“Ride Faster, With Less Effort, and Enjoy Your Cycling More.” This is the promise the people at Tokyowheel make to their customers. And they stand by their word.

Seven years ago, carbon carbon fiber wheels for bikes were reserved only for the rich in Japan, as the price for a decent set was no less than a few thousand dollars. However, Tokyowheel’s founder, James Ferrer, set his mind to change this and give cyclists the access they wanted to high performance carbon wheels that were realistically priced. With this clear goal in mind, he began to import and distribute a brand of wheels made in the USA and open a small wheel building factory in Tokyo to improve them and enable customers to customize their orders.

Things don’t usually go as planned, and due to family problems, James was forced to move back to the USA and adapt his business model to be able to work remotely. From a distributing company, Tokyowheel became a producer, collaborating with the best manufacturing partners worldwide and expanding its sales outside of Japan. In no time, Tokyowheel’s Epic and Elite wheels were being sold in 49 countries by 2014.

In the three years since, the company’s products have continued to improve and new versions brought to market. Today, Tokyowheel sells in 69 countries and has staff on 4 continents.

Together with the expansion, making use of technology to design significantly better products with every launch becomes compulsory in order to stay competitive. It’s no wonder the company integrated engineering simulation into its design process. Simulation’s main benefit is that it enables the analysis of different design variations from the beginning, thus allowing modifications and iterations in a few hours or days, compared to the weeks or even months involved in creating physical prototypes.

To ensure that the wheels were aerodynamic, the company’s team performed fluid flow analyses of strategically different wheel designs in parallel. The reason they chose SimScale as their simulation software was to reduce the design time and also the costs, as the traditional software requires you a dedicated workstation without the possibility of working remotely. It also implies much higher costs.

How Did the Carbon Wheels Simulations Work?

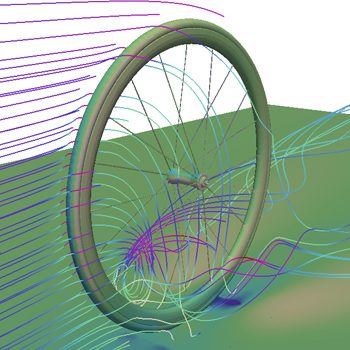

After producing a CAD model of the carbon wheel along with an MRF domain, the geometries were uploaded into the SimScale platform for meshing. In essence, a virtual wind tunnel was set up to mimic the real-world cycling environment. The domain contained a moving floor and the wheel’s geometry. The wheel was then rotated about its axis with an angular velocity that matched the tangential velocity of the floor. The inlet air speed entering the wind tunnel was set to match these conditions.

“In the end, the simulations performed excellently! We compared the drag numbers and surface data generated by SimScale to those generated by other CFD packages and found a higher degree of accuracy and detail. We ran around 10 different simulations to generate the most accurate data we could,” said Joel Cy Scott, Lead Engineer at Tokyowheel.

The simulations were 30 minutes long on average, using 16 cores. Ultimately, the engineers at Tokyowheel obtained drag force values on both the axis of travel and the perpendicular axis. The resultant data was crucial for the determination of the most aerodynamic carbon wheel profile. After testing multiple designs, they were able to move forward in an iterative way and converge on a significantly more aerodynamic wheel design. All the details are available in the official case study.

“Our next steps will be completely iterative as we test more and more rim profiles, at different yaw angles, and compare the data. The results of our CFD simulations direct much of the design and manufacturing process. We will also be comparing our CFD results to wind tunnel data during the later stages of development, in addition to testing the designs with real cyclists on the road. We are confident the improvements that the CFD simulations have provided will result in a significant benefit to our customers’ cycling performance,” concluded Joel.

Why is SimScale so Flexible?

The reason why SimScale can provide such a low price and flexibility compared to any on-premises simulation software is the fact that it works 100% in the Cloud. The engineers at Tokyowheel could perform the online simulations from normal PCs or laptops, and had the opportunity to collaborate on the same project, analyze the design, quickly implement the changes in CAD software based on the CFD analyses, and immediately test the new versions in SimScale, which ultimately resulted in a better final product.

A local computer-based system would have severely limited the number of design experiments that could have been run in the given time period. And here’s the best part: once you set up and run your simulation, you can just close your computer and come back in a few minutes or hours (depending on the simulations’ complexity), to see your results.

If you want to give SimScale a try, sign up for a free community account.

And if you’re interested in a unique biking experience, Tokyowheel delivers for free worldwide. Talk about an international company!

Discover all the simulation features provided by SimScale. Download the document below.