Electric motors power all sorts of applications today, from industrial machinery to electric vehicles and consumer electronics, driving efficiency, productivity, and innovation across industries. However, ensuring their reliable performance requires thorough testing to prevent overheating, insulation breakdown, and mechanical failure. Otherwise, the situation often snowballs into safety hazards, equipment damage, and major losses for your client.

With engineering simulation now a critical part of motor testing, engineers can analyze thermal behavior, predict electromagnetic performance, and identify design flaws before physical testing even begins. In this guide, we will explore how to test an electric motor, its advantages, and the different test methods that guarantee safety and efficiency.

Introduction to Electric Motor Testing

Electric motor testing is the process of evaluating the performance, reliability, and safety of an electric motor before manufacturing begins. It includes testing factors like electrical parameters, mechanical integrity, and thermal stability to ensure the motor runs well over the long haul.

Electric motor-driven systems consume around 46% of the world’s produced electricity. When a motor underperforms, it directly hits efficiency, safety, and operational costs.

We’re not talking about the price tag of just the motor itself here—that’s a drop in the bucket compared to what it costs to operate and maintain it. To truly understand the expense of an electric motor, you have to look at the Total Cost of Ownership (COO), which is broken down like this:

COO = Purchase Price + Cost of running + Cost of not running

The cost of operating the motor—think energy consumption and routine maintenance—often makes up about 70–95% of the total expense over its service life, which could span 20 years or more.

Before building a physical prototype, a simulation-driven electric motor design lets you optimize performance parameters and spot potential issues. Running virtual tests on your motor helps you see into the future—how your electric motor will perform five years down the line after continuous load variations and environmental stresses.

Types of Electric Motor Tests

Electric motors endure a wide range of stresses, so they must be tested mechanically, electrically, and thermally to ensure optimal performance and longevity.

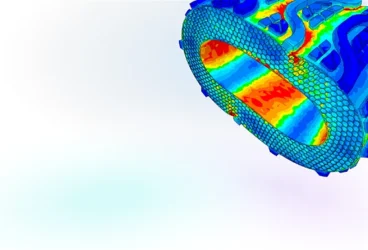

Electrical and Electromagnetic Testing

Electric and electromagnetic testing ensures that the motor’s electrical parameters align with design specs and that the electromagnetic interactions within the motor are optimized for efficiency and minimal losses.

Proper analysis can prevent potential issues like electromagnetic interference, unexpected power loss, or thermal overheating, which could ultimately lead to motor failure or sub-optimal performance.

Engineers should pay close attention to the following parameters when running electrical and electromagnetic tests:

- Winding resistance and inductance: Evaluate copper losses and magnetic behavior

- Insulation resistance: Ensure no short circuits develop between the windings and motor frame

- Magnetic flux density: Measure the strength of the magnetic field within the motor, impacting torque and efficiency

- Electromagnetic field distribution: Identify potential hotspots and irregularities in magnetic field lines

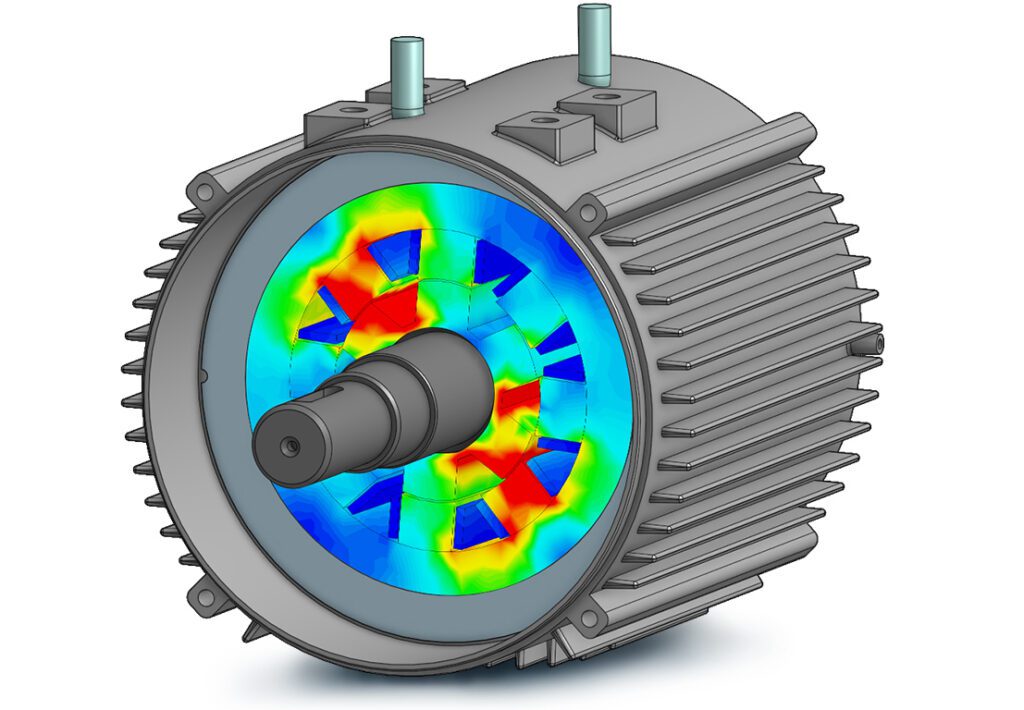

SimScale is a cloud-based simulation platform that allows engineers to analyze and optimize electric motor designs through various electromagnetic simulation tools, including magnetostatics, time-harmonic magnetics (AC magnetics), and electrostatics.

These tools enable the visualization and analysis of key parameters like magnetic fields, current densities, and electric charges, allowing for parallel simulations and design iterations to improve motor efficiency and performance before physical prototyping.

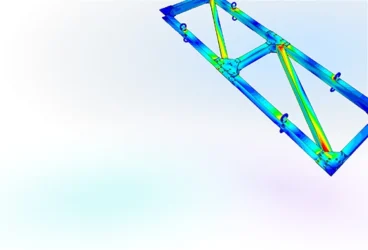

Mechanical Testing

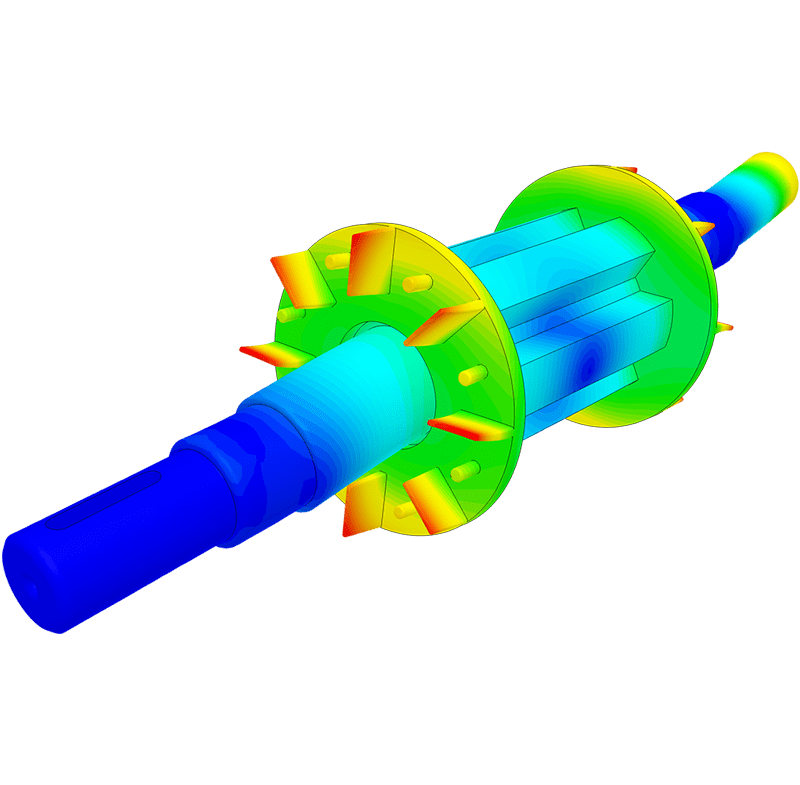

Mechanical testing identifies how the motor’s components behave under mechanical loads, including rotational forces and vibrations. It’s usually done using Finite Element Analysis (FEA), a powerful simulation tool for evaluating the physical properties of an electric motor’s components.

A well-designed mechanical structure ensures the motor runs smoothly, minimizes noise and wear, and maintains performance over its lifespan.

Engineers need to analyze the following mechanical parameters to ensure the motor’s structural reliability:

- Bearing load and life expectancy: Assess the distribution of forces on bearings to avoid premature wear

- Thermal expansion and stress: Analyze how temperature changes affect material properties and structural integrity

- Fatigue analysis: Study how repeated loads impact motor components over time to predict potential failures

- Torque and rotational forces: Measure forces exerted on components to ensure efficient transfer of power

- Mechanical resonance: Identify natural frequencies that could lead to destructive vibrations under certain loads

SimScale provides cloud-based mechanical simulation tools for engineers to analyze structural behavior in electric motor components. Its capabilities include static stress and deformation analysis, dynamic response to shock or vibrations, and modal analysis to identify natural frequencies.

Additionally, it allows thermomechanical simulations to assess how temperature changes impact motor structures, offering a comprehensive approach to optimizing designs before prototyping.

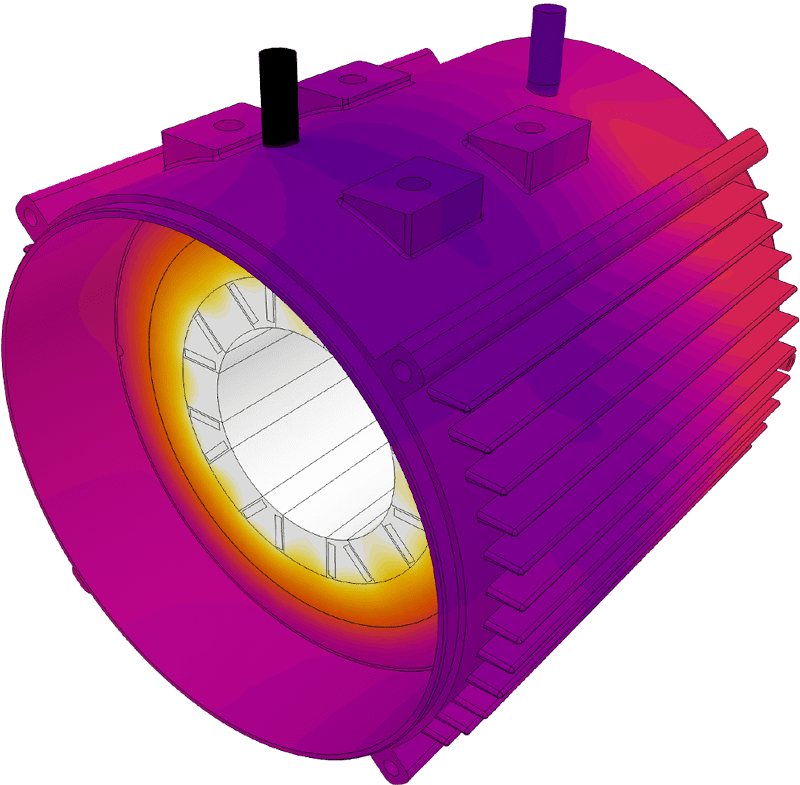

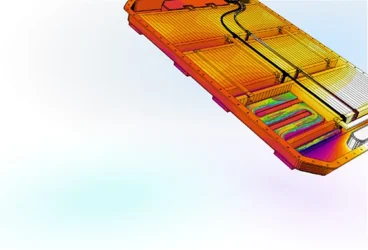

Thermal Testing

Heat is a critical factor in electric motor performance and, if not properly managed, can lead to component degradation, reduced efficiency, and, eventually, motor failure.

Motors must effectively dissipate heat to maintain optimal performance, as excessive temperatures can damage windings, bearings, and insulation. Thermal testing is essential in assessing how well a motor handles heat over time.

For comprehensive thermal analysis, engineers should evaluate:

- Heat dissipation efficiency: Assess how effectively the motor can release heat into its surroundings

- Temperature rise in windings: Monitor winding temperature to prevent insulation breakdown and motor burnout

- Thermal conductivity of materials: Evaluate how different materials conduct heat within motor components

- Ambient temperature and cooling methods: Understand the effect of surrounding temperature and cooling techniques like convection, conduction, and radiation

- Thermal gradients: Identify temperature differences across different sections of the motor that could lead to mechanical stress

- Hot spots and thermal resistance: Detect areas of high thermal concentration and resistance paths to optimize heat flow

SimScale’s platform offers comprehensive simulation tools for thermal management, allowing engineers to analyze heat transfer through conduction in solids, convection in fluids, and radiative heat transfer.

The platform can simulate various scenarios, including forced and natural convection, cooling efficiency, and the effect of thermal loads on mechanical structures.

Performance Testing

Performance testing evaluates an electric motor’s operational characteristics to ensure it meets its designed capabilities. The goal is to simulate real-world conditions and validate that the motor performs optimally throughout its expected load range and applications.

The following key performance tests reveal how well a motor can maintain torque, speed, and efficiency across its working range, helping engineers optimize its design for consistent and reliable performance.

- Load Testing: This test measures the motor’s response under various load conditions to understand its behavior under full, half, or overload scenarios. It identifies any drop in performance, helping engineers verify that the motor can handle its rated load without overheating or excessive vibration.

- Torque Measurement: This test assesses the torque the motor produces at different operating speeds and load levels. This is crucial for understanding how well the motor can drive its intended application, particularly in dynamic systems where torque variations can significantly impact performance.

- Speed vs. Load Characteristics: This test evaluates the motor’s ability to maintain consistent speed as the load changes. In real-world applications, motors may experience fluctuating loads, so understanding how speed varies with load is vital for ensuring stable performance.

- Efficiency Testing: This test analyzes the motor’s ability to convert electrical energy into mechanical output. Here, the focus is on parameters like power factor, losses (electrical, mechanical, and thermal), and overall efficiency to maximize performance and minimize energy costs over the motor’s lifecycle.

Electric Motor Testing Standards

Electric motor testing is governed by several key standards to ensure safety, reliability, and compliance across various applications. These standards are developed by organizations such as:

- IEEE (Institute of Electrical and Electronics Engineers)

- NEMA (National Electrical Manufacturers Association)

- IEC (International Electrotechnical Commission)

- BSI (British Standards Institution)

- JISC (Japanese Industrial Standards Committee)

Each organization sets guidelines for testing procedures, performance benchmarks, and safety requirements.

Engineers must understand and follow the appropriate standards as they vary based on motor type, intended application, and geographical region. For instance, testing requirements for motors used in explosive environments (ATEX) differ significantly from those for standard industrial applications.

Likewise, motors destined for the North American market may need to comply with NEMA standards, while those aimed at a global market may need to align with IEC regulations.

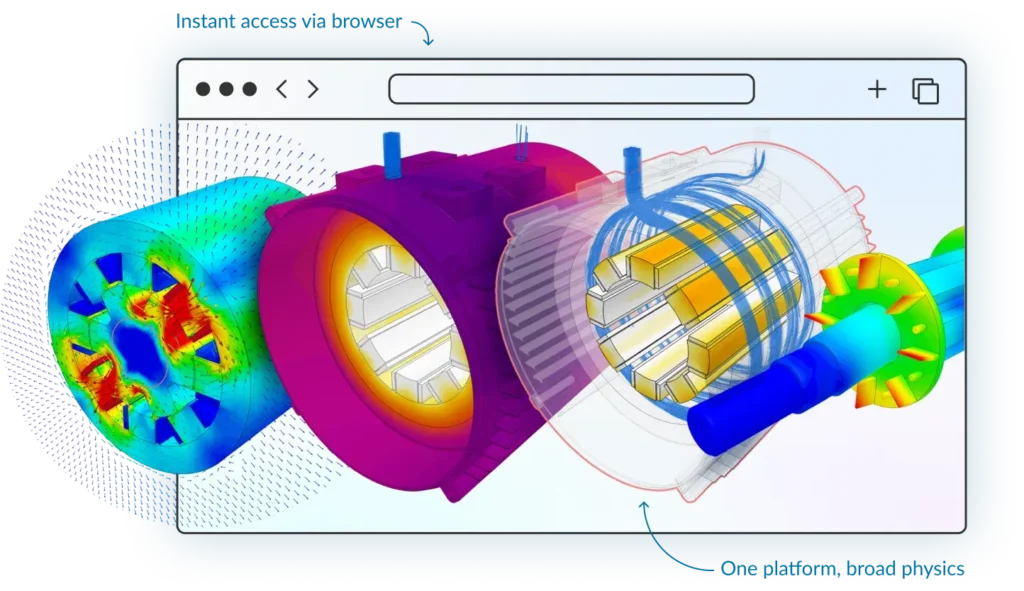

Advantages of Using SimScale for Motor Testing and Optimization

Optimizing motor performance is crucial in many engineering applications today, where time and cost constraints demand efficient solutions. SimScale’s cloud-native platform streamlines electric motor testing by enabling scalable simulations, real-time collaboration, and comprehensive multiphysics analysis. These tools help engineers identify issues early, make faster adjustments, and reduce the need for extensive physical testing.

Here are some key advantages of using SimScale to optimize motor performance:

- Scalability: Run multiple simulations simultaneously without investing in costly hardware, leveraging the power of cloud computing.

- Real-time collaboration: Collaborate with team members on motor testing projects remotely, sharing projects in real-time with editing capabilities to enhance workflow efficiency.

- Multiphysics simulation: Analyze the motor’s electrical, mechanical, and thermal interactions together to gain a complete understanding of performance under varied conditions.

- Shorter development cycles: Identify performance issues early in the design phase through simulation, enabling quicker optimization and reducing the need for extensive physical prototyping.

- Reduced costs: Lower expenses associated with physical testing, hardware setup, and prototyping by relying on accurate and fast virtual simulations.

- Quicker iterations: Make rapid design changes and test modifications swiftly without long delays between iterations, leading to more refined end products.

- Parallel testing and Parameterization: Run multiple test scenarios at the same time to explore different design variables and conditions, optimizing the motor faster and more effectively.

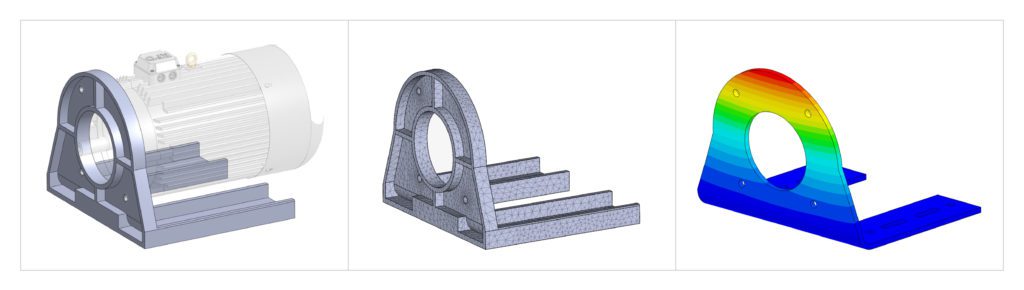

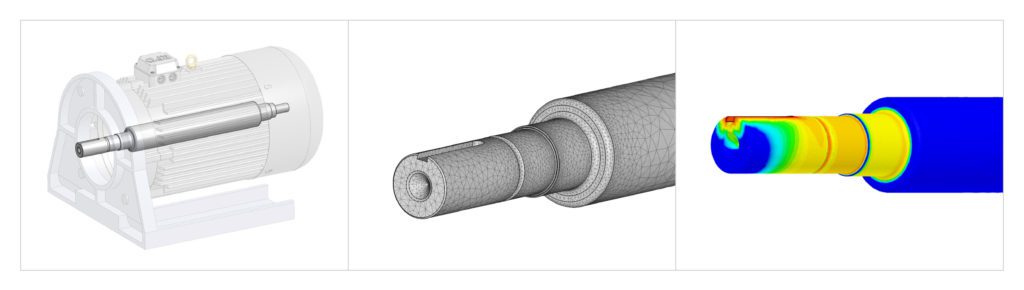

A case study on SimScale’s platform showcases the structural and vibration analysis of an electric motor support bracket. Engineers ran a modal analysis to ensure the bracket’s natural frequencies were outside the motor’s operating speed, preventing damage and resonance issues.

SimScale’s cloud-native platform allowed for quick CAD changes, shifting the first eigenfrequency away from potential risk zones. The engineers also checked the motor shaft’s safety factor under applied torque to confirm that it met stress limits.

Using finite element analysis (FEA), the cloud platform enabled easy CAD imports, automated meshing, and seamless simulation setup. The bracket’s vibration behavior and the shaft’s structural integrity were assessed, providing key data on stresses, displacements, and frequencies to optimize the design and ensure safe operation under real-world conditions.

How to Test an Electric Motor in SimScale: A Step-by-Step Guide

This guide will help you understand how to set up your simulation in SimScale, use the platform’s tools effectively, and gain insights into motor behavior under different conditions.

Step 1: Import Your CAD Model

Begin by importing the CAD model of your electric motor or any components you want to test. SimScale supports all CAD formats and integrates with tools like Onshape, Solidworks, Autodesk Fusion 360, and more (See the full integrations list here).

You can also perform basic CAD operations directly in SimScale, making quick adjustments without leaving the platform.

Step 2: Create and Set Up a Mesh

Once your geometry is ready, create a mesh to discretize the model into smaller elements for simulation. SimScale provides automated meshing options tailored to different simulation needs, including Snappy Hex Mesh for internal flow analysis and tetrahedral meshing for more complex shapes.

Mesh fineness can be set automatically, with control over layers near walls to ensure accurate results.

Step 3: Define Simulation Type

Choose the type of simulation based on your analysis goal—structural mechanics, thermal behavior, fluid flow, or acoustic analysis. For electric motors, common choices include:

- Thermal Simulation to assess heat transfer and cooling

- Modal Analysis to identify natural frequencies and avoid resonance

- Static or Dynamic Mechanical Analysis to evaluate load responses or vibrations

- Electromagnetic Simulation to study electromagnetic interference and behavior

Step 4: Assign Materials and Properties

Assign appropriate material properties from SimScale’s materials library, which includes standard parameters like density, thermal conductivity, and elasticity. You can also customize properties to meet specific needs.

Materials should be accurately defined for the motor components (e.g., shaft, casing) to ensure realistic simulation results.

Step 5: Set Initial and Boundary Conditions

Define how your motor will interact with its surroundings by setting initial and boundary conditions. These include inlet and outlet flow rates, torque loads on the shaft, fixed or rotating components, and temperature gradients for thermal analysis.

Accurately setting these parameters is crucial as they define the real-world operating conditions for your simulation.

Step 6: Run the Simulation

SimScale’s cloud-native platform allows for parallel processing, so you can run multiple simulations simultaneously without needing powerful local hardware.

During this phase, the platform will solve the governing equations for the defined conditions, and you’ll be able to track progress and convergence plots in real time.

Step 7: Post-Processing and Analyzing Results

Once the simulation is complete, use SimScale’s post-processing tools to visualize results. You can evaluate pressure distribution, temperature profiles, displacement magnitudes, and stress-strain responses across different components of your electric motor.

The platform supports slicing, streamlines, and custom plots to better understand your motor’s performance.

Conclusion

You can identify potential performance issues early on by simulating your electric motor’s behavior under various electrical, mechanical, and thermal stresses. SimScale brings all these testing capabilities to your fingertips. Instead of spending time and money on physical prototypes and lengthy test cycles, you can use SimScale’s cloud-based platform to run parallel simulations, tweak designs quickly, and ensure your motor meets all performance and safety standards.

If you’re ready to take your motor testing to the next level, try SimScale for free, or check out our guided demo to see how it can help you design better, more reliable motors.