In motorsport, it’s necessary to optimize every component of the car. This includes the core parts (e.g., the engine), the aerodynamics, the tires, and so on. One of the most important parameters to improve is weight. In every category, there is a standard for minimum car weight, but optimizing it for the different components in order to distribute the weight within the car is crucial in improving the vehicle’s dynamics.

This procedure is present in its most extreme form in Formula One, where the engineers develop ground-breaking, innovative ideas to reduce the cars’ weight. Some of the solutions include manufacturing components with carbon fiber, or even having drivers follow strict diets to be as slim and lightweight as possible.

Understanding its importance, engineers began to lighten up the car components, primarily by using new materials such as titanium or magnesium, which have the same properties of resistance and hardness as the former ones, but less density. When they couldn’t improve the weight in this way, they started changing the components’ design, trying to use as little volume as possible. This method affects every component of the car, from the suspension arm to the support plate of the engine. It is even used on the steering wheel, the accelerator, and the brake pedal.

Some time ago, I worked on a simulation project that had the primary purpose of investigating how to reduce the weight of the brake pedal of a motorsport car by changing its design.

As most people know, there are different types of pedal systems, depending on position, distribution, and way of working. The most common systems are the pedal over the soil and the hanging pedal.

In a common car, the most common one is the hanging pedal. In motorsport, however, the pedal over the soil is preferred. In minor categories, both throttle and brake work by wire, but in Formula 1 and other main categories, it is common to see a brake by wire and an electronic accelerator with sensors to control the engine.

Three Design Changes of Motorsport Car Pedal

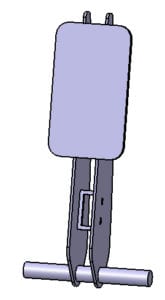

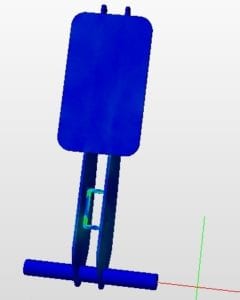

To design my pedal, I considered a system over the soil. For this, the pedal and its base were both included in the CAD design (see below), to control its rotation.

As the pedal is made of aluminum, its weight is 337g. To develop the simulations, I had to study the constraints and loads over the pedal. The main constraints are the different set of parts (to keep them joined) and to block the movement of the assembly. We can also include a restriction of rotation, simulating that we have a spring to control the pedal.

As a load, we should consider the force that the driver can apply on the pedal. To analyze the design’s resistance, I had to consider the maximum force. For F1, for example, this force is about 110kg.

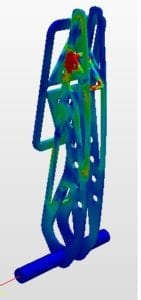

With all these parameters, I could run an FEA simulation and see that this design has no problem supporting the stress to which it is subjected. In any case, the only part that is suffering a bit is the join between both sides of the pedal, but this stress is not a problem.

With the basic design established, the next step was reducing its weight by removing as much volume as possible. To develop this task, you need to follow a matrix design, while trying to keep enough material to support the loads. Following this criteria, I created a new design and simulated it to see if the pedal was weakened or if it was strong enough.

Considering that we have the same scale to show the results, we can see that the component is now suffering more than before. We can also see that we have an area at the top of the side plate where the stress is greater than the acceptable limit, so we should redesign it to ensure that its performance will meet our requirements.

After creating a new design version and a new simulation, we’ve reached a final design. We can now see that our pedal supports the enormous force that the driver applies to it and it is as light as possible. This design has a final weight of 178g, which is 159g less than the first design. This represents a weight reduction of 47%.

The obtained reduction might seem insignificant but, if we consider that we reduce the weight of both pedals and, even more, we use this methodology to lighten up other components, we can achieve reductions of 5-6kg, which can be very useful in an F1 competition, where the difference between victory and defeat can be measured in milliseconds.

Are you interested in learning more about simulation applied in F1 car design? Watch this free webinar: Application of CFD in Formula Student and Formula SAE.

Discover all the simulation features provided by SimScale. Download the document below.