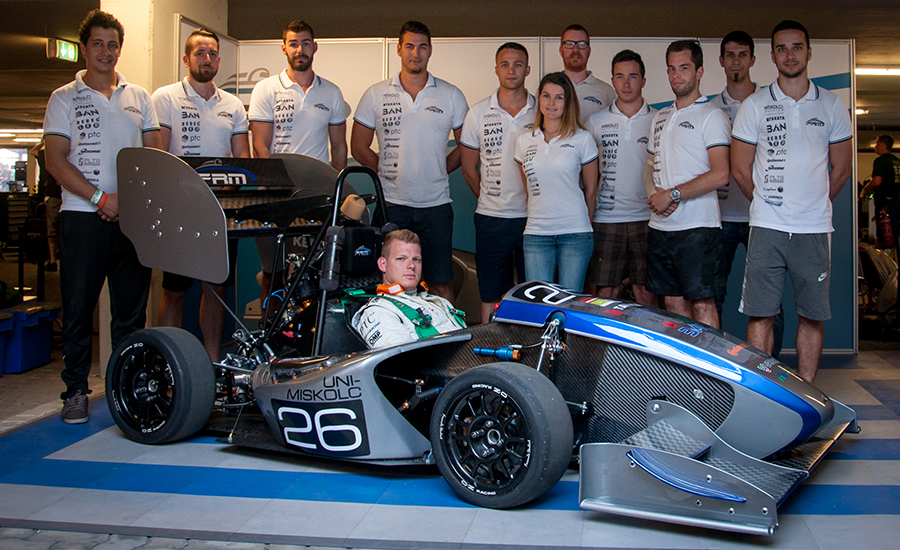

Formula Racing Miskolc is a student-organized Formula Student Team from the University of Miskolc in Hungary. Founded just 4 years ago, the team has already built three cars, with a constant focus on improving their design. This year, the team’s goal was to design an aero package for their 2017 vehicle, a first in the team’s history.

“We wanted to come up with a proper wing setup for downforce while avoiding excessive drag and maintaining a perfect aero balance between the front and rear tire contact patches. A secondary goal was to improve the previously existing car parts, which were suboptimal in terms of downforce,” explained Gábor Kinszki, a mechanical engineer student on the team.

Shortly after making the decision to design a full aero package, they saw a post about the SimScale workshop—Applications of CFD in Formula Student— on the Formula Student Germany Facebook page. This offered a great opportunity for the team to study CFD through structured lessons with experienced lecturers.

Using SimScale CFD for the aero package design, proved to be invaluable for the team, said Gábor. “We are a small team with a limited budget. We cannot afford real-world testing and prototype manufacturing; not to mention all the sensors and measurement tools, which would have been required by the project. We expected the CFD data to match the real-world values by about a 5-10% margin.”

The team faced several challenges along the way. One of the biggest was to produce an accurate, simplified model of the car that could be meshed. At the end of the day, the team overcame the challenges with a final design that was capable of generating 481N of downforce (sum of all vertical forces) at 20m/s, while maintaining a speed-independent (49.5% front and 50.5% rear) aerodynamic balance. The results also revealed that the team’s existing undertray design was working poorly. Furthermore, the team discovered that the side pods on the car, while they looked aesthetically pleasing, was generating excessive amounts of lift.

During the development process, the team used around 1,500 core hours’ worth of computing capacity, which is about 10 full car simulation runs. The longest simulation run took approximately 16.5 hours on 32 computing cores.

The team kicked the car into gear at the Formula Student Hungary Event, successfully completing the static and dynamic events.

As the team reconvenes back together to plan for the 2018 season, SimScale and CFD analysis will be a crucial part of their design process.

Formula Racing Miskolc is a SimScale Sponsored team. To learn more, visit the team’s website and keep up with them on Facebook and Instagram.

Discover all the simulation features provided by SimScale. Download the document below.