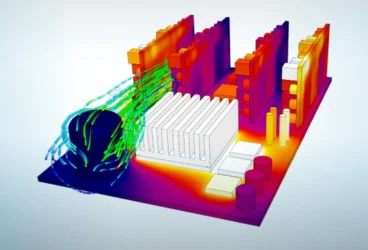

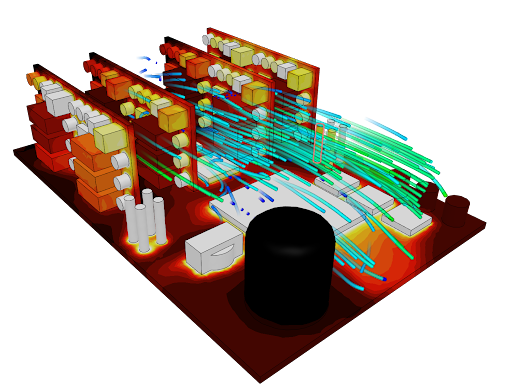

Thermal management is a critical step in electronics design for engineers designing reliable and safe products. Predicting temperature distribution across the product performance range of any device is a significant undertaking to develop fit-for-purpose products. Accurately predicting temperature distribution used to be considered a time-consuming and costly exercise that resulted in poorly understood thermal response in electronics products. We walk through the most common challenges faced by electronics designers and demonstrate how access to simulation at the early design stages is essential to achieving the required design performance, reducing physical prototyping costs, and increasing confidence in overall quality.

CAD & Geometry

In electronics cooling design, it is not uncommon to spend significant time preparing CAD models for simulation. Detailed production-ready models in their original state are likely to be unsuitable for most simulation tools, burdening simulation engineers with the tedious process of de-featuring geometry, simplifying parts, closing small gaps in the model, and fixing faulty geometry. And, in the case of geometry studies consisting of multiple variants of one base model, all this work often needs to be repeated. Traditional CAD tools in simulation software are, in many cases, inefficient or ill-equipped for such tasks, as they are primarily optimized for designing models from scratch, not simplifying existing models. The CAD mode feature available in the SimScale platform offers a set of purpose-built CAD editing and simplification tools. For example, the Flow Volume Extraction operation alleviates the engineer from laboriously isolating a flow volume as required in other pre-processing systems. Unlike traditional CAD systems, CAD mode focuses on a core set of simple, intuitive, but also versatile tools that are ideal in making CAD models simulation-ready.

This short demo video illustrates the power of CAD mode:

Electronics Design Performance

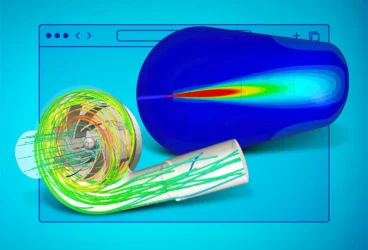

A common challenge in early-stage design is the lack of ability to quickly investigate and simulate design performance. Engineers want the capability to receive design feedback in an iterative manner using fast and accurate thermal and flow analyses applied to their designs. A lack of accessible engineering simulation at the early design stages can significantly reduce product performance. With SimScale’s full-stack solution, users can easily go from CAD import and edit to auto-meshing the model and post-processing in a few minutes, all from a web browser.

Test this project yourself here. Run time: 40 Minutes

Cost Reduction

Simulation tools that utilize cloud computing eliminate much of the costs associated with traditional simulation. They not only require no hardware installation or space for a workstation on-premise but are inherently scalable—enabling users to run multiple design iterations in parallel and deploy additional licenses organization-wide. The costs of traditional simulation stacks usually add up to big up-front investments before proving the added value of all the acquired hardware. With that also comes an enormous amount of responsibility in terms of maintaining the systems and a considerable know-how barrier requiring teams to conduct specialized training. Integrating cloud-native simulation into thermal management design also holds the potential for reducing enormous costs in the product development process. The more quickly a design study converges on its final version, the less costly it is. With simulation tools, designers can identify a problem before money is spent on producing physical prototypes. This is why Raycore Lights uses SimScale to shorten the design and prototype lifecycle of their products. In one example, Raycore ran a design study with eight simulations, each simulation taking five hours to complete.

Using legacy software, these would have been completed sequentially over a forty-hour period. With parallel simulation capabilities, all eight simulations were run concurrently, yielding a total simulation time of five hours.

Product Performance and Lifespan

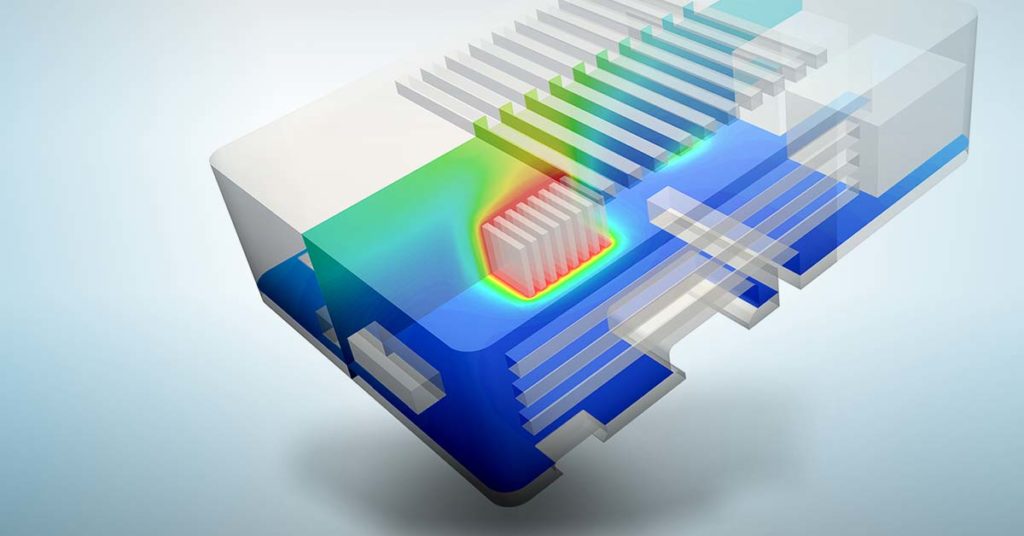

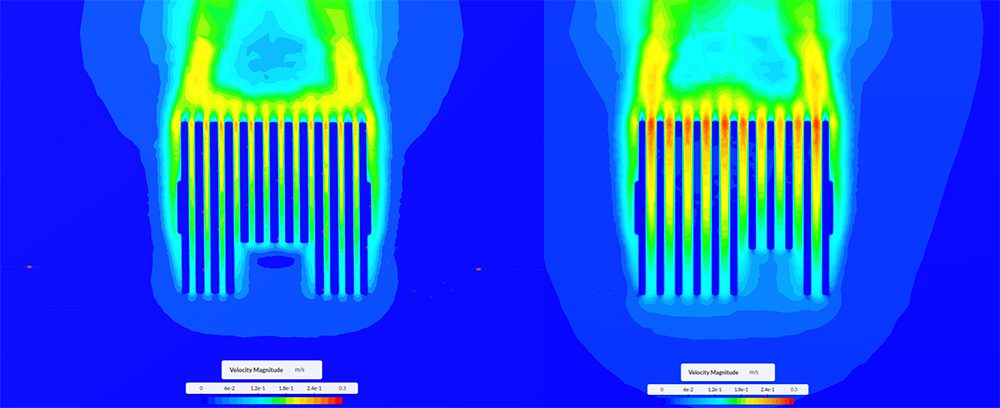

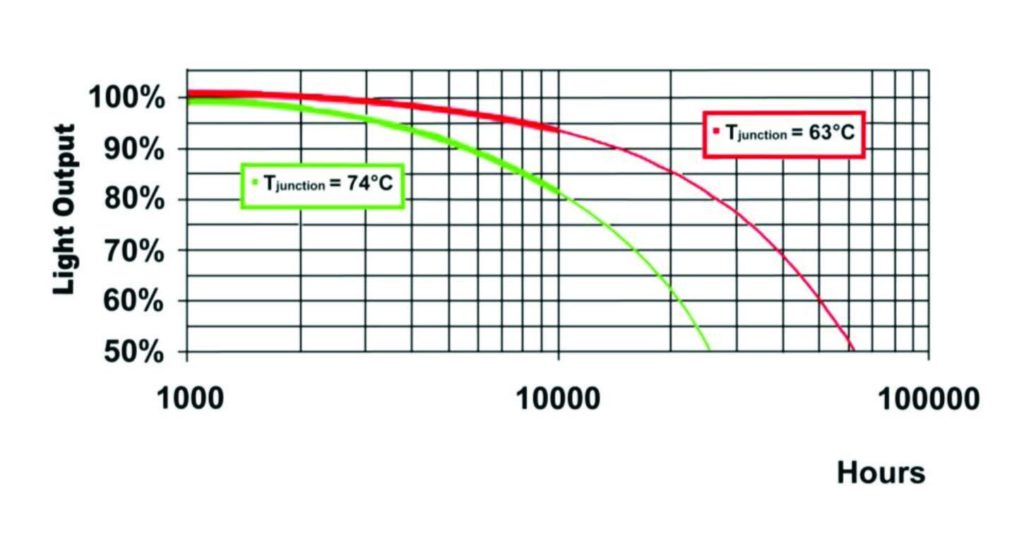

In the absence of the right cooling strategy, the lifespan of components can decrease and the respective electronic device will operate at a suboptimal level. Failure to effectively cool electronics can lead to loss of efficiency and even system malfunction. Therefore, high-performance microchips and electronic devices of all shapes, sizes, and levels of functionality need innovative thermal design techniques to maintain design operating conditions and remain within peak performance range. The life of LED systems, for example, shortens significantly when exposed to prolonged heat.

Following standardized physical testing procedures is expensive, time-consuming, and becomes prohibitive for each LED design. Using thermal simulation means that engineers can quickly evaluate the thermal performance of multiple LED designs at many operating points and use the results to predict component performance and lifespan.

Electronics Design with Simulation

A fully cloud-native simulation platform allows engineers to simulate and analyze high-fidelity models with complex physics by making High-Performance Computing (HPC) accessible, giving unprecedented accuracy in results, efficiency in design collaboration, and versatility in the vast range of electronics cooling applications that can be solved. Engineering managers rely on the accessibility of SimScale to provide their team with immediate access to electronics cooling digital prototyping, early in the design stage, throughout the entire R&D cycle, and across the entire enterprise.

Learn more in our whitepaper: Electronics Cooling Multiphysics Simulation