In recent years, cloud-based computer-aided engineering (CAE) has become an important tool in the product development cycle. Today, CAE is used extensively in many industries, such as Automotive, Aerospace, HVAC, Manufacturing, Electronics, and Energy. It not only provides a fast and cost-efficient method for testing existing designs but also allows engineers to optimize them based on new requirements and standards.

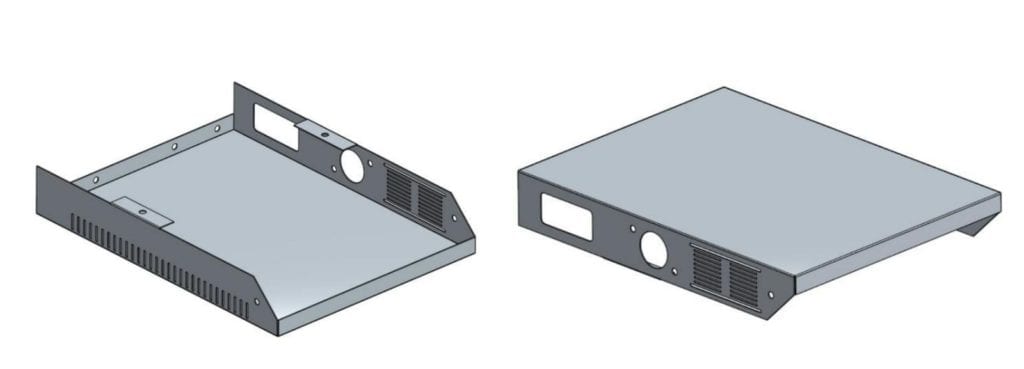

Recently, one of our prospects, who is involved in the manufacturing of sheet metal enclosures, faced a serious problem relating to the failure of a particular design of an enclosure under a pressure load that was supplied to a leading customer. The customer had to reject all the supplied models and due to this. They were about to lose a huge order of supply, as well as future orders.

The prospect was not clear about the reason for the design failure and was unsure of how to fix the problem without any major design change.

Approach to the Sheet Metal Enclosure Problem

The first concern was to study the entire process and understand the various methods that were involved in the design and manufacturing of the part. Through this process, an internal study identified that the enclosure design was done by rule-of-thumb calculations and was only carried by some technical staff with insufficient work experience in this area.

The consequent approach was to perform CAE simulations via the finite element method (FEM) to analyze and improve the structure of the model. The fundamental steps taken were the following:

● Prepare the provided 3D CAD model for analysis

● Perform a stress analysis to measure the structural deformation

● Modify the CAD model by only increasing the sheet metal thickness

● Re-analyze the modified CAD model to see if the deformation is within the tolerances.

Why We selected SimScale as the CAE Tool

Compared to the conventional CAE tools, the SimScale simulation platform is unique as it is completely cloud-based and provides HPC computing power (up to 96 cores per job and 240 GB of RAM) needed to perform large-scale analyses. In addition, it only requires a web browser to access and thus needs no software or hardware installations. This allows testing and analysis of designs anywhere, anytime, and can save substantial costs on hardware.

Another beneficial factor was the ability to upload any neutral file format from a CAD system and the option to import from Onshape (full-cloud CAD solution). It has an inbuilt post-processor that provides a simple and easy way to view the results and a nice graphical user interface (GUI). Here at SolidTrust, the flexibility provided by the option to download results for further processing was appreciated.

Overview of the FEA Simulations

The objective was to identify the stress concentration areas and whether the thickness of aluminum sheet metal enclosure was enough to withstand a pressure load (approximately 500 N) applied to the top face. The type of ‘Structure Mechanics Analysis’ chosen was ‘Static Analysis’ with linear elastic material properties, as the expected load was not large enough to cause plastic deformation. For meshing of the model, the ‘Automatic Tetrahedral’ operation was used and the study was performed.

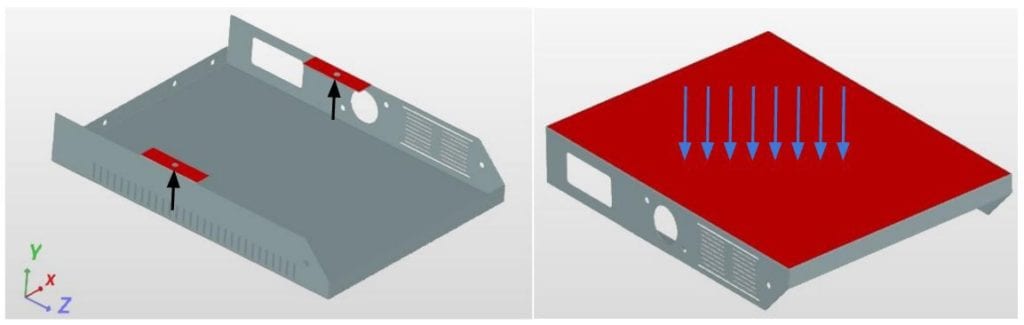

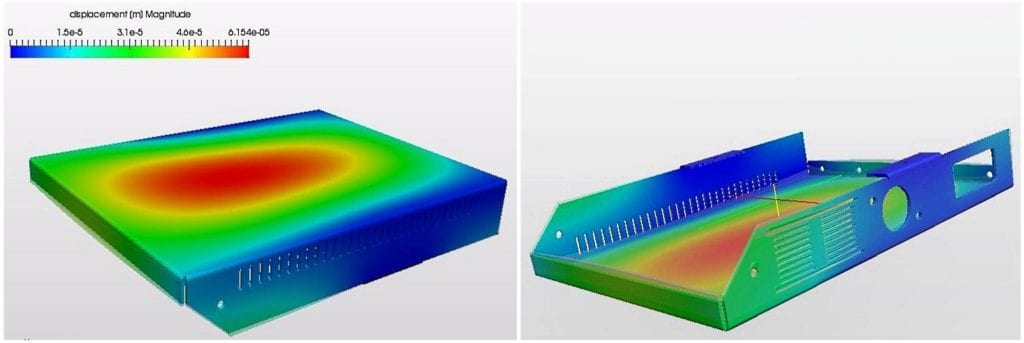

The physical problem was modeled by applying fixed constraints on the two inner flanges and load constraints on the top face of the enclosure. This was carried out using a pressure-based load, as illustrated in the figures below.

Findings and Conclusions

From the FEM analysis, it was found that the original design thickness (~2mm) resulted in displacement areas that were distributed at the enclosure’s center. This displacement was more than the quality standards and was unsafe for the enclosure design.

The design was improved by iteratively increasing the thickness of the cover until it reached a value that resulted in the reduction of the displacement for the load acting area, and to additionally have a maximum displacement well within the Factor of Safety (FoS) limit. Hence the sheet metal enclosure design would be safe for the given load criterion. The results for the improved thickness (~5mm) are shown in the figure below and are superimposed with the enhanced deformation of the original model.

The complete study was performed with relative ease using the SimScale cloud-based CAE solution. SimScale provided advanced capabilities to perform a complicated and demanding analysis that included highly nonlinear behavior, with large rotations, deformations, and physical contacts. Furthermore, we were happy to discover that complex nonlinear material behavior—including plasticity, hyperelasticity, damping, and creep—can also be modeled using SimScale

About SolidTrust Technologies

SolidTrust Technologies is an engineering company that specializes in implementing the latest engineering technologies and products for various industries and research institutes. Backed by decades of experience, and collaborating with engineering and manufacturing companies, SolidTrust has an excellent team of technical engineers and a strong presence in all markets in India.

The company’s focus is customer service and high-quality service. Learn more about SolidTrust Technologies and how you can collaborate on the dedicated company page.

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!