Ventilation strategies have come under increased scrutiny since the COVID-19 pandemic began in December 2019. Many indoor spaces suffer from a lack of fresh air and poor indoor air quality which can impede productivity, cognition, and the general health and wellbeing of occupants. Access to flow and air quality simulation tools at the early stage of design can assist architects and engineers in testing various types of building and HVAC performance strategies. A computational fluid dynamics (CFD) tool with practically unlimited computing power and parallel simulation abilities for parametric modeling is required for accurate and rapid insight into ventilation equipment performance and the ability to assess multiple designs and products to arrive at the best ventilation solution. SimScale offers all of these features and works with many common CAD authoring tools such as Rhino®, Revit®, Sketchup, and AutoCAD®, making it convenient to import and edit even complex geometry.

SimScale users have access to hundreds of simulation models and templates in a public library that is a repository of knowledge learned on ventilation design assessments by a global user community. Lessons learned from these projects enable engineers to quickly and accurately predict wind and buoyancy-driven air movement using air quality simulation, and fresh air rates using natural ventilation simulation augmented with mixed-mode solutions. Here we will focus on insights into the performance of mixed-mode ventilation strategies in a classroom by simulating accurate representations of spaces, occupancy, internal gains, and equipment using a 3D CAD model, with multiple design variations for comparative analyses.

Cloud-Native Simulation for Industrial Machinery Manufacturing

Our latest eBook explores how cloud-native simulation is transforming the challenges of industrial machinery manufacturing (including HVAC) into opportunities. Download it for free by clicking the button below.

Workflow to Simulate Ventilation Equipment

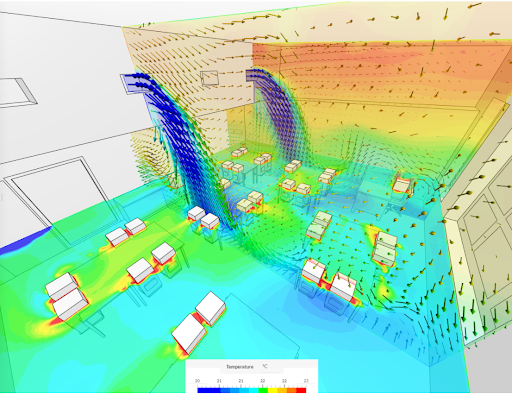

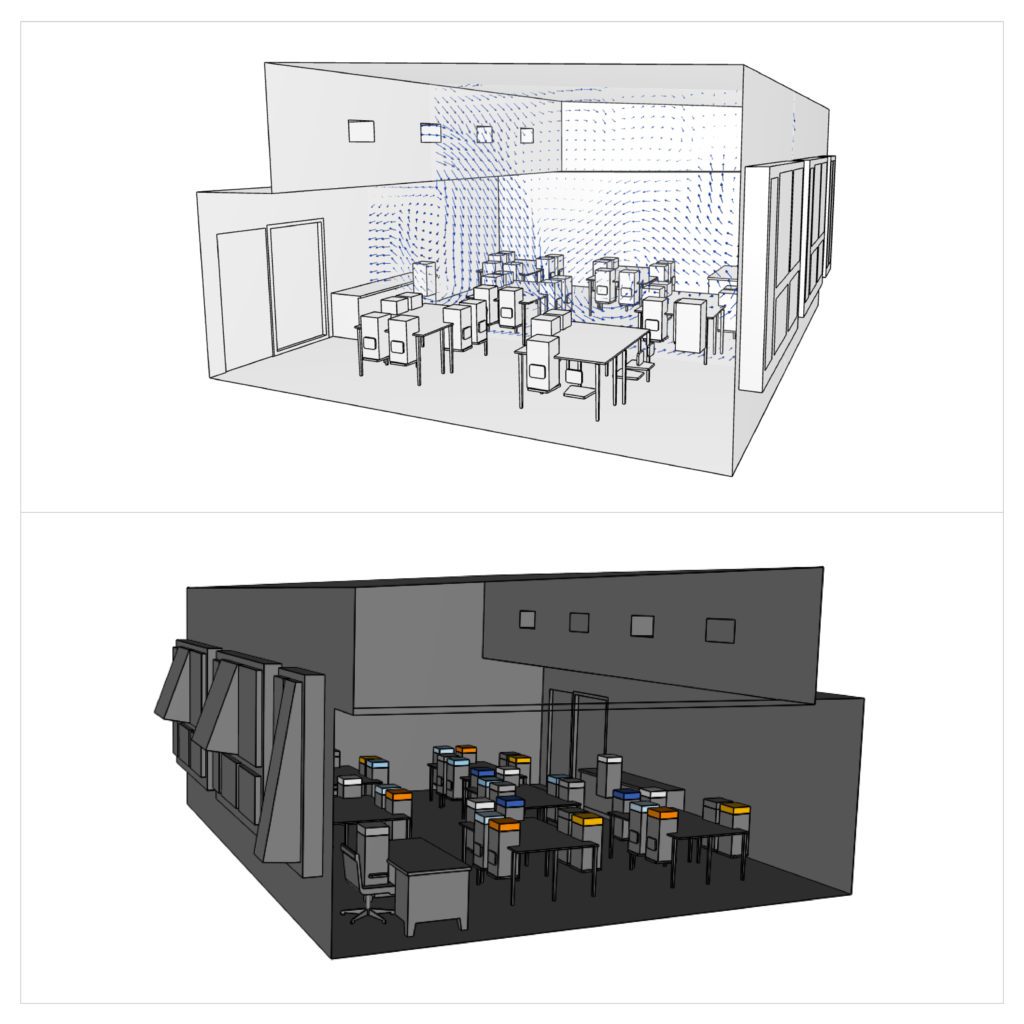

A 3D model of a classroom is shown in the below images. A parametric model is set up such that the floor area number of occupants can be changed easily. Internal loads (heat gains) are applied to each occupant using data from ASHRAE, LEED, and CIBSE guidelines. Additional heat gains are applied to represent low-power LED lighting and electrical equipment including laptops and a large screen display. Adventitious leakage is applied to the room at 0.1 (air changes per hour) ACH to reflect building infiltration from the outdoors, with an ambient temperature of 15℃. Air is selected from the extensive SimScale materials library for the indoor fluid and the walls have materials applied to them that reflect typical building fabric U-values for new school buildings in the UK. One of the facades has a series of windows with a top-hung style opening and opposite the windows on the inside, are four ventilation diffusers that can be set to supply, extract, or any intermediate combination. They can act as natural ventilation openings (passive) or have a velocity flow rate applied in either direction to represent supply and extract fans. A simple change in the boundary conditions offers the user a high degree of flexibility in evaluating multiple ventilation strategies.

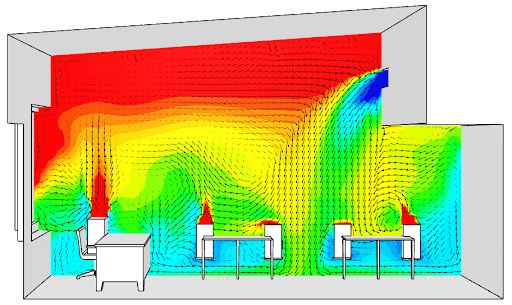

The convective heat transfer (CHT) analysis type is chosen and is ideal for internal room airflows where temperature effects must be captured. CHT allows natural convection (buoyancy and wind-driven flow) and forced convection (from fans or other devices) to be modeled and is considered a robust type of analysis for internal fluid domains, capturing the effects of density and gravity. Additionally, radiation can be simulated as well as a pollutant species represented by applying a diffusion coefficient, using the passive scalar approach. In this case, we are modeling CO2 in parts per million (ppm) as an indicator of indoor air quality. Outputs include internal temperature, velocity distributions, thermal comfort criteria, humidity, radiation loads, and more CO2 concentrations.

Using Simulation Outcome to Design Productive Learning Spaces

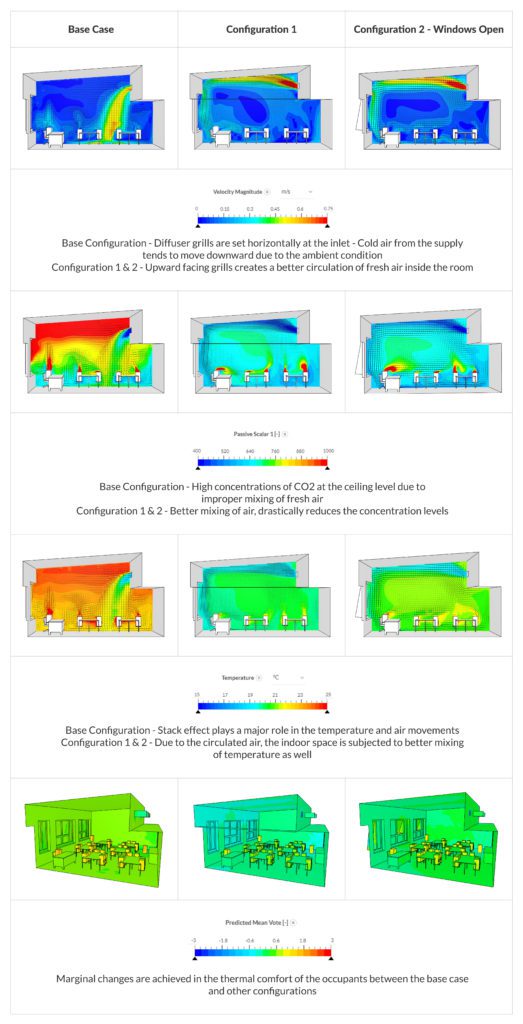

The classroom has three configurations that have been simulated and the results of various analyses are summarized in the table below:

- Base case scenario – supply air from horizontal diffusers only.

- Configuration 1 – supply air from a diffuser with upward-directed grilles for better air distribution

- Configuration 2– same as Configuration 2 and with the top-hung windows open

The base case scenario, although supplied with air, suffers from high heat gains and a build-up of CO2 due to a lack of mixing and ventilation. The diffuser grills are set horizontally at the inlet to the classroom and cold air from the supply tends to move downward due to the ambient conditions and creates an uncomfortable downdraught with poor ventilation efficacy. Configuration 1 and 2 have upward-facing grills at the diffuser, giving better circulation of fresh air inside the room. Similarly, with air quality, the base case configuration has high concentrations of CO2 at the ceiling level due to improper mixing of fresh air. Configuration 1 and 2 give better mixing that drastically reduces CO2 concentration levels.

Concerning indoor thermal comfort, the base case configuration is dominated by buoyancy-driven stack effects that direct temperature and air movement in the space. Due to the pressure distribution in the space and the downward fresh air supply from the horizontal diffusers, there is a stark lack of air movement. Configuration 1 and 2 offer better air circulation and the indoor space is subjected to better mixing of temperature. Configuration 2 offers better air mixing and quality using openable windows that introduce fresh air at lower ambient CO2 levels (400 ppm). Having the openable windows on the opposite side to the fresh air diffusers benefits from cross ventilation.

According to ASHRAE 55 and ISO 7730, the following are guidelines for indoor thermal comfort:

- For Predicted Mean Vote (PMV):

- ASHRAE 55

- -0.5 < PMV < +0.5

- ISO 7730

- -2 < PMV < +0.7 (Limits)

- -0.7 < PMV < +0.7 (Existing Buildings)

- -0.5 < PMV < +0.5 (New buildings)

- ASHRAE 55

- For Percentage of People Dissatisfied (PPD):

- 5% < PPD < 100% – depending on the calculated PMV

- To comply with standards → no point in the room should be above 20 % PPD

Marginal changes are achieved in the thermal comfort of occupants between the base case and other configurations using the predicted mean vote (PMV) measure. Our classroom is generally between -0.6 and +0.6 in PMV. Although thermal comfort is not the focus of this exercise, improving the PMV further can be accomplished using better fabric thermal performance values and lowering the supply inlet temperature, for example. Users can also simulate a heat recovery option in the case of extracted flow through a heat exchanger device.

Further Air Quality Insights

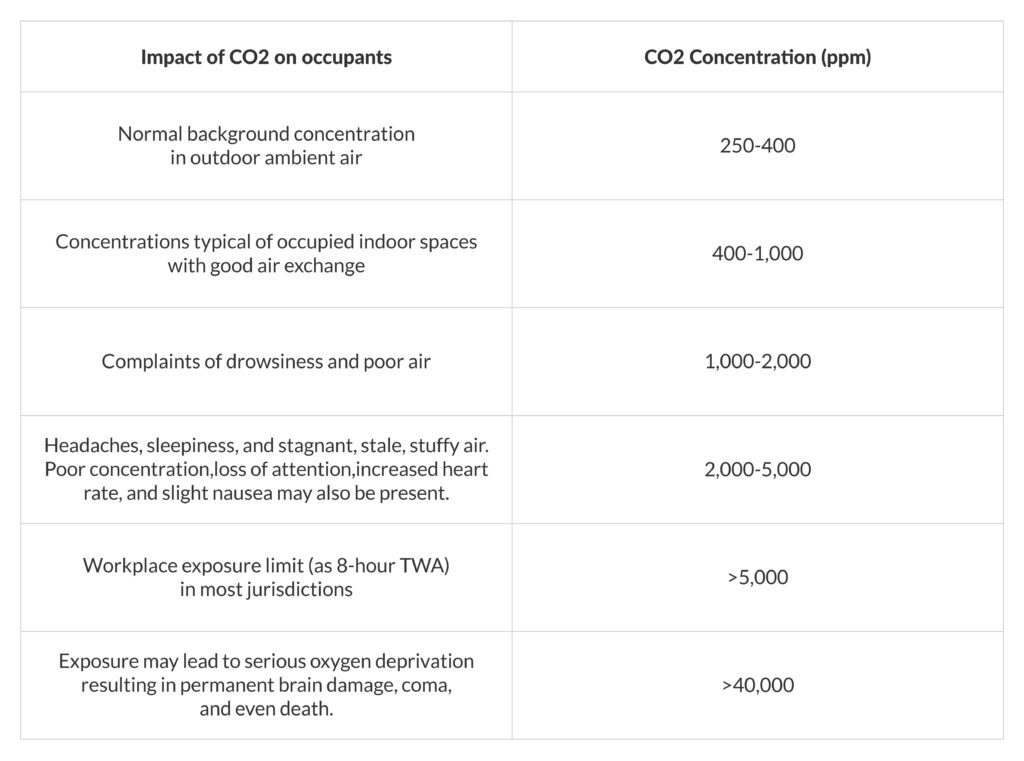

Let’s take a closer look at air quality. High levels of CO2 in classrooms and learning spaces have been linked to decreased cognition and exam scores. This is a widely published area of study. Similar patterns are seen in the productivity of workers in office spaces. Common guidelines for acceptable CO2 concentrations are given below. Classrooms should be less than 1000 ppm in controlled ventilation spaces. Some building regulations allow CO2 concentrations of 1000-1500 ppm where solely natural ventilation is used, although recent trends have favored mixed-mode ventilation in schools to provide better air quality and thermal comfort.

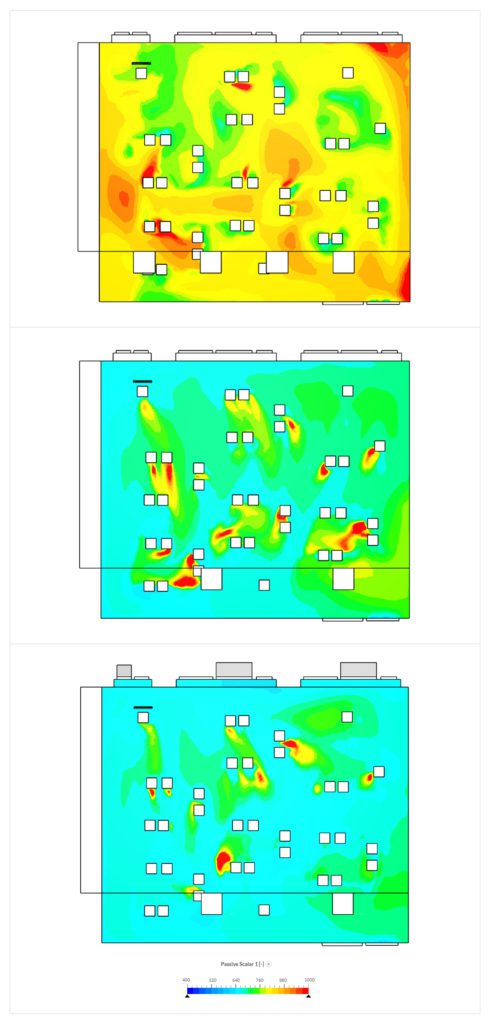

The following images show horizontal slices taken at occupant head height (seated) in the classroom and are colored by CO2 concentration, followed by a vertical slice showing the same. The CO2 source is applied at the head of each occupant. Configuration 2 has the best air quality performance and shows 22% less CO2 in ppm than Configuration 1. Opening windows makes a significant difference by benefiting from fresh air with a low CO2 concentration, better mixing in the room, and cross ventilation. The CFD simulation shows us the spatial distribution of CO2 that can be used for identifying areas of stagnant and stale air. It is also useful to guide the placement of CO2 and other environmental sensors. Spatial level detail from CFD is a major compliment to common energy/thermal modeling tools that designers use which are limited to time-series analysis of one point (node) in the center of the room (thermal zone). Using CFD and thermal models together can give better insights to architects and engineers who are trying to optimize a complex design brief including minimizing energy consumption whilst attaining strict air quality, fresh air, and thermal comfort requirements.

Simulating Ventilation Equipment with SimScale

We have shown how building openings have been parametrically studied to alter internal fresh air supply and air quality thresholds using fluid flow and thermal analysis types in the SimScale platform. With SimScale, users have access to powerful and fast simulation features specifically for analyzing thermal comfort, indoor air quality, and their influences.

“The SimScale platform has allowed us to develop and test scenarios including ventilation flow paths and understanding the dynamics between building fabric, airtightness, window natural ventilation design, and CO2 concentrations in various utilization scenarios. The platform has given us quality, visually digestible output to inform decision-making and to compare results against our monitored data from our extensive post-occupancy studies. Working with SimScale has allowed us to study our learning spaces in a way we never have before. It has helped inform us on which design strategies may provide the biggest impact on performance.”

— Robert White, Technical Associate and CEPH Designer at Architype

Get an even better understanding of CFD simulation for simulating ventilation equipment and airflow with our on-demand webinar with ASHRAE. Our specialists teach techniques that enable engineers to quickly predict wind and buoyancy-driven air movement, air quality, and fresh air rates using high-fidelity engineering simulation: