HVAC systems are a critical component and consideration for professionals operating in a variety of fields, from construction and architecture to automotive industries. HVAC designers and engineers face a number of challenges when it comes to product manufacturing, smart buildings, or modern plant infrastructure design.

Engineering simulation is being increasingly adopted in the design process as a strategy to address these challenges and to ensure the energy efficiency and optimal performance of HVAC equipment.

HVAC Design Challenges in HVAC System Design Processes

A classic HVAC system design process is based on four elementary steps:

Design > Physical Prototyping > Testing > Design Change

There are several critical issues that arise in relation to the quality, time, and costs related to the prototyping cycle.

Finding an acceptable solution in a reasonable time—and with reasonable costs—can only be achieved by working with very experienced HVAC system design teams. Otherwise, the testing process can involve hundreds of prototype changes and iterations, leading to unpredictable scheduling and costs that are impossible to predict. The unpredictable costs associated with the supply and the need for testing laboratory activities also need to be considered from the outset. The process of prototyping and testing can take weeks, and sometimes HVAC designers or architects don’t have this time available in the design schedule.

HVAC Simulation Saving Time and Money with Simulation

By implementing simulation activities, the HVAC system design process is radically simplified:

Design > Simulation (CAE) > Design Changes

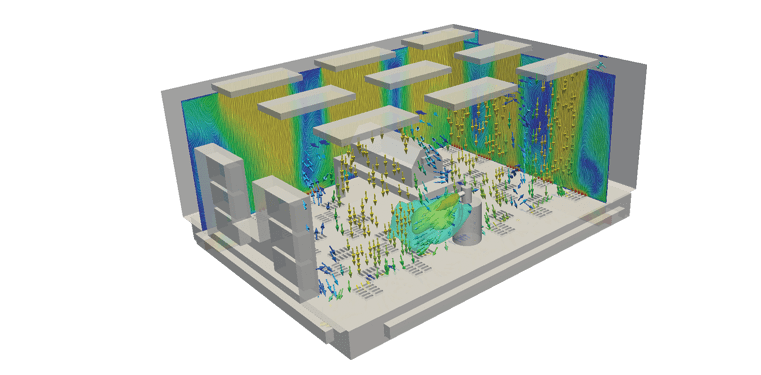

For HVAC systems, designers and engineers will typically perform fluid dynamics (CFD) and thermal simulations to improve the air conditioning circulation and comfort factors for different indoor or outdoor scenarios. HVAC product designers can drastically enhance the characteristics of equipment by analyzing simulation charts for factors like temperature, pressure, and velocity distribution. The study of aerodynamic or thermodynamic forces is very useful in identifying the optimal equipment position for a specific location.

Noise reduction is another important factor in creating a pleasant living and working environment. The most common sources of noise pollution in the work environment are related to fans, variable air volume systems, grilles and diffusers, chillers, compressors, pumps, standby generators, boilers, and cooling towers. The alternative solutions that can help to reduce noise pollution are silent ventilation equipment, silencers and insulation materials for HVAC protection, or implementing a noise optimization analysis.

HVAC Systems 5 Tips for HVAC System Design

1. Engineer – Designer Tandem Collaboration

In a typical product development process, engineers and product designers work together, but they often have different goals for their projects. Engineers are more interested in the product’s reliability, quality, dimensional details, materials supply, or manufacturing processes. In contrast, designers are more oriented towards features, customer experience, and competitive alternatives. It is important that all team members work in tandem to achieve the main goals of the overall project. All modern simulation solutions facilitate seamless communication and collaboration to ensure these goals are met.

2. Looking for a Perfect Fit

Acting as essential creation poles in the HVAC product development chain, the role of an HVAC designer is to ensure a perfect fit between product functionality and design. Any new product should primarily be simple to use and attractive by its simplicity.

3. Improving Existing Products

Customers need more practical, functional, and higher quality products than ever before. Before starting working on the design concept, the product designer should study existing HVAC products and investigate competitor’s key features and functionalities.

4. Testing

HVAC system design teams should benchmark new products, evaluating how new features and functionalities can be implemented into the existing product design.

5. Trusting Simulation

Simulation technology is a valuable part of the design process. When considering industry purposes, HVAC system design specialists should make use of the virtual prototyping offered by Computer-Aided Engineering. There are many traditional simulation software packages available on the market with a wide range of available features and capabilities.

Many of these technologies are, however, inaccessible to most professionals and companies due to the large upfront investment that is required, lack of technical expertise, and accessibility restrictions.

Since the launch of SimScale’s cloud-based CAE platform, however, the world of engineering simulation has begun to change. Engineers and designers now have access to powerful simulation capabilities within an easy-to-use, cloud-based platform that can be accessed with a standard laptop or desktop computer.

Download this case study for free to learn how the SimScale CFD platform was used to investigate a ducting system and optimize its performance.