Flow through rotating equipment is inherently unsteady. For example, pumps and compressors in HVAC and oil and gas applications experience pressure surges during start-up, shut-down, valve closures, and power fluctuations. Rotating machinery is regularly subjected to unsteady and destabilizing effects resulting from rotor-stator interactions, vortex shedding, and shock formations.

From a simulation perspective, steady-state methods like frozen rotor and mixing planes do not capture the true transient nature of such flows and are therefore less accurate in predicting the turbomachine’s performance, especially in off-design conditions. A full transient analysis that models the actual movement of the rotor and its interaction with stationary components becomes necessary in such situations.

Despite the limitations of steady-state methods, engineers and designers still heavily rely on them, either reserving transient analysis only for final stage prototyping when it may be difficult to make design changes, or completely skipping it. This trend is primarily driven by the disproportionately high computational requirements, long turnaround times, and workflow nuances of 3D transient simulations in traditional CAE tools. A transient run for a single data point could typically take a few days on a desktop workstation.

To bridge this gap, SimScale has developed cloud-native transient capabilities within its proprietary solver for rotating machinery, which yields converged results for a single data point as well as a parametric sweep in under 4 hours. Our technology employs the sliding mesh technique in a robust binary-tree mesher and high-order accurate RANS solver, which can handle incompressible as well as compressible flow. In this article, we present how the newest addition to our rotating equipment simulation technology paves the way for fast and accurate transient analysis early in the design stages of digital prototyping.

EBOOK

Cloud-Native Simulation for Industrial Machinery Manufacturing

Our latest eBook explores how cloud-native simulation is transforming the challenges of industrial machinery manufacturing into opportunities. Download it for free by clicking the button below.

Fast and Accurate

As the pioneer of cloud-native simulation, SimScale continues to perfect its cloud computing algorithms that make it possible to run transient simulations in a fraction of the time taken by traditional CAE. For example, a full transient simulation for a centrifugal pump on a mesh size of nearly 0.6 million cells takes under 20 minutes to complete. The same simulation in traditional CAE tools would take at least 12 hours or even a couple of days. Combined with the parametric studies capability that we launched in 2021, it is also now possible to obtain performance curves with the full transient physics included in nearly the same time as a single data point run.

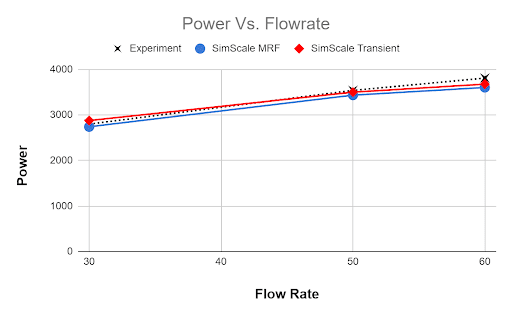

To establish the accuracy and reliability of the transient solution, we have validated the solver against a range of standard benchmark cases. Figure B below shows the comparison of power vs. flow rate for a centrifugal pump. The results from the transient analysis are a very good match with the experiment, closer than the steady-state MRF method. Mesh independence study for this case led to a mesh size of about 0.6 million cells and a full transient run for one flow rate took 18 minutes to complete.

Intuitive and Accessible

In traditional CFD software, getting the correct mesh arrangement across the sliding interface, and consequently, quality results from a transient analysis requires a high level of CFD expertise. Additionally, complex simulation workflows often frustrate designers and engineers, forcing them to devote more time to navigating software nuances than on iterating and perfecting their designs. SimScale is committed to breaking down the technical and economical barriers to advanced simulation. Our proprietary CFD technology for rotating machinery is built on the foundations of accessibility and ease of use, with the aim of enabling faster design iterations in a cost-effective manner. With the introduction of the advanced transient analysis capability, we continue to focus on features that allow greater automation and ease-of-use, including:

- Robust binary tree mesher that automatically generates optimal mesh interfaces between the rotating and stationary components

- Workflow parity between steady-state and transient analysis —using the transient approach is as simple as turning on a switch

- Real time visualization of results in the built-in post-processor

- Intuitive user interface with physics-based, predefined inputs

- Browser-based simulation that can be accessed, and collaboratively worked on, from anywhere in the world

Advanced Transient Analysis for Rotating Equipment

With the addition of the transient analysis capability in SimScale, it is now possible to include comprehensive physics in rotating equipment CFD and predict their effect on the component’s performance and wear and tear. Cloud-native implementation means that transient simulations in SimScale are orders of magnitude faster than in on-premise software.

Whether you are a pump engineer interested in analyzing vibrations due to flow pulsations, or a turbine designer optimizing the blade to reduce flow separation, cloud-native transient analysis capability offers you the advantage of super-fast design iterations, early in the design process and throughout the product’s life cycle. With SimScale, advanced transient analysis that was previously computationally expensive, time-consuming, or required expertise is now accessible via a browser, in a cloud-native platform that is scalable, easy to use, and cost-effective.

Learn more in our whitepaper: Simulating Turbomachinery Designs 10x Faster