Dr. Pawel Sosnowski has been working as the Lead Sales Engineer at SimScale since January 2015. He holds a Ph.D. in Environmental and Industrial Fluid Mechanics from University of Trieste (Italy). The focus of his Ph.D. was numerical simulations and computational fluid dynamics (CFD). At SimScale, Dr. Sosnowski uses his experience to ensure a high-level of technical background in the sales department and takes care of training, customer coaching and direct support.

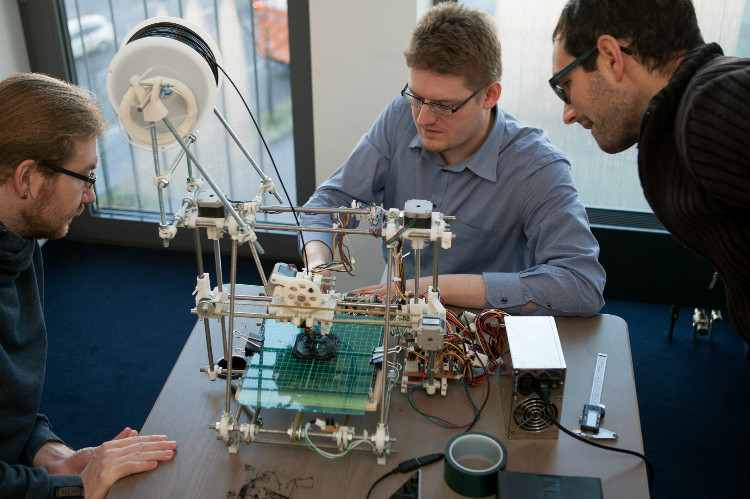

We interviewed him to find out how our readers can build a 3D printer without any previous experience.

Most of our customers already know how experienced you are as CAE specialist, they met you during the CAE Professional Trainings, but the rest of the world doesn’t know yet how many interesting things you do. Let’s start with your 3D printer. How did you decide to work on such a complex project?

I found out about 3D printers a few years back, during a business course I was attending. People were talking about them, and I just thought it would be nice to have one. Then I noticed that the price of commercial 3D printers—even though they’re getting reasonable—was quite high. I was a student, and two thousand euros was quite a lot for me. So, I decided to find another way, to read about how to build a 3D printer on my own.

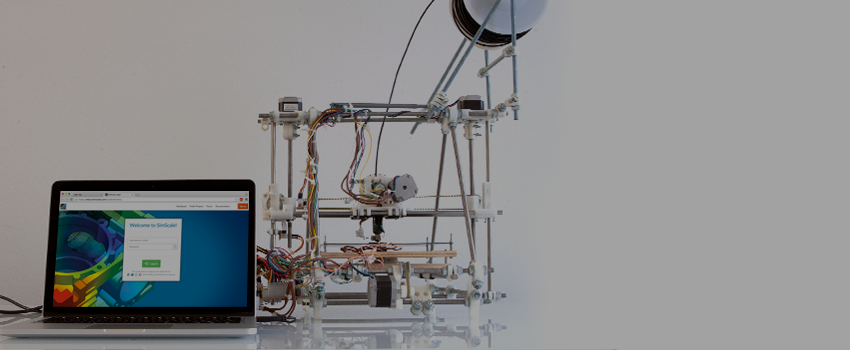

I came across RepRap, the open-source 3D printers that can print parts for themselves. I began planning out the project and reading lots of material on the Internet—everything you need is there. Then I started making a list of parts that would be required to build a 3D printer and slowly buy them online or in metal shops.

How long did it take you to build the 3D printer, and how did you do it?

The period was split in two. First was the time to acquire the parts; second—the assembling. The printer assembling time, if you have all the parts, takes around four hours. You can finish one in a day supposing that you have the tools, parts and electronics. If you want to solder the electronics yourself, add extra few days.

So, you also built the electronics?

Yes. It was supposed to be a hobby, so I said: “Let’s make it from scratch”.

When you look at all the elapsed time, you might get an impression that it is quite short. But you need to consider the time you need to plan things and acquire the parts. Even if you have the materials, like metal bars, you have to cut them or search for a friend who has the tools.

In the end, the 3D printer took me a year to build. Then again, nothing was rushing me (laughing).

Were the parts for the 3D printer expensive?

That’s the interesting thing. With the RepRap, you can build a 3D printer with the investment of €400. If you don’t have the tools, like wrenches or solderer, you might require an extra €100—so 500€ in total. If this price still seems pretty steep, consider that you will divide it over a year which makes it quite bearable.

Did you have any previous knowledge of how to build a 3D printer?

No, I did not have any knowledge or experience before. Just saw one or two 3D printers during some exhibitions. If it counts, I played a lot with LEGOs when I was a kid (smiling).

SimScale’s CEO David Heiny tests the capabilities of cloud-based simulation to solve an engineering problem. Fill out the form and watch this free webinar recording to learn more!

What was the first thing you printed with it?

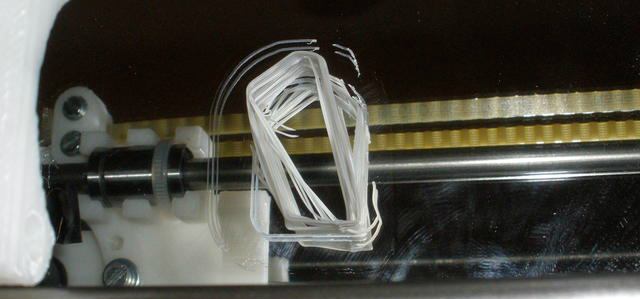

This was just a test print. Basically, it was supposed to be a small box-like shape that was checking the calibration of the 3D printer—it was terrible! The plastic did not stick, the layers didn’t stack… just take a look at the picture. After some calibration, it got better.

One of the first “real” projects I did was a little heart for my wife. She deserved it for keeping up with me changing half of the kitchen for a small workshop.

That’s very nice! And how did you know how to fix the calibration problems?

That’s the amazing thing about the RepRap, all the required information is available online, and there’s a huge community of people who are making designs, printing them, sharing their expertise and knowledge.

On the other hand, this large amount of data and instructions can get a little overwhelming when you’re starting from scratch. In the end, it all comes down to experience and experimenting.

For example, now I know that I should have used different motors. I did not read deep enough to know which ones work best. Also, I would choose a different kind of the hobbed bolt which pushes the plastic. And I would most likely have a bigger extruder—my extrusion opening is 0.35mm, which increases the printing time. These are the things that you learn later. After the first printer that you build, you’re ready to make a second.

So far, I keep improving the printer. For example, I made a stack to hold the plastic on. I also included a diverter for the Y-axis drive. The belt didn’t have enough tension, and I was losing precision.

You also printed some dollars. What’s the story behind them?

[He laughs] We have this little joke in the company: if somebody says something awkward, is not paying attention to the others, or makes a lot of noise, he or she is required to give a dollar for the piggy bank.

And to enforce that, others need to hold “a dollar” up and show their disapproval. I thought that the post-its we were using were not so cool (laughing), so I 3D printed dollar sign models for the team. Christmas was a good occasion to give them. Who does not like to get a free “dollar”?

What else did you build in the past?

Well, the biggest project that I ever made was a walking beam. The idea came while I was working for a company specialized in making machines for steel manufacturing.

A walking beam is a piece of equipment that allows raising and moving rolls of steel that can weigh 35 tons or more. The machine takes it from one “seat” and puts it on another. I thought of making a mechanical mock-up of such a walking beam: “Let’s have only three seats, and instead of a 35 tons steel roll, let’s take a wine cork and move it from one place to another. And the whole motion will be powered by a single lever.”

It took me quite a while to make the design. I experimented a lot with some open-source CAD tools—I didn’t know about Onshape at that time. My life could have been so much easier.

When the design was ready, I started 3D printing it. You might think that after the part is printed, you can simply use it. That is true for best quality industrial printers. The mere mortals often need to do some processing after the parts there are taken out of the printer.

You might need to make some filling or smoothing of the edges. That is part of the fun. And the satisfaction of having the machine working is great!

As a final thought, I could have done some stress analyses during the design phase since the machine gets jammed quite easily. Then again, I didn’t know about SimScale at that time.

Any plans for the future? What are you planning to build next?

The next project I would like to work on is a power divider in which every slot could be switched on and off separately. I find it quite annoying that whenever I have my charger put into a divider and have to switch on the whole thing, with my computer, laptop, printer all attached. I would feel better if they were not “under current”.

And another idea was inspired by an amazing light source developed by GravityLight. Their LED lamp is connected to a small dynamo, which is moved by a falling weight on a string, like in the old clocks. The lamp can run for 20-30 minutes. This is incredible when you think of using it—especially for places where there is no electricity or in some emergency cases. I would love to try 3D printing parts for a device like that.

What about 3D printers? Would you build another one?

Yes, definitely! It’s actually already planned, and this time I want it to be perfect.

If you would like to learn more about how to build a 3D printer with simulation, you can watch the recordings of the SimScale 3D Printer Workshop.