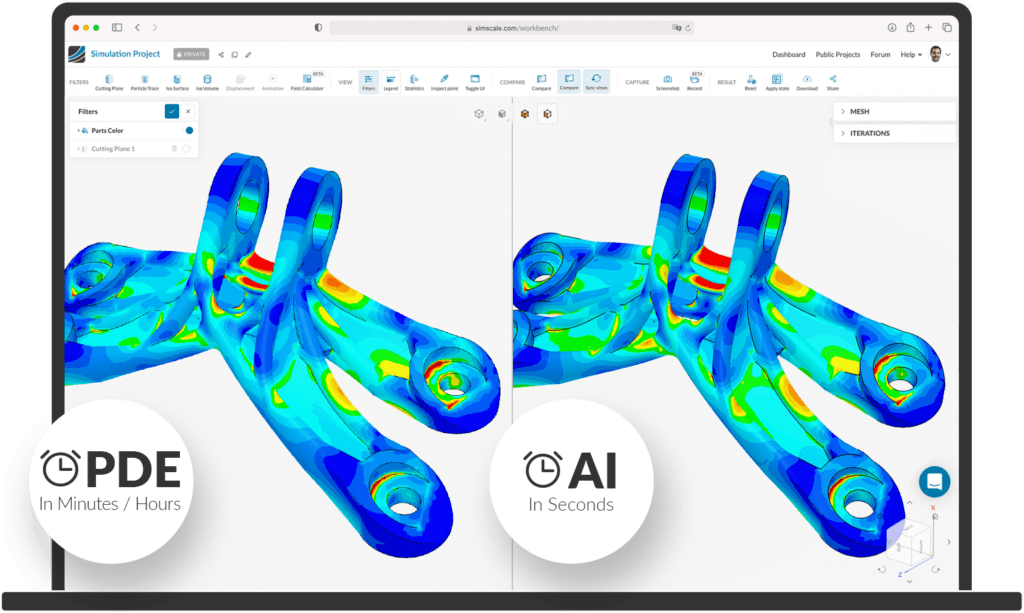

SimScale distinguishes itself with its cloud-native platform, which eliminates the need for costly hardware and infrastructure maintenance. By leveraging cloud computing, SimScale allows suppliers to dynamically scale their simulation capabilities to match workload demands without additional investment in hardware. This enterprise-wide simulation deployment ensures simulation experts can retain quality control while freeing teams from local hardware limitations. Whether it’s real-time analysis, AI-powered insights, or infinite scalability through parallel simulations, SimScale unlocks unprecedented design space exploration.

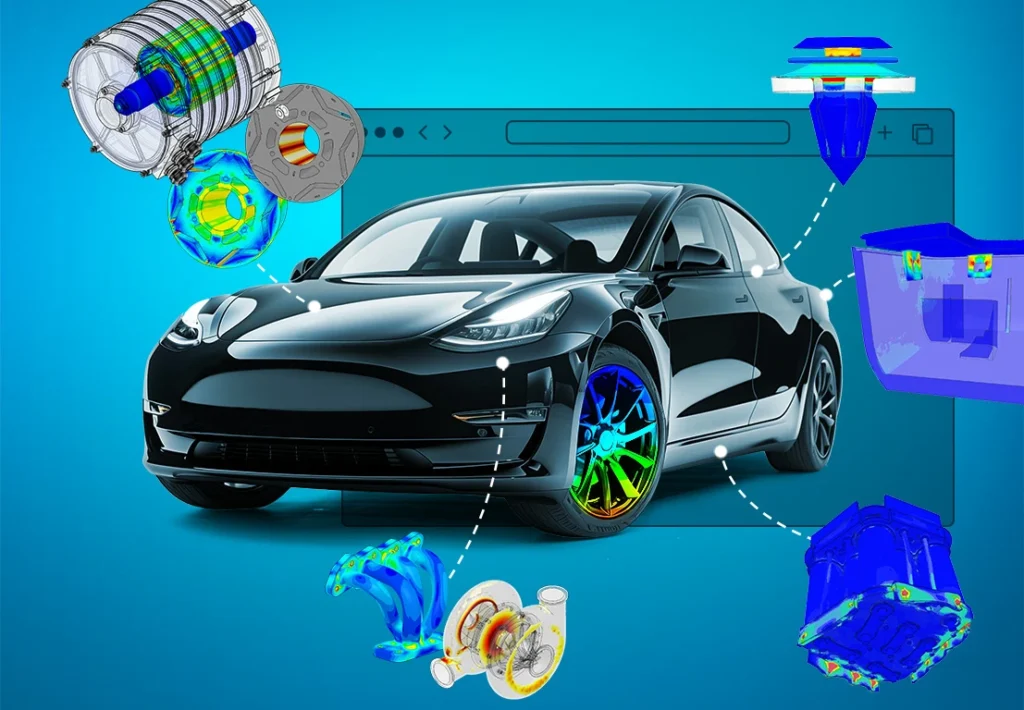

Beyond traditional finite element analysis (FEA) and computational fluid dynamics (CFD), SimScale offers a comprehensive range of simulation tools, including structural, thermal, fluid flow, electromagnetics, and multiphysics simulations. This broad capability addresses diverse engineering challenges in automotive design and manufacturing, enabling suppliers to push boundaries.

SimScale also fosters seamless collaboration. Its cloud-based environment allows teams to share data and insights effortlessly across departments and locations, accelerating decision-making and ensuring interdisciplinary alignment. By integrating cutting-edge technology with existing practices, SimScale enhances productivity, scales innovation, and enables automotive suppliers to stay ahead of the competition.

4. “The OEMs dictate which tool we need to use.”

OEM influence over tool selection in the automotive supply chain is a common concern, making many suppliers feel constrained by mandated tools. However, it’s important to view these requirements as opportunities to innovate and align more closely with OEM goals.

SimScale’s cloud-native platform enables seamless collaboration and data exchange between suppliers and OEMs, making it easier to integrate workflows and maintain clear communication. By adopting SimScale, suppliers demonstrate a commitment to innovation and efficiency, potentially strengthening their relationship with OEM partners.

With an extensive library of simulation templates and pre-configured workflows that adhere to industry best practices and standards, SimScale ensures compatibility with OEM requirements, whether for structural integrity analysis, aerodynamic optimization, or thermal management. This flexibility allows suppliers to meet or exceed OEM expectations while maintaining compliance.

Rather than seeing OEM mandates as limitations, SimScale positions suppliers to differentiate themselves through innovation and strategic alignment with OEM partners. This fosters mutual success in an increasingly competitive automotive industry.

5. “Cloud security issues are the problem.”

Security is often a major concern when adopting cloud-based simulation. However, SimScale has been specifically designed to address these concerns, ensuring that suppliers can adopt cloud-native solutions with confidence.

SimScale uses industry-leading encryption protocols to safeguard data both in transit and at rest, alongside strict access controls that ensure only authorized users can access sensitive information. Regular security audits and compliance with rigorous standards such as SOC 2 Type II further reinforce the platform’s commitment to protecting data integrity and confidentiality.

SimScale also meets industry-specific security requirements, giving automotive suppliers the peace of mind to innovate freely, knowing their data is secure. The platform’s security framework ensures that embracing cloud-based simulation does not come at the cost of data protection or regulatory compliance.

Suppliers can confidently transition to cloud simulation, reassured that SimScale’s proactive security measures protect their operations while enabling them to scale without risk.

For more information, visit SimScale’s security page or contact us. We can answer any questions you might have about data security.

Conclusion

While automotive suppliers’ objections regarding compatibility, efficacy, and security are understandable, SimScale offers compelling solutions backed by evidence and expertise. By addressing these concerns head-on and demonstrating the tangible benefits of cloud-native engineering simulation, SimScale enables automotive suppliers to embrace innovation, drive efficiency, and stay ahead in a rapidly evolving industry.