In this SimScale student success story blog, we speak with the Design Build Fly (DBF) team at UCLA about their remarkable transformation in aerodynamics using SimScale. This story shares how the Design Build Fly Student Team tackled challenges, their methods, and how SimScale made a big difference in improving their plane’s aerodynamics. Aiden answers some of our questions regarding their experience with the SimScale platform as a team.

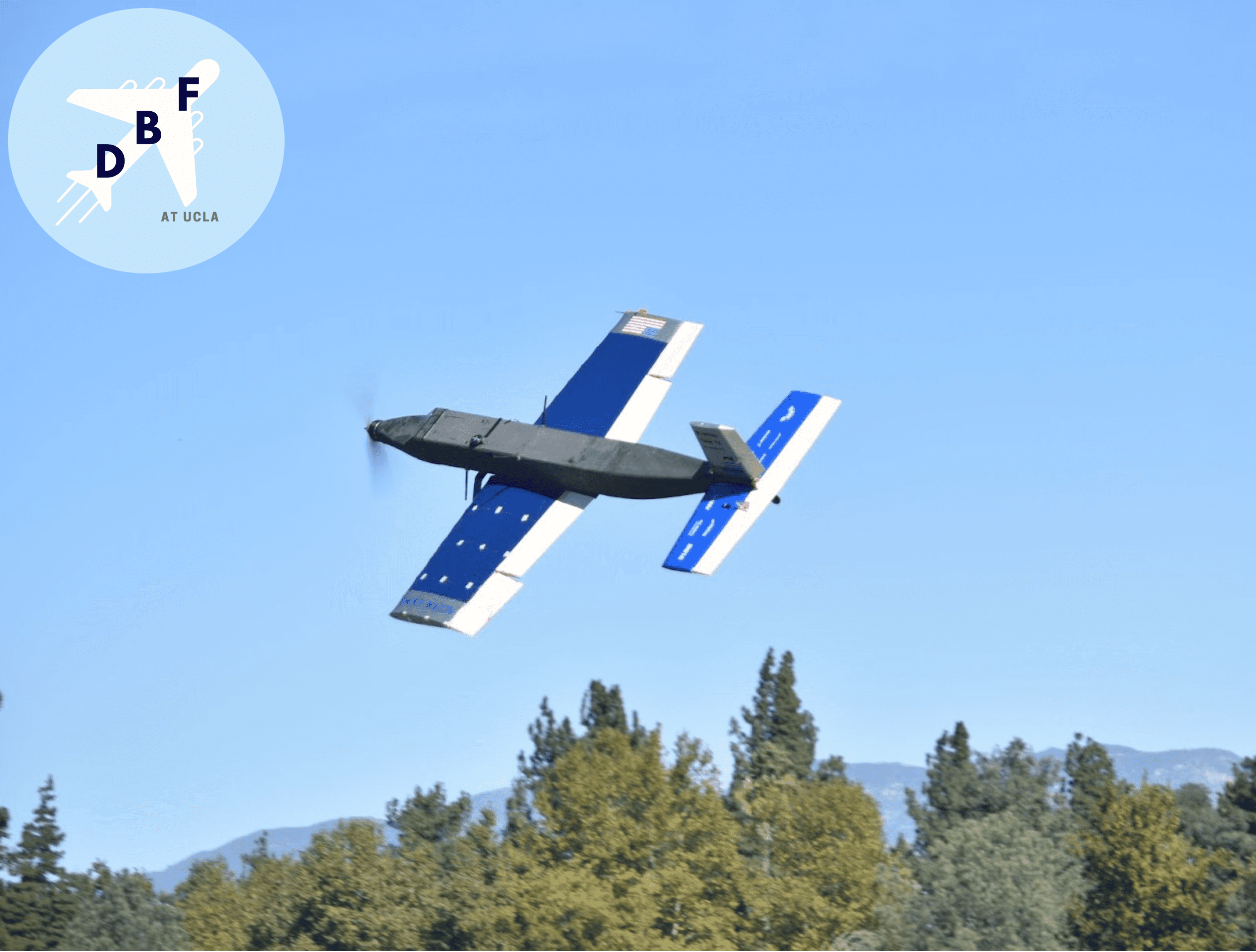

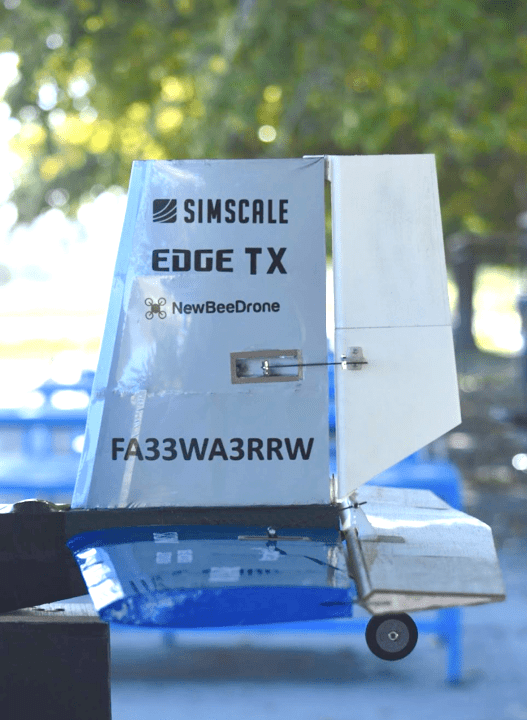

Design Build Fly (DBF) at UCLA, a team passionate about engineering, takes flight in the annual AIAA Design Build Fly competition, alongside 110 teams worldwide. Their mission involves crafting fixed-wing RC aircraft that master complex challenges such as carrying the longest possible wingtip-mounted antenna, delivering packages onto a section of the runway after each lap, or towing a banner. Despite their young talent, they landed 15th in the 2023 competition, hungry to soar even higher, aiming for a spot in the top 10.

“SimScale has changed our mindset in terms of CFD by allowing us to run significantly more simulations in significantly less time, and its cloud-based design has been a game-changer for teaching new members.”

– Aiden Taylor, Aerodynamics Lead (DBF)

The Design Build Fly team has a core of young and talented returning members who have experience in competition and are determined to improve. The rapidly growing team is hoping to push into the top 10 within the next couple of years.

Aircraft design involves tricky optimization issues. DBF at UCLA is dealing head-on with these issues as they refine their process to reach the top 10. This involves randomization scripts and genetic algorithms to optimize aircraft sizing and performance, vortex lattice models to determine stability, and detailed CFD analysis to optimize the form of the aircraft.

Prior to switching to SimScale, the team faced many computational and logistical issues. Most team members, as university students, used laptops for work. However, their laptops were slow for simulations with only about 6 CPU cores and 16-32 GB of RAM. This computational power could not even be fully dedicated to CFD, as university students often completed homework simultaneously on the same devices. Also, different devices and systems made it hard to work together because most CFD programs don’t run on both Windows and MacOS.

“SimScale is the CFD tool of choice for DBF at UCLA. It makes sharing and copying simulations easy, simplifying the process of teaching new members and reviewing their results. Since DBF at UCLA has adopted SimScale, the team has been able to run a much higher number of simulations in a short amount of time.”

– Aiden Taylor, Aerodynamics Lead (DBF)

To fix these problems, the team switched to SimScale at the start of the 2022-23 competition year. With SimScale, each student has received access to 16 cores in the cloud, more than what their laptops had. Simulations became available from any operating system simply through a web browser, and running them in the cloud made them faster and allowed multiple simulations at once, boosting the amount of analysis they could do.

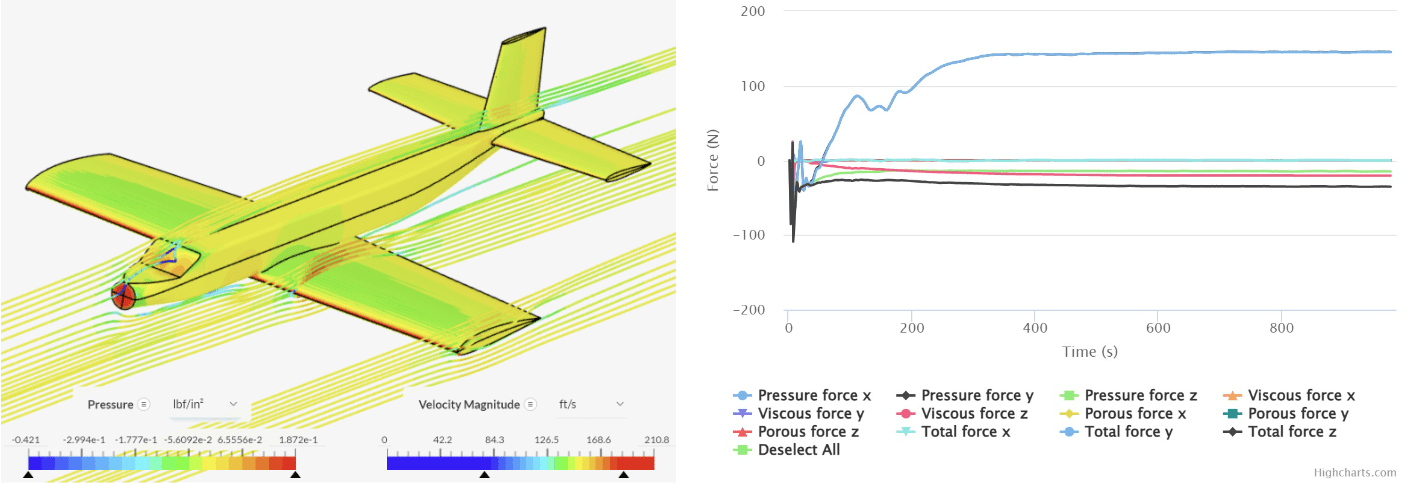

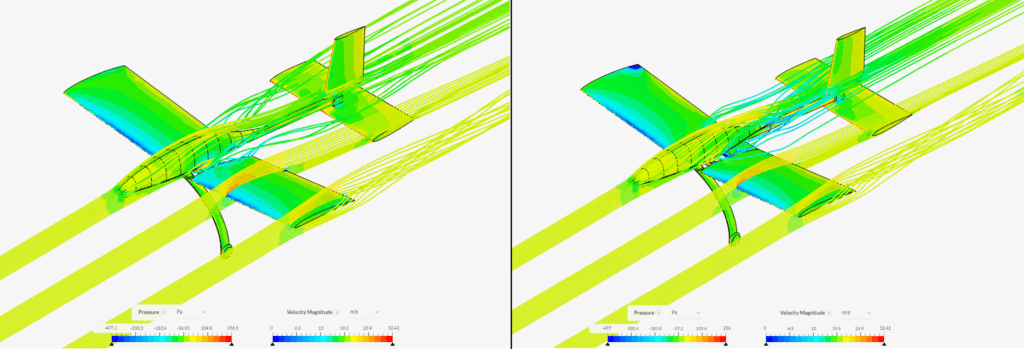

The Problem: Formation of Vortices at the Wing Root

Using SimScale for CFD analysis has led to significant performance benefits for DBF at UCLA. For example, during flight testing of a prototype of the 2022-23 aircraft, it was determined that significantly less lift was produced than was expected and that there was a lack of control authority from the tail surfaces. Incompressible CFD analysis in SimScale revealed that leaving a gap between the two removable sides of the wing, rather than having one continuous wing, resulted in vortices forming at the wing root. These vortices not only reduced lift due to high-pressure air leaking into the low-pressure region above the wing but also disturbed the airflow over most of the span of the tail surfaces.

“The CFD process has essentially been transformed from finding values for an existing design to an iterative process in which there is time to redesign parts multiple times based on CFD results. The team has also seen significant positive feedback from members regarding the learning process, as they are able to quickly share simulations, and they can access their work from any OS.”

– Aiden Taylor, Aerodynamics Lead (DBF)

How They Solved It: Adding a Wing Center Section and Improving Control

Based on the results from CFD, the team added a center section connecting the two halves of the wing in the region where it would not interfere with the landing gear. Post-processing results showed that the new center section of the wing significantly reduced the wing root vortices, causing cleaner flow over the tail surfaces, which resulted in better pitch and yaw authority. Furthermore, adding this lightweight component constructed of foam and carbon fiber resulted in an additional 4.62 lbf of lift at the aircraft’s cruise speed of 66 ft/s. This directly increased the team’s competition score by allowing the aircraft to carry more weight.

“We’re leveraging SimScale’s capacity to run multiple simulations concurrently in the cloud, enabling us to meet our simulation targets efficiently. Additionally, we’re sharing simulations with team members to adjust parameters and conduct similar studies with varying velocities or geometry.”

– Aiden Tayor, Aerodynamics Lead (DBF)

They’ve employed a Hex-dominant algorithm generating approximately 15 million nodes at a cost of around 30 core hours. Each simulation takes about 4 hours to run, at a cost of around 76 core hours. They examined the total lift and drag force produced by the entire aircraft, along with the specific lift and drag forces attributed to the wing, horizontal stabilizer, vertical stabilizer, and fuselage. Additionally, they gauged Cl and Cd. In certain simulations, they factored in lift and drag forces from other components, such as slotted flaps or landing gear wheel fairings.

Through ongoing refinement using the SimScale platform, they made impressive strides in their design and performance!

Next Steps for Design Build Fly

For the 2023-24 competition year, the team is going even more in-depth with their analysis. So far, they have run a number of design studies, including AoA sweeps at numerous air speeds to determine the lift and drag produced by the aircraft at different angles of attack, and to identify stall characteristics. Further analysis has been completed on the 2023-24 aircraft to test the effects of various subsystems. For example, the effect of endplates on the aircraft’s overall lift and drag has been determined during takeoff and cruise.

Another application of SimScale simulations to the 2023-24 DBF aircraft has been the optimization of wheel fairings to reduce drag caused by the landing gear. A series of designs were iteratively modeled in CAD and tested using CFD in SimScale. Compared to a wheel with no fairing, the wheel with the final iteration of fairing makes 60% less drag!

By constructing the fairings from a specialized lightweight, PLA plastic, the reduction in drag relative to the increase in weight is significant, justifying the addition of the fairings to the competition aircraft.

We’re confident that SimScale’s diverse simulation capabilities will greatly benefit the Design Build Fly Student team in upcoming endeavors, and we’re eager for future collaborations. If your team seeks academic sponsorship for optimizing your aircraft’s performance, whether for the AIAA Design Build Fly competition or any other competition – make sure to check out our Academic Plan for students who are joining design competitions.