Unfortunately, the Brunel UAS team is no longer active. We’re keeping this post public for informational purposes due to the project being interesting. We wish the team all the best for the future.

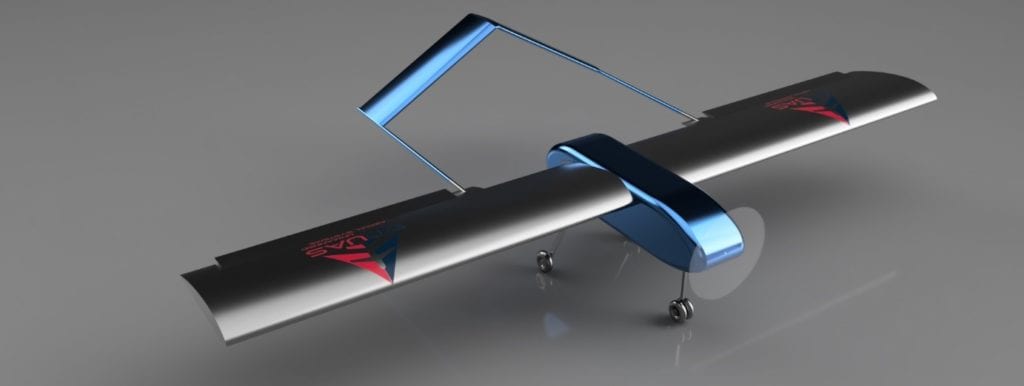

Brunel Unmanned Aerial Systems recently formed a student-led team, focusing on design, development, manufacture, and eventual demonstration of a novel unmanned aerial system for participation in the IMechE’s UAS Challenge 2020. Brunel University initially participated in the competition in 2018/19, with this year’s entry attempting to build on the successes of the previous years.

The project was primarily completed academically, led by a core team of 9 masters students and 5 undergraduate students. Brunel Unmanned Aerial Systems was further developed as a University society with a keen membership of multidisciplinary students to promote and engage interest and understanding of unmanned aerial systems.

The IMechE’s UAS Challenge 2020

IMechE‘s (Institution of Mechanical Engineers) Unmanned Aerial Systems Challenge 2020 is an annual and industrially recognized competition to promote the engineering sector as a whole, and the professional development of engineering students.

IMechE’s UAS Challenge Requirements

The challenge requirements necessitated design, fabrication, testing, and demonstration of a novel unmanned aerial system (UAS) conforming to strict competition regulations and national airworthiness requirements (CAP-722). Despite primarily focusing on the development of an aircraft for participation in an academic competition, project completion sought to demonstrate the commercial viability of UAS application for humanitarian aid mission specifications. Aircraft development specifically focused on the maximization of payload capacity (for autonomous aid delivery) and search and rescue functionality, while ensuring ease of deployment, maintenance, and operation alongside low development cost.

The Task: Optimizing Aerodynamic Performance of a UAS

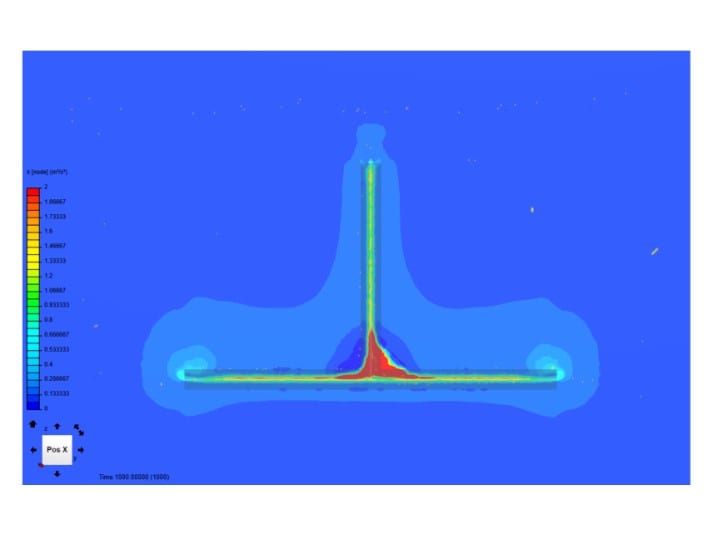

Brunel Unmanned Aerial Systems utilized SimScale to investigate and optimize the aerodynamic performance of the wing/fuselage structure, while simultaneously assessing the stabilizing performance of an inverted v-tail empennage. Competition requirements for increased payload capacity and conformance to maximum take-off mass criteria (6.9Kg) necessitated the maximization of aerodynamic performance to permit minimization of structural mass.

The selection of an environmentally-friendly electric propulsion system required further minimization of aircraft drag to ensure the aircraft designed provided appropriate range capabilities. The design and optimization of the empennage structure-maintained requirements for mass and drag minimization. It also introduced demand for appropriate longitudinal and lateral responses, characterizing static and dynamic stability while facilitating effective control authority. Requirements for solely autonomous aircraft function further enhanced requirements for aircraft stability.

Brunel Unmanned Aerial Systems Incorporates CAE: Challenges & Benefits

Incorporation of computer-aided engineering (CAE) within the early design phases permitted a rapid, low-cost assessment of conceptual designs, while facilitating optimization tasks through the removal of time-consuming model manufacturing processes. In previous years, CAE significantly shortened the lead time for the aerodynamic development of the aircraft, which was particularly beneficial given the short time frame of the competition.

Brunel Unmanned Aerial Systems: Challenges Faced Prior to CAE

Limited access to appropriately scaled wind tunnel facilities on campus initially restricted the aerodynamic development of the aircraft, while the manufacture of appropriate models for testing introduced significant financial costs and time penalties. Optimization tasks were further restricted through the limited capacity for aerodynamic assessment with primary analysis techniques centered around derived data from force balances. Alternative simulation software was available on campus with limited mesh sizes (academic licenses) and access limited to college opening hours.

Brunel Unmanned Aerial Systems: Expected Benefits of CAE

The anticipated benefits of CAE included enhanced understanding of the aircraft aerodynamic performance throughout a representative flight envelope, including yaw conditions (which proved challenging to replicate effectively in the wind tunnel). Further expected benefits from a rapid assessment of the aircraft performance included simultaneous development and continuous assessment of the propulsion system, as well as the continuous design of the flight control system (where various performance inputs were required).

The primary benefits of CAE incorporation involved significantly improving confidence in results, especially when validated against a wind tunnel model. Enhanced confidence in results would permit the selection of appropriate timings to progress to manufacturing stages, potentially reducing the risk of failure and overall project costs.

Further non-technical advantages included opportunities for students to interact with professional-level CAE software from SimScale, facilitating the development as well as gaining an understanding of computational analysis techniques.

Brunel Unmanned Aerial Systems’ Expected Results from SimScale

The team anticipated that SimScale would provide a platform for the comprehensive aerodynamic development of the unmanned aerial vehicle while providing adequate output for further structural and stability analysis. Data from CFD was to be further applied in simulation and development of the flight control systems with results presenting opportunities for confidence development before progression to prototyping and flight testing (reducing overall project cost).

The team was particularly interested in the online accessibility functionality, facilitating continued project work outside of University opening hours. Several members of the team had significant commutes, with SimScale allowing work from home and easy sharing of simulation and results. Throughout the early stages of the Covid-19 pandemic, SimScale proved to be invaluable for the team, allowing continued and uninterrupted work on the project.

This paper addresses the difference between on-premises software and SaaS

solutions for computer-aided engineering, explaining how SaaS came to be and its

key benefits for students and professionals alike.

Without access to SimScale, the team would have lost approximately 4 weeks of development, at a critical project phase, as alternative arrangements and remote access to various hardware and facilities were arranged. SimScale further mitigated significant downstream delays on other team members work with dependency on CFD results. The team expected a challenge when working with the SimScale platform, having limited nonacademic exposure to professional engineering software; however, SimScale support and the online community ensured the team was able to learn and progress quickly to support the ambitiously short project timeline.

When Did Brunel Unmanned Aerial Systems Begin To Use SimScale?

SimScale had previously been incorporated by the Brunel Unmanned Aerial Systems team for completion of the 2019 iteration of the IMechE Unmanned Aerial Systems competition. Initial validation exercises undertaken by the previous team (2018/19) demonstrated SimScale’s accuracy and validity against a range of commercially available alternatives. SimScale was proven superior due its online functionality, permitting remote and out of college hours access to high power computing capabilities. SimScale’s comprehensive online community forum presented further benefits for learning about the CAE platform and enhancing understanding of its capabilities.

Initial CAE Challenges & How The Team Overcame Them

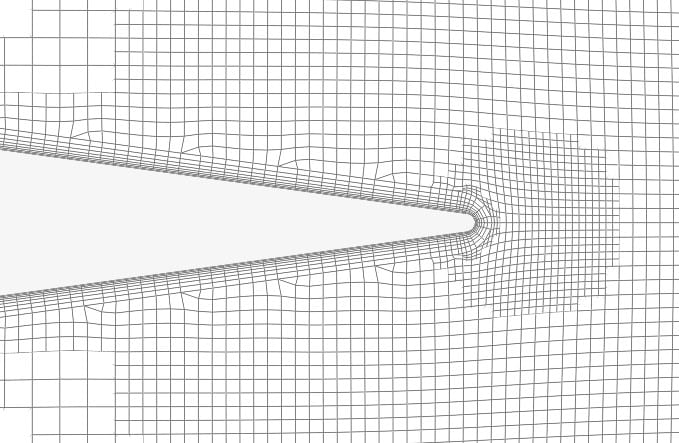

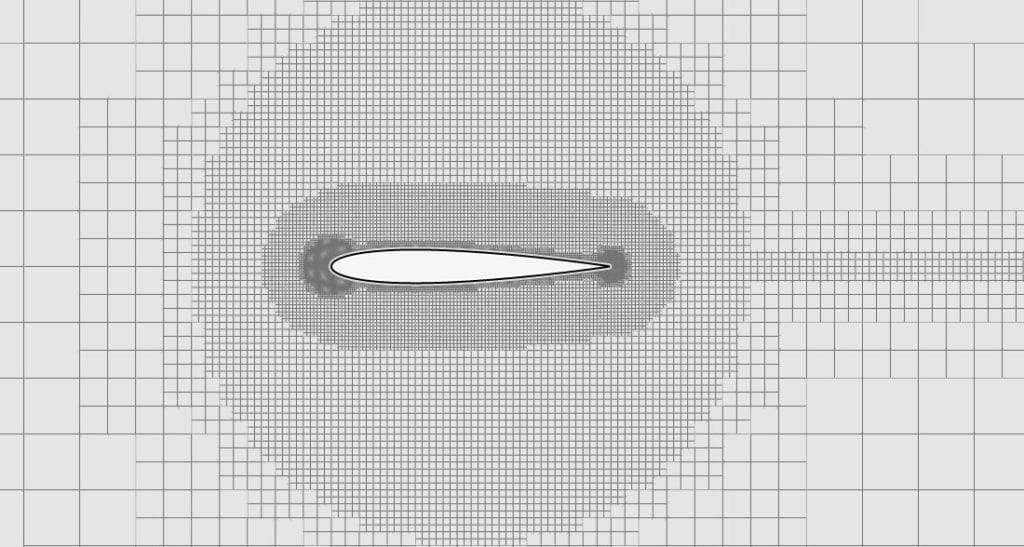

The development of initial meshes for simple geometries utilizing hex-dominant parametric methods prompted the application of this method for further mesh generation. Increased complexity geometries introduced challenges for the generation of a resolved boundary layer with acceptable aspect ratios. Large investments in computational resources were made to ensure the generation of effective meshes (especially throughout mesh refinement activities).

The problem was overcome through a significant investigation of the community-led forum and kind support from SimScale. The forum presented opportunities to witness solutions found by other users with similar problems; however, variations to applications meant some solutions were not always effective or applicable. Support from SimScale was comprehensive and wherever possible, time was invested to educate and progress our understanding of the problem on top of assisting with resolving the issue in hand. Combined assistance from both streams proved invaluable in the effective completion of this project.

Simulation Setup

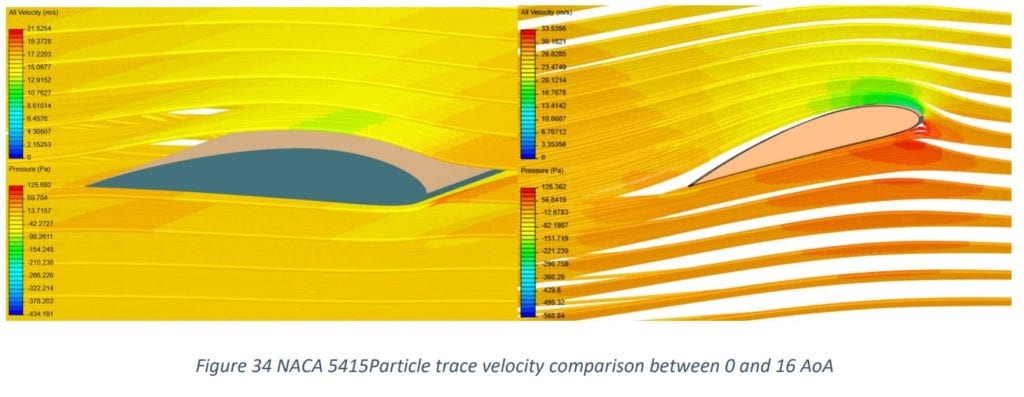

Initial simulations were completed in tandem with physical wind tunnel experiments, and panel method analysis techniques to ensure numerical model validity. Results were further compared with previous research undertaken by the team to ensure viability for further analysis. Inlet-outlet conditions were applied to permit universal domain application for investigation of aerodynamic response throughout pitch and sideslip conditions, facilitating comprehensive stability analysis, while symmetry was utilized where possible to minimize simulation cost. Aerodynamic performance result controls were implemented for rapid assessment; however, probe points were applied to permit direct comparison against any pressure tapped wind tunnel experiments.

Mitigation of mesh discretization errors dictated completion of mesh sensitivity studies, considering factors including leading/trailing edge, wake, and aerofoil surface refinement. Boundary layer refinement was applied to permit full resolution of the boundary layer as opposed to alternative wall functions, presenting significantly enhanced approximations of aerodynamic response.

Meshing

Three-dimensional unstructured meshes were generated utilizing SimScale’s Hex-Dominant Parametric function, facilitating the rapid generation of high-quality hex-dominant meshes with effective boundary layer refinement using OpenFoam’s “SnappyHexMesh” tool.

Where possible, some three-dimensional meshes were extracted and extruded utilizing OpenFoam through Ubuntu. Effective extrusion to two-dimensional meshes permitted a significant reduction in computational costs, while presenting significantly accurate approximations of two-dimensional finite wing aerodynamic performance. Most meshes for three-dimensional investigation were generated utilizing the Hex-Dominant method.

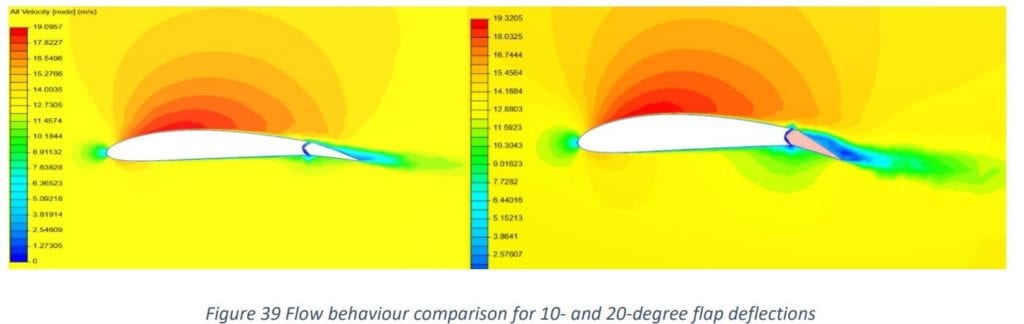

Simulation Type

Simulations utilized the incompressible k-ω Shear Stress Transport (SST) throughout, facilitating the effective cost-efficient resolution of the turbulent flow properties. The selection of the shear stress transport model reduced result sensitivity to inlet freestream turbulence conditions. K-ω models were found to produce accurate results within adverse pressure gradients and flow separation compared to the alternative models investigated. Turbulence intensity was approximated from known values for the wind tunnel utilized in initial validation experiments.

Aerodynamic performance result controls were implemented for rapid assessment; however, probe points were applied to permit direct comparison against any pressure tapped wind tunnel experiments.

Simulation Execution, Performance & Results

The team ran approximately 300 simulations using their 2 student accounts. Each simulation was approximately 2.5-3 hours, varying between 16 and 32 cores.

Initial numerical model development yielded results closely aligned with wind tunnel experimentation and panel method analysis. Simulations undertaken performed effectively, converging appropriately, and presenting acceptable results for downstream analysis. Unfortunately, downstream wind tunnel testing was not available (due to unforeseen global mitigating circumstances) to validate final results; however, panel method analysis and simplified investigation of overall aircraft stability performance demonstrated alignment of anticipated results.

Results obtained primarily focused on the investigation and optimization of aerodynamic performance throughout the flight envelope to match initial predictions obtained throughout conceptual design procedures. Results obtained effectively aligned with requirements for the aircraft outlined by conceptual design software. Particular aerodynamic efficiency gains were obtained through optimization of the inverted v-tail, with resulting reductions in size, alteration of dihedral angle, and introduction of Hoerner style wingtips, resulting in zero-lift drag reductions of up to 28% relative to the initial configuration investigated.

“SimScale presented a challenging and exciting platform to learn and apply for the development of our unmanned aerial system. The platform proved user-friendly and the tutorials available assisted with learning it quickly and effectively. The team at SimScale and the community forum were extremely friendly and supportive and always keen to assist where possible to not only ensure the success of the project but further develop the team’s understanding of CAE. Throughout our relatively short time working with SimScale, we were informed of several new features being implemented and a community board to suggest new functionality. We have really enjoyed the opportunity to engage with SimScale.”

Thomas Hulatt

Brunel Unmanned Aerial Systems ROI, Results & Next Steps

Isolated analysis of the wing/fuselage and empennage structures utilizing CAE demonstrated successful attainment of aerodynamic targets outlined through conceptual design procedures, while minimizing overall aircraft drag. Aerodynamic performance facilitated the generation of a viable and stable aircraft platform with minimized power requirements. Blank paper development of a novel aircraft combined with prohibitive global circumstances ensured successful aircraft development could be primarily attributed to computational work undertaken using SimScale.

The team’s application of SimScale has facilitated optimization activities previously found challenging when merely utilizing experimental methods. Less technical benefits of SimScale have included the ability to operate the platform from any computer with an Internet connection, allowing the team to work remotely and present findings in meetings away from the university’s computational facilities. This has further permitted completion of simulations overnight and in hours where the university facilities would be closed. The unforeseen closure of the university would have otherwise prohibited completion of the aerodynamic investigation; however, SimScale’s online platform permitted ongoing development of the aircraft from remote locations, with results effectively shared digitally.

Moving forward, the team hopes to finally manufacture and test the aircraft designed over the coming year to assess its validity. For the next steps, Brunel University hopes to compete in the 2021 edition of the IMechE UAS Challenge. Significant regulatory reform dictates significant variation to mission specification, weight, and dimensions necessitating blank paper design. The team plans to share lessons learned throughout the previous design cycle to permit the rapid development of the new Brunel entry.

If you enjoyed this SimScale student success story, check out more recent success stories here:

- SimScale Formula Student Success Story: Dynamis PRC

- SimScale Student Success Story: Formula Manipal

- SimScale’s Student Ambassador Holds Biomedical Engineering Workshop