Inspired by the engineer, futurist, and fellow-Croatian Nikola Tesla, Mate Rimac founded Rimac Automobili in 2009. Rimac’s agile approach has delivered impressive progress in an incredibly short amount of time.

Today, the company develops high-performance electric drivetrain and battery systems for many of the world’s largest automotive manufacturers. Its customers include Aston Martin, Porsche, Koenigsegg, Cupra, and many more.

Rimac, known for its electric hypercars, is working on highly efficient battery solutions for the most demanding projects and conditions in the automotive industry. In this article, we explore Rimac Automobili‘s approach to simulation and learn how they leverage cloud-native engineering simulation within their battery pack team design and beyond.

Multiphysics Simulation and Product Development at Rimac

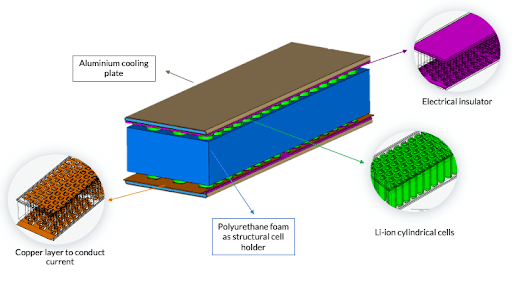

SimScale is used by several different departments responsible for designing components for battery packs and for testing the structural integrity of components. Currently, Rimac’s design engineers count on SimScale as a tool in their stack that augments their simulation capabilities. Battery System Engineer Antonio Radenić shares that the team’s main interest lies in heat transfer phenomena. They perform thermal simulations to determine the thermal gradients and hot spot areas they can expect on various concepts and designs.

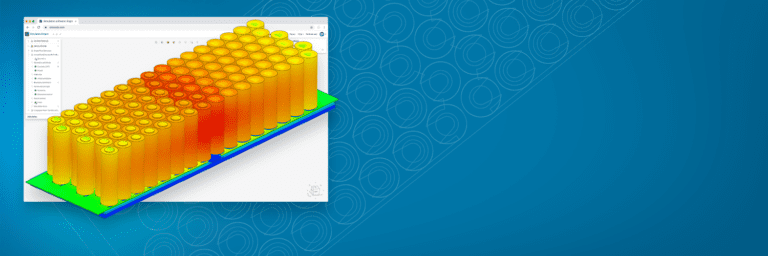

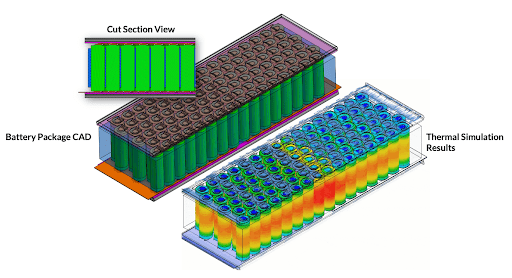

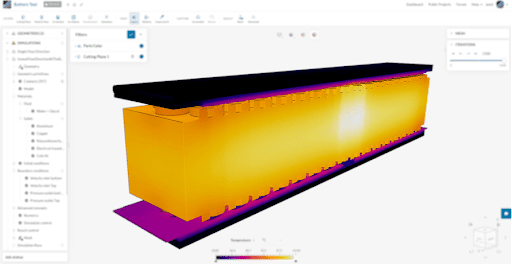

The cooling performance assessed in the project shown below includes the maximum temperatures reached by the battery pack cells, as well as the battery gradient, which is essential for optimal battery performance. The parameter studies included a variation of the inlet flow velocity as well as the thermal conductivity of the electrical insulator.

These types of studies assure Rimac designers reliability, expected lifespan, and safety of their product. Conducting them with cloud-native engineering simulation means the turn-around time of investigating multiple design iterations is drastically reduced.

As SimScale was born in the cloud, it’s scalable by nature. This gives the design team an edge over traditional CAE tools. Computational power can scale up or down depending on project demand and multiple design options can be explored across multiple teams within Rimac, as cloud-native tools have sharing and collaboration features baked in.

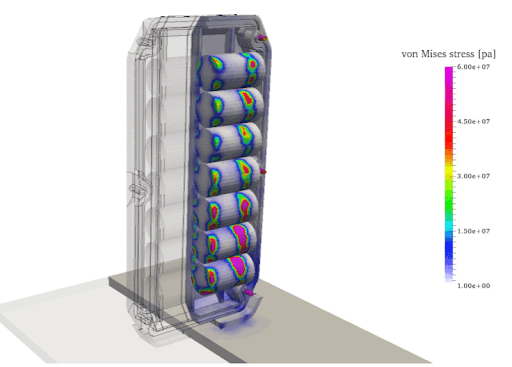

Rimac is interested in exploring the full physical spectrum of the battery packs, which includes testing the structural integrity of their designs. With simulation, they can determine the type of stresses they might expect in their structures and cooling elements and the type of loads that might occur with applied pressure inside various geometries.

With electronics design, investigating thermal aspects is often at the center of the product development process. But Rimac’s work offers many areas of investigation for which multiphysics simulation can be used. A battery pack drop test analysis, for example, represents an opportunity to investigate and improve product safety.

CFD analysis only begins to scratch the surface of the type of design space exploration available to engineers using multiphysics simulation in the cloud. Access to cloud computing enables users to kick off simulations in parallel, meaning in the same amount of time that traditional CAE might require for one simulation run, designers at Rimac can explore the specifics of multiple designs, quickly iterate from there and make fast design decisions.

Simulating Designs for Electric Hypercars

The introduction of SimScale into the R&D process of Rimac Automobili has empowered them to accurately and efficiently simulate hundreds of virtual battery pack models, including a wide range of complex real-life hypercar driving cycles and scenarios. In the future, they plan to expand the use of SimScale between and across different departments to fully avail themselves of the benefits of a SaaS engineering tool in a highly competitive automotive market. Providing their design team with access to multiphysics simulation allows Rimac to optimize at the top of their field, pushing the boundaries of design with the next generation of electric hypercars.

Watch our on-demand webinar with Rimac Automobili, where presenters showcase a Design of Experiments (DoE) study seeking to increase battery life while maintaining an optimal operating temperature inside the battery module: