As electric vehicles (EVs) are quickly becoming the driving trend of the automotive industry today, one of the most debated topics is their battery efficiency and longevity. The EV battery market has been experiencing unprecedented growth, fuelled by the global push towards cleaner, more sustainable transportation [3]. As governments set ambitious targets for reducing carbon emissions and consumers become more environmentally conscious, the demand for EVs will continue to rise. This surge is driving advancements in battery technology, with a focus on increasing energy density, reducing charging times, ensuring effective cooling, and enhancing overall battery life. The market’s evolution is marked by rapid innovation, with major players investing heavily in research and development to create more efficient and cost-effective battery solutions.

The performance and durability of EV batteries are significantly influenced by how much they are kept from overheating. That’s why effective cooling systems are used to manage their thermal performance. Proper EV battery thermal management is essential for maintaining battery health, ensuring safety, and optimizing vehicle efficiency. This aspect crucially impacts the battery’s lifespan and the vehicle’s range.

SimScale, with its advanced thermal design analysis capabilities, emerges as a key player in the battery simulation software market. As a sophisticated cloud-native platform, SimScale empowers engineers and designers to analyze, simulate, and enhance EV battery cooling systems, addressing the complex thermal challenges of EV batteries and enabling the development of efficient and reliable solutions. Let’s take a look at how EV battery cooling can be done and what challenges stand in the way.

Understanding EV Battery Cooling

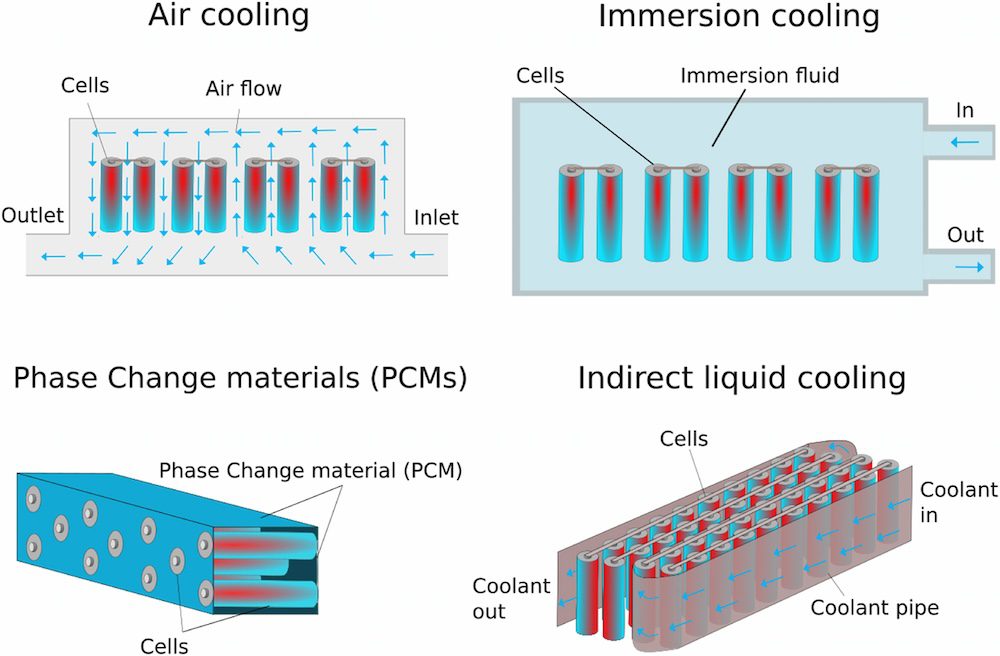

EV battery cooling is essential for regulating battery temperature to maintain efficiency and safety. Batteries generate heat during operation, which can reduce efficiency and lifespan and pose safety risks if not properly managed. Common cooling systems include:

- Air cooling: it uses fans to circulate air.

- Liquid cooling: it involves circulating particular types of coolant through the battery pack for more efficient heat dissipation.

How to Cool Down an EV Battery?

Cooling down an EV battery, especially during rapid charging or in high-demand scenarios, requires innovative strategies to handle intense heat generation. Key methods include:

Enhanced Air Cooling Systems: These systems use improved airflow techniques and advanced materials to increase heat dissipation efficiency.

- Advanced Liquid Cooling Solutions: More effective in managing high heat loads, these systems circulate coolant more efficiently and can be integrated directly with battery cells.

- Thermal Regulation Technologies: Incorporating smart sensors and control units that actively monitor and adjust the cooling process based on real-time battery temperature data.

- Phase-Change Materials: These materials absorb and release thermal energy to maintain consistent battery temperatures.

- Cold Plate Technology: Particularly effective in high-performance EVs, cold plates draw heat away from the battery cells more directly and efficiently.

Key Challenges in EV Battery Cooling

Thermal management of EV batteries still faces multifaceted challenges that impact battery performance and longevity. High heat dissipation during operations, particularly under fast-charging conditions, intensifies thermal management demands and can accelerate battery degradation if not managed properly. Cooling systems must also adapt to diverse environmental temperatures and balance efficiency with the constraints of space and weight. Additionally, the pressure to be cost-effective and sustainable necessitates innovative solutions for maintaining battery health and ensuring vehicle safety.

EV Battery Thermal Management: A Key to Sustainable EV Battery Design

EV battery thermal management goes beyond ensuring performance and safety; it plays a vital role in the sustainability of the entire EV ecosystem. Efficient cooling systems are integral to reducing the overall energy consumption of the vehicle, thereby decreasing its environmental impact. Better thermal regulation directly translates to less energy waste, prolonging battery life and reducing the frequency of battery replacements [2]. This is crucial in the context of environmental sustainability, as it minimizes the ecological footprint associated with battery production and disposal.

Efficient cooling systems play a pivotal role in enhancing the sustainability of EVs. By maintaining optimal operating temperatures, these systems ensure that batteries operate at peak efficiency, thereby conserving energy and extending the vehicle’s range. This efficiency is particularly important as the EV market grows, as it contributes to reducing the total energy demand of the transportation sector. Moreover, advancements in cooling technologies, such as the use of eco-friendly coolants and materials, further align EVs with environmental sustainability goals.

The Role of SimScale in EV Battery Cooling and Design

EV batteries are a highly competitive landscape, and the demand for innovative solutions in battery cooling is more pressing than ever. This is a domain where efficiency, safety, and performance intersect, necessitating advanced EV battery thermal management strategies. It’s within this challenging environment that SimScale enters the picture.

Offering a cloud-native engineering simulation platform, SimScale empowers professionals to tackle the complexities of EV battery cooling with highly accessible and scalable simulation capabilities. By utilizing SimScale’s thermal analysis, CFD, and structural analysis tools, engineers can experiment with and refine cooling system designs quickly and effectively all in a virtual space, accelerating the product development process and propelling the innovation of efficient and robust EV technologies.

SimScale offers a comprehensive suite of simulation capabilities based on multiple physics that can be run simultaneously all on one platform. Thanks to their cloud-native nature, SimScale’s simulation tools are not limited by hardware constraints or siloed workflows. On the contrary, they leverage the power of cloud computing to enable engineers to run as many simulations as they need in parallel with no delay. This shortens the simulation lead time and enables the use of simulation early in the design process, which in turn allows engineers to iterate faster and optimize their designs more efficiently.

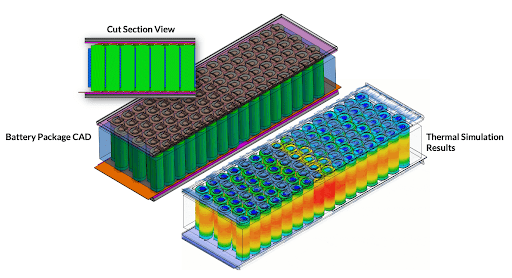

In the examples below, we take a look at how thermal simulation in SimScale is utilized to improve EV battery cooling.

Case Study 1: Thermal Simulation for High-Performance EV Components

In a case study featuring Rimac Automobili, SimScale’s thermal simulation capabilities were leveraged to enhance the design of high-performance EV components. The simulation focused on critical aspects like cooling efficiency and heat dissipation, which are paramount for the high-power electronic systems used in Rimac’s electric hypercars. This collaboration underscores the potential of cloud-native simulation to drive innovation in the design of high-performance EVs, ensuring both efficiency and reliability.

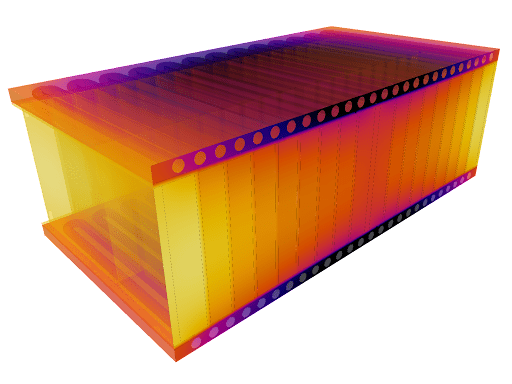

Case Study 2: Thermal Management Simulation of an EV Battery

An EV battery thermal management simulation case study involving Bold Valuable Technology showcases how they utilized SimScale to develop a high-end electric motorsport series battery. The team conducted over 100 simulations to analyze thermal behavior and coolant dynamics, significantly reducing the need for physical prototypes and experimental tests, thereby demonstrating the effectiveness and efficiency of using SimScale for EV battery cooling. Read more about this in our dedicated blog on Battery Thermal Management for Electric Vehicles.

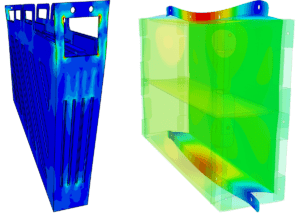

Case Study 3: Thermomechanical Simulation of an EV Battery

A thermochemical simulation case study on SimScale was conducted to assess the performance of EV Battery Pack Gap Fillers. Utilizing SimScale’s thermomechanical simulation capabilities, this comprehensive analysis covered aspects such as thermal conductivity and mechanical stresses, offering insights into how different gap filler materials and thicknesses affect battery temperatures and mechanical swelling. The study highlighted the critical role of material selection and design optimization in improving EV battery thermal management while ensuring mechanical robustness in EV battery packs.

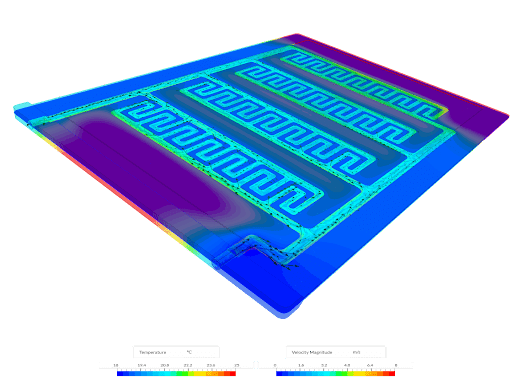

Case Study 4: Simulation and Optimization of an EV Battery Cooling Plate

Improving the design of EV battery cooling plates is crucial for optimizing battery performance, reliability, and lifecycle return on investment. This SimScale study simulated and optimized an EV battery cold plate design. The study involves several stages of simulation, including geometry setup, automatic meshing, and thermomechanical analysis. It focuses on fully coupled conjugate heat transfer (CHT) analysis and uses a Multi-purpose CFD solver for evaluating pressure-flow characteristics. The cloud-native simulations in SimScale allow for analyzing various scenarios, including geometric variants and different coolant flow rates, providing valuable insights into the design’s thermal and flow dynamics.

Case Study 5: Vibration Analysis Simulation of an EV Battery

Vibration analysis is crucial for EV batteries, as they are sensitive to shocks and vibrations, which can impact their performance and safety. That’s why it is crucial to analyze and optimize the structure of the battery to conform to standards and regulations. Using SimScale’s Finite Element Analysis (FEA) tools, the vibration of an EV battery was simulated, adhering to the UN 38.3 standard for safe transportation. It involves a virtual shaker table test, replicating the T3 standard, and covers setting up simulations within SimScale for modal and harmonic analysis, which is crucial for designing batteries that withstand various vibration conditions. This study is particularly useful for identifying potential resonance issues and optimizing battery structure before physical testing, thereby enhancing reliability and safety in real-world conditions.

The Future of EV Battery Cooling with SimScale

SimScale’s cloud-native simulation platform proves to be a valuable tool in advancing EV battery cooling and design. From thermomechanical analyses of gap fillers to optimizing cold plates and conducting vibration tests, SimScale enables a comprehensive understanding and enhancement of battery performance. Its efficient, cost-effective solutions demonstrate how cloud-native engineering simulation is pivotal in addressing the challenges and pushing the boundaries in the EV industry. To explore more of SimScale’s capabilities and how it can advance your EV battery cooling solutions, visit our product pages or simply sign up for free and let our team of experts support you with your analysis and design.

References

- Roe, C. et al. (2022). Immersion cooling for lithium-ion batteries – A review. Journal of Power Sources, 525, 231094

- Wang, Q. et al. (2015). Experimental investigation on EV battery cooling and heating by heat pipes. Applied Thermal Engineering, 88, 54-60.

- Zhao, G. et al. (2021). A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. Journal of Power Sources, 501, 23001.