As the age-old saying goes, if you can’t stand the heat, get out of the kitchen. However, here at SimScale, our engineers think a little differently. Our office kitchen is fully equipped with stovetops, an oven, and appliances galore for employees to use at their convenience and freely cook their daily meals. It is also the hub for socializing at lunchtime and after work, as well as the place to go for quick catchups with colleagues and coffee refills.

Yet, the heat and smoke from cooking and baking can quickly lead to an unpleasant environment within the kitchen as well as permeate into the rest of the office space if not properly ventilated. Our engineers wanted to ensure we were utilizing proper HVAC techniques, adhering to standards like ASHRAE 55, and ultimately keep employee discomfort in the office to a minimum. This led to our latest thermal comfort simulation: Simulation and Sizzling Steak.

Problem: Kitchen Thermal Comfort

Thermal comfort is defined by ASHRAE 55 and ISO 7730 as “a condition of mind which expresses satisfaction with the thermal environment and is assessed by subjective evaluation”. While comfort may be a subjective condition, in HVAC design, thermal comfort is considered a measurable factor for the safety and satisfaction of occupants based on the calculated PMV and PPD of a given space. The term may lead to the assumption of comfort as a result of temperature, and rightly so, however, there are many more variables (i.e., the metabolic rate of occupants, clothing insulation of occupants, airspeed, humidity, etc.) that factor into the evaluation of thermal comfort.

In addition to comfort, smoke, humidity, ventilation, and harmful air contaminants or odors can also affect occupant (or in this case, employee) safety. The issue of safety is accentuated in a kitchen environment within a workplace, as these factors can strongly impact on employee satisfaction as well as create legal issues for the company if not dealt with accordingly.

Solution: CFD Simulation

Poor thermal comfort and a lack of ventilation in an office space can lead to productivity loss, employee turnover, heat stress and in extreme cases even serious heat-related illnesses in hotter climates. While there are standards to comply with—such as ASHRAE 55 and ISO 7730—and guidelines to follow which engineers can use to assess thermal comfort in a space, assessing the thermal comfort of a room can also be supported by computational fluid dynamics (CFD).

CFD, through online platforms like SimScale, can be used to reveal many insights into the airflow, ventilation efficiency, and radiant heat transfer. Heat is a serious issue in kitchens, with ovens, stovetops, kitchen appliances, and the staff themselves working constantly for long periods of time. Using convective heat transfer analysis, an HVAC engineer or designer can assess how heat is transferred and identify areas of extreme temperatures that should be assessed. With this knowledge, the engineer is able to see how ventilation devices, exhaust hoods, appliance positioning or natural ventilation efforts be implemented.

Convective Heat Transfer Simulation Our Case: SimScale Kitchen

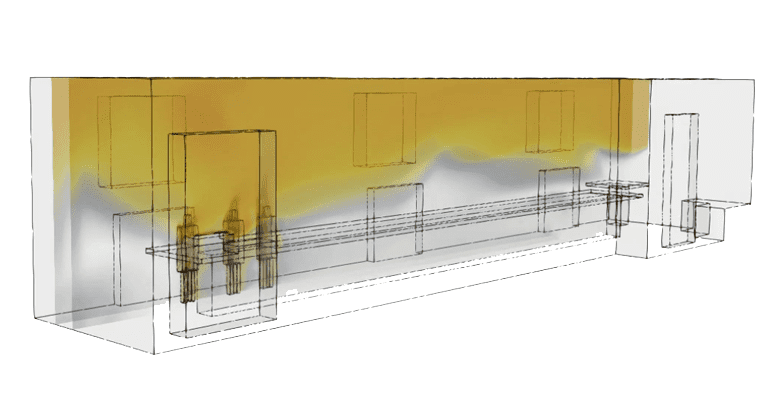

In order to demonstrate the use of convective heat transfer simulation for a kitchen HVAC design, the SimScale kitchen was designed and simulated with the scenario of someone frying a steak—an action that can typically produce uncomfortable levels of heat and smoke.

Convective heat transfer analysis is used for scenarios where temperature changes in the fluid lead to density changes. The latter cause the fluid to circulate under the influence of gravity. This type of simulation can also take into account radiation. To learn more about heat transfer analysis, check out this documentation page.

The Simulation Setup

A CAD model designed with Onshape was created and imported in the SimScale workbench, complete with a stovetop, table, three people, windows, and doors. The mesh was then created, the gravity direction and intensity were defined, and coefficients for the passive scalar (smoke coming from the steak) also defined.

Air for the fluid domain was then chosen for materials, the boundary conditions (including the radiator, people, stove, etc.) were selected with fixed temperature values, and inlet and outlet parameters set. Finally, the smoke source area was defined within the advanced concepts in SimScale.

The Simulation Results

Looking at the velocity field of a horizontal slice 3m from the floor, the results found that air flows through the main door towards the windows removing the smoke from the stove. This also revealed that the central window gives an important contribution to smoke and heat extraction. Ultimately, the simulation found that by opening the kitchen door and the window closest to the stove is very effective in clearing smoke and ventilating the room. Watch the whole video below.

Additional Thermal Comfort Resources From SimScale

- What Is PMV? What Is PPD? The Basics of Thermal Comfort

- What Is ASHRAE 55? Basics of Thermal Comfort

- Thermal Comfort and Radiation with SimScale

- Radiation and Thermal Comfort for Indoor Spaces

- Ensuring Thermal Comfort with HVAC for a School Building Design: Case Study Ramboll

- ASHRAE Standard 55 Thermal Comfort Assessment with Simulation

- How to Comply With EN 15251 and EPBD – Thermal Comfort & More