Magnetic lifting devices are essential for moving heavy ferrous materials without direct contact in the mechanical industry. As a designer, understanding how these magnetic lifters work and how to simulate their performance is key to creating better, more reliable devices. SimScale helps you model and analyze your magnetic lifting designs.

In this guide, we’ll look into what magnetic lifting is, how magnetic lifting devices work, and how SimScale improves their design through its electromagnetics simulation tool.

What is Magnetic Lifting?

Magnetic lifting is a method used in mechanical and industrial settings to move heavy metal objects without direct contact. The lifting process is both safe and efficient, particularly when moving large metal items. This technique relies on magnets to create a strong magnetic field that securely attaches to ferrous (iron-containing) materials like steel (not stainless steel, due to its specific metal structure, which makes it non-magnetic).

Smaller magnetic lifting devices can lift between 200 and 400 pounds (~ 100 to 200 kg), suitable for lighter tasks. Larger models are capable of handling hefty loads ranging from 6,000 to 13,000 pounds (~ 2700 to 6000 kg), ideal for more demanding industrial operations. These devices are particularly useful for transporting steel plates, forgings, die castings, and other similar items commonly found in workshops, warehouses, and processing plants.

Types of Magnetic Lifting Devices

Magnetic lifting devices are essential tools in various industrial settings, each type designed for specific applications and capacities. Here are the main types:

Electromagnetic Lifting Magnet

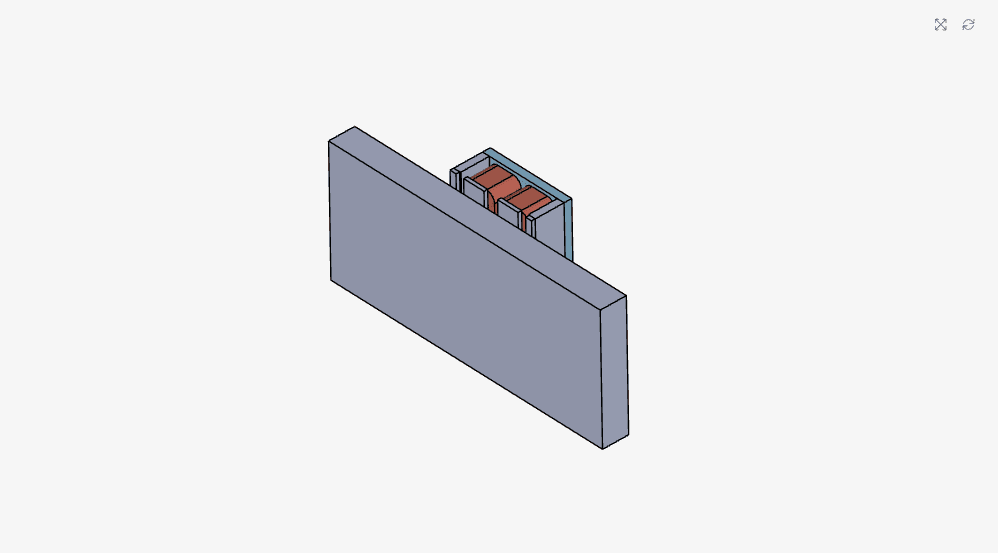

Electromagnetic lifting magnets use an electrical current to create a magnetic field, enabling them to attract and lift ferromagnetic materials. They consist of a coil wound around a ferromagnetic core. When electricity flows through the coil, it generates a magnetic field, allowing the magnet to hold a load securely. The lifting capacity of these magnets can be adjusted by varying the electric current.

They differ from permanent magnets as they require a continuous power source to maintain their magnetic field. Electromagnetic lifting magnets are widely used in industries like scrap yards, manufacturing, and recycling.

Permanent Lifting Magnet

Permanent lifting magnets are built with permanent magnet materials like neodymium or ferrite. These magnets produce a constant magnetic field without needing an external power source. They’re typically used for lifting smaller objects and have a fixed lifting capacity.

These magnets include a block with a main body and a rotor, each containing two magnets. When these magnets are aligned, they generate a magnetic flux that reaches the metal objects to be lifted. One key advantage is their functionality, even during power failures. They’re often found in material handling, sorting, and assembly line applications.

Electropermanent Lifting Magnet

Electropermanent lifting magnets use a mix of permanent magnets and electromagnets to create a magnetic field. Once established, this magnetic field can be maintained without a continuous power supply but can also be turned on or off using an electrical control system. This feature makes them useful when power failure is a concern, such as in steel mills, shipyards, and heavy equipment manufacturing.

When the two sets have the same magnetic direction, the magnet can attract ferromagnetic workpieces. If their magnetic directions are opposite, they cancel each other out, and no magnetic force is generated for clamping. These magnets consist of two magnetic power sources: one set of high intrinsic coercive force (Hci) magnets and another set of low Hci magnets wrapped in electrical wire coils. Changing the direction of the current pulse in the coils can alter the direction of the magnets’ orientation.

Applications of Magnetic Lifting

Here are some examples of magnetic lifting applications in different sectors.

| Application Area | Use Case |

|---|---|

| Manufacturing Industry | Handling of steel sheets and components for vehicle assembly |

| Moving heavy metal parts and machinery components during production | |

| Scrap Yards and Recycling | Sorting and moving ferrous scrap metals |

| Separation and transportation of metallic waste materials | |

| Construction and Infrastructure | Lifting steel beams and frames |

| Positioning of large metal girders and plates | |

| Shipbuilding and Marine | Moving large steel plates and components during ship assembly |

| Handling heavy metal cargo and equipment | |

| Warehousing and Logistics | Moving metal goods and pallets |

| Handling ferrous materials in freight and transportation hubs |

Optimizing Magnetic Lifting Performance through Electromagnetic Simulation

Electromagnetic simulation plays a crucial role in enhancing the performance and efficiency of magnetic lifting devices. Here are several ways in which simulation can optimize magnetic lifting performance.

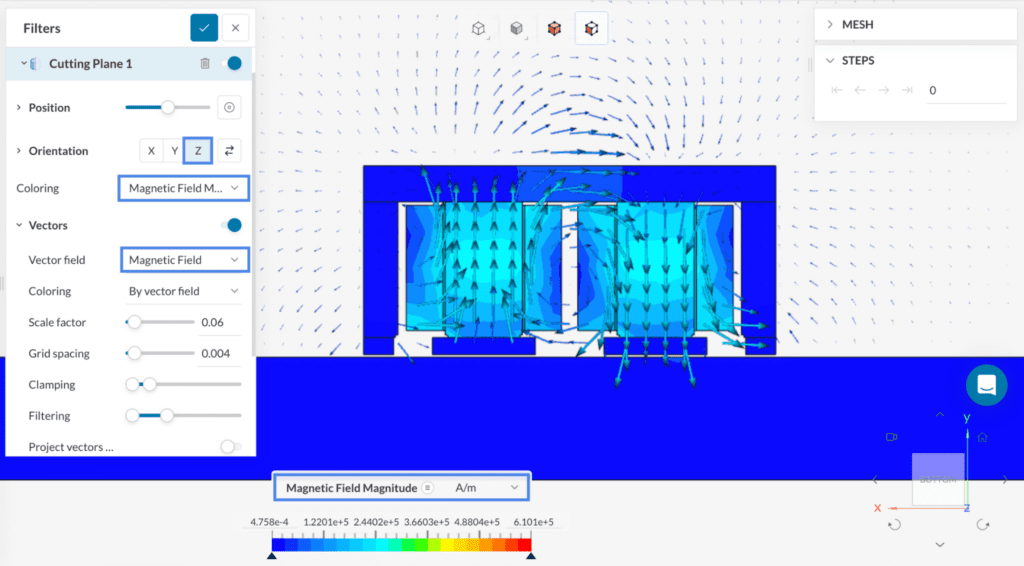

Detailed Magnetic Field Analysis

Electromagnetic simulations can provide a detailed map of the magnetic field’s strength across the lifting surface. For example, they help in ensuring uniform field strength when lifting irregularly shaped objects like curved metal plates or cylindrical steel rolls.

Through magnetic lifting analysis, engineers can detect areas where magnetic flux leakage occurs, which could lead to reduced lifting efficiency or unintended attraction to nearby metal objects.

Load Capacity Optimization

By simulating various load types, including asymmetric and unevenly distributed loads, designers can optimize the magnetic lifter for a wide range of scenarios, such as adapting the lifter design to handle elongated steel beams safely.

It’s easy to simulate how different ferrous materials respond to the magnetic field, considering factors like:

- Material thickness

- Alloy composition

- Surface condition

Enhancing Operational Safety

Engineers can focus more on operational safety by simulating mechanical stresses and strains on the lifting device under different load conditions, such as analyzing the stress distribution on the lifting arm when lifting near the device’s maximum capacity. Magnetic lifter designers can assess the durability of the insulation and electrical wiring, particularly under extreme conditions like high temperature or humidity.

The multiphysics post-processing results, including electromagnetics and thermal analysis, can predict heat generation in the coils and other components during operation. For devices meant for continuous use, simulation helps design systems that can operate for extended periods without overheating.

Energy Efficiency and Sustainability

Engineers can test how quickly the magnetic field can be altered in response to changing conditions, which is crucial in automated systems where rapid adaptation to different loads is required. By adjusting parameters such as the number of coil turns, wire diameter, and coil dimensions, designers can achieve the desired magnetic field strength with lower energy input.

For example, a simulation might reveal that reducing the wire diameter in the coil while increasing the number of turns achieves the same lifting strength with less electrical power required.

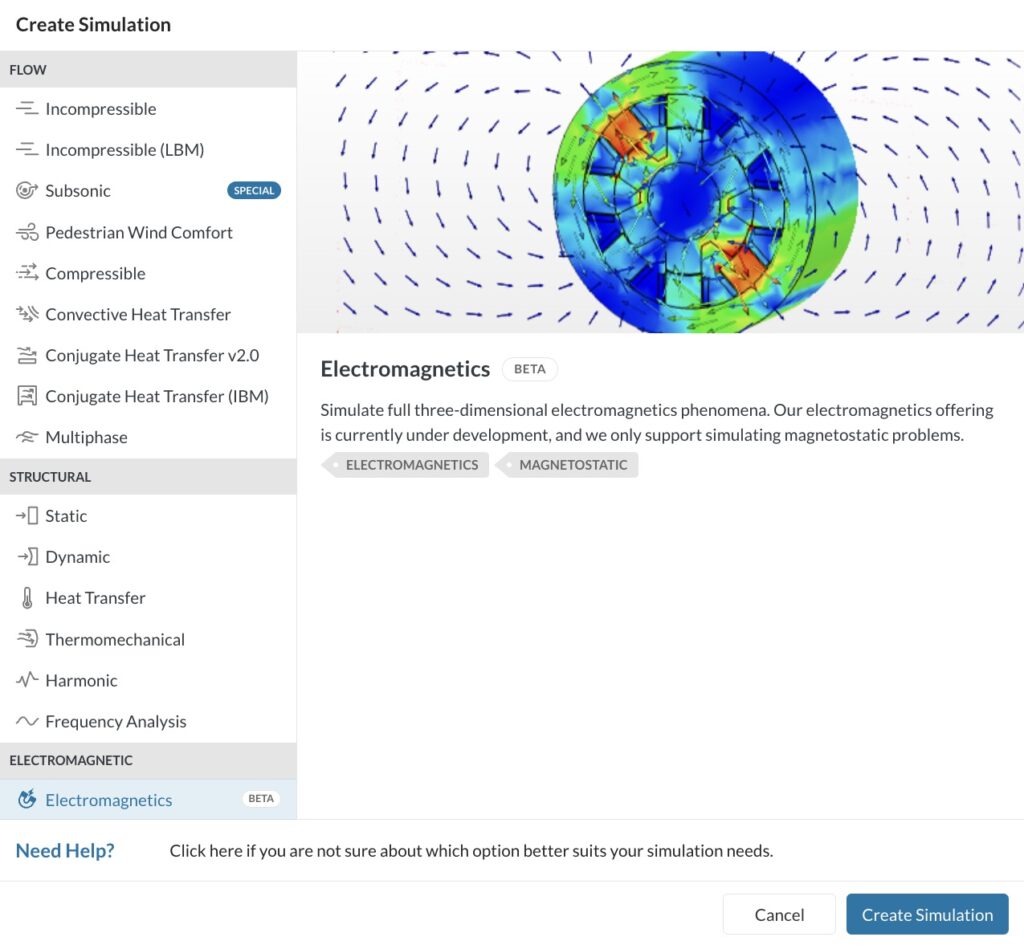

Explore Electromagnetics in SimScale

Magnetic Lifting Simulation with SimScale Electromagnetics

SimScale’s electromagnetic simulation capabilities offer a comprehensive solution for engineers and designers working on magnetic lifting devices.

Browser-Based Electromagnetic Simulation

SimScale allows you to simulate the electromagnetic (EM) performance of electromechanical devices without the need for expensive hardware or complex software installations. You can run multiple simulations in parallel directly in your web browser. This approach significantly accelerates the design process, enabling faster innovation and real-time collaboration.

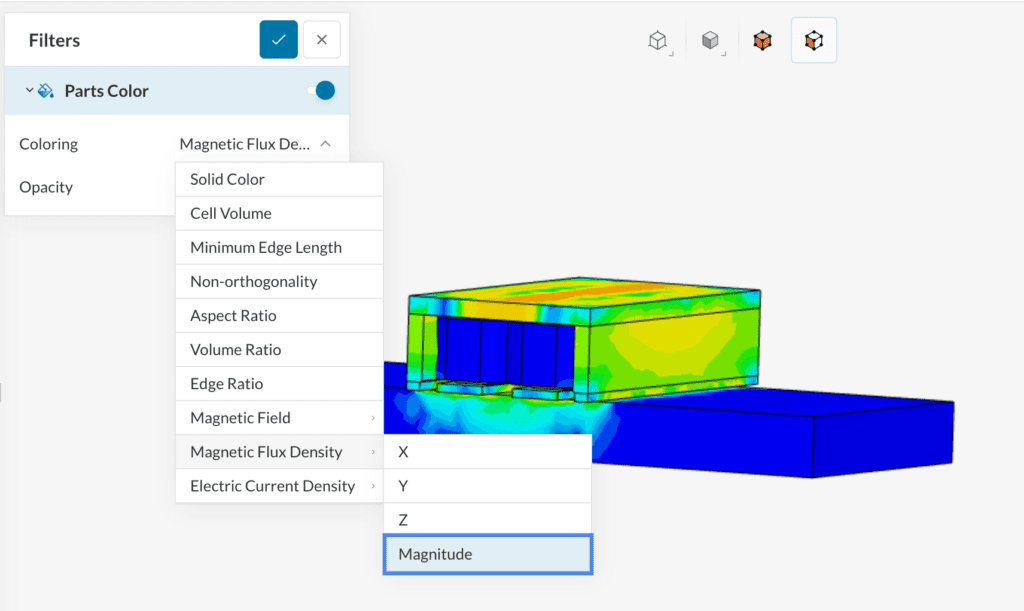

Magnetostatics Tool for Detailed Analysis

The Magnetostatics simulation tool is a core feature of SimScale for magnetic lifting applications. It enables engineers to perform various low-frequency electromagnetics simulations, such as analyzing:

- Magnetic flux density

- Magnetic field strength

- Linear magnetic permeability

- Non-linear magnetic permeability

Simulate Your Magnetic Lifting Machines Using SimScale

Magnetic lifting devices offer a safe, efficient, and contactless method of transport in various industries. SimScale’s Electromagnetic Simulation simplifies the complex task of designing and testing magnetic lifters. Sign up now to start using SimScale, or request a demo to see it in action. You can also learn through our step-by-step tutorial focused on magnetic lifting simulations.

Get started right away with SimScale’s easy-to-use, web-based platform by clicking below—no need for special software or hardware.