Battery simulation has become indispensable in the design and development of modern battery systems, which power everything from electric vehicles (EVs) to renewable energy grids and consumer electronics. The complexity of these systems—where thermal management, structural integrity, and mechanical stability are all tightly interwoven—demands precise and reliable simulation tools. This is where battery modeling software plays a crucial role, allowing engineers to virtually test and refine battery designs long before physical prototypes are constructed.

SimScale, a cloud-native platform, offers comprehensive solutions for battery simulation, enabling engineers to conduct detailed analyses across multiple domains. By leveraging SimScale’s powerful simulation capabilities, engineers can optimize battery designs to enhance performance, extend lifespan, and ensure safety, all while reducing costs and accelerating time-to-market. As battery technology advances, the ability to accurately simulate and optimize these systems is becoming an essential part of the engineering workflow.

SimScale’s Battery Simulation Solutions

SimScale’s cloud-native platform is designed to tackle the challenges of modern battery design with precision and efficiency. Leveraging AI-powered simulations, SimScale provides engineers with advanced tools to analyze and optimize battery systems across key areas such as thermal management, structural integrity, and vibration minimization.

The combination of cloud-native accessibility and AI-driven insights enables teams to run complex simulations faster and more accurately, ensuring that potential issues are identified and addressed early in the design process. This approach not only enhances the performance and safety of battery systems but also accelerates development timelines and reduces costs. Here’s how SimScale’s battery modeling software supports the optimization of battery designs:

Thermal Management and Cooling

Thermal management is a critical aspect of battery design, especially for EVs, where maintaining optimal operating temperatures is vital for safety and performance. Batteries generate significant heat during operation, and without effective cooling, they risk overheating, which can lead to reduced efficiency, faster degradation, or even catastrophic failures like thermal runaway.

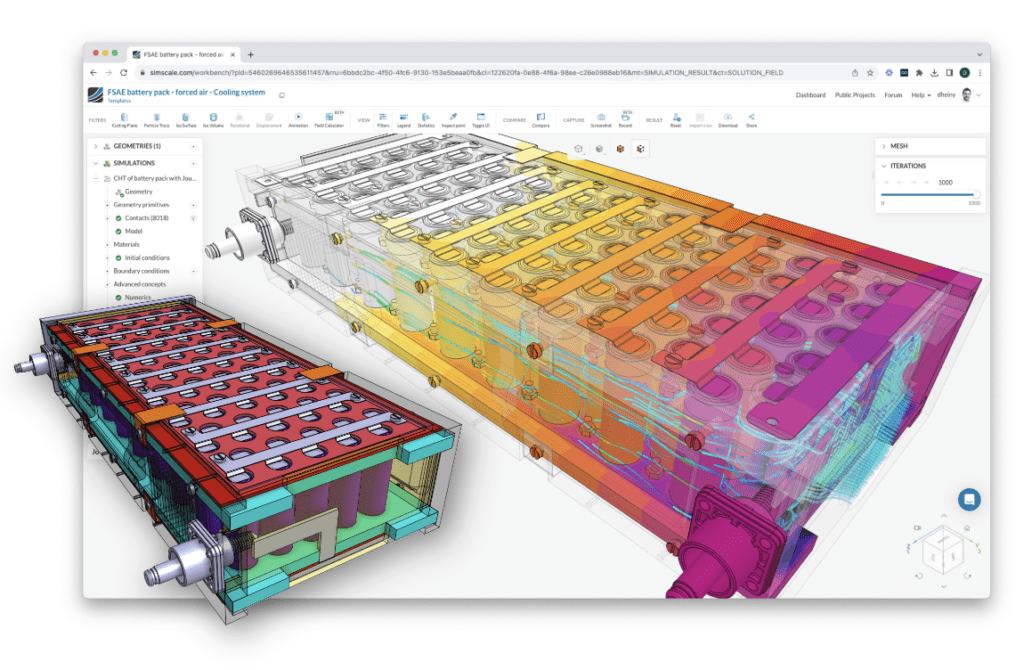

SimScale’s thermal simulation tools empower engineers to address these challenges by providing detailed insights into heat dissipation within battery packs. With SimScale, engineers can model different cooling strategies—such as liquid cooling, air cooling, and thermoelectric cooling—to identify the most effective approach for maintaining safe operating temperatures. The platform’s conjugate heat transfer (CHT) solver enables a comprehensive analysis by simulating the interaction between solid and fluid domains, allowing engineers to evaluate the performance of cooling channels, optimize coolant flow rates, and identify potential hot spots early in the design process.

By simulating various thermal scenarios, engineers can refine their designs to ensure that batteries operate within safe temperature ranges, improving overall efficiency and extending battery life. One example of using SimScale to enhance battery cooling is Bold Valuable Tech. Using SimScale’s cloud-native simulation, they were able to parameterize their battery cooling design by running 100+ simulations in a short period of time and come up with valuable solutions for their high-end motorsport customers. This ability to simulate, test, and iterate quickly on different cooling designs makes SimScale an invaluable tool in the battery design process, helping to mitigate risks and enhance the reliability of battery systems.

“The difficulties in accurately predicting the thermal behavior and pumping losses in the cooling system were only possible to tackle using CFD tools. The main advantage we find in simulation is the speed at which we can try different ideas and design parameters.”

Bernat Carreras, Director at Bold Valuable Technology

Structural Analysis and Vibration Minimization

Maintaining the structural integrity of batteries is essential to ensure long-term reliability and safety. Batteries in EVs, for example, are regularly subjected to vibrations and mechanical loads, which can induce stress, cause wear and tear, and potentially lead to component failure. This risk is especially high in automotive applications, where batteries endure constant vibrations due to road conditions and vehicle operation.

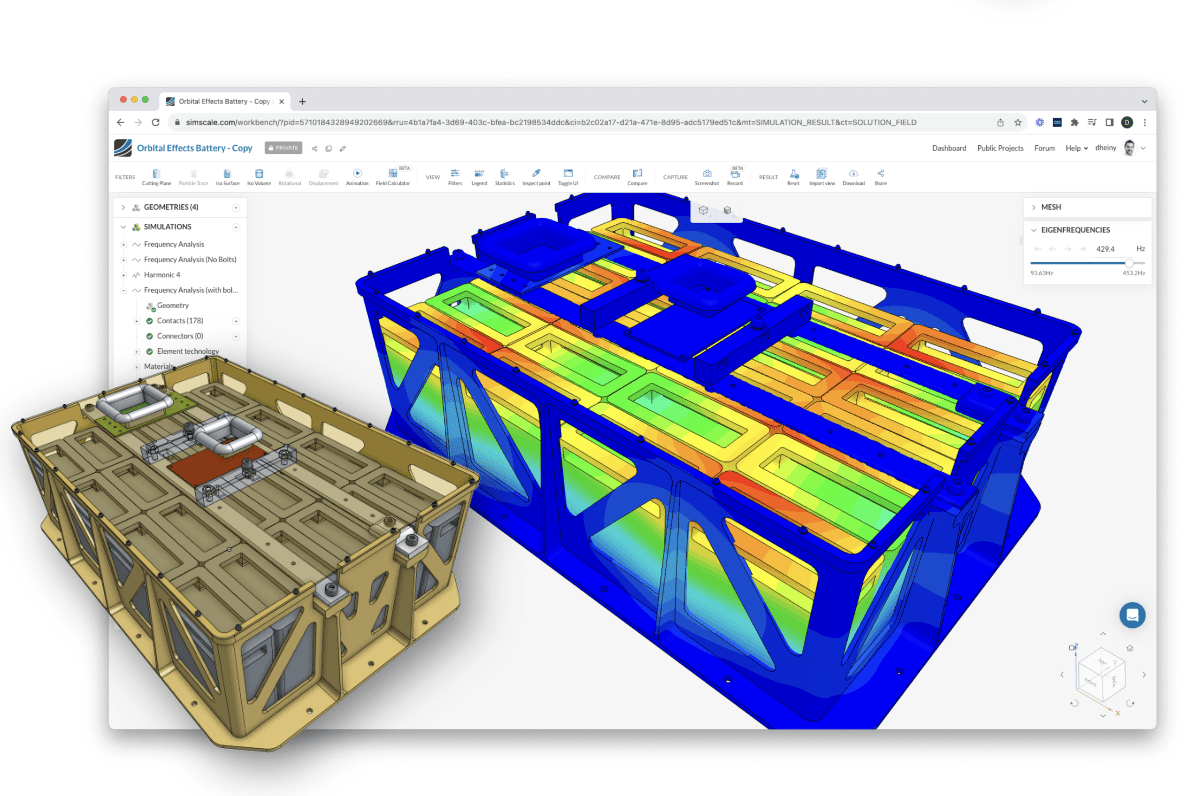

SimScale offers comprehensive finite element analysis (FEA) tools for battery pack simulation, enabling engineers to perform detailed structural analysis. By utilizing these capabilities, engineers can evaluate how a battery pack responds to vibrations and mechanical loads, identifying potential weak points that could compromise its integrity. They can simulate the effects of vibrations on battery components, allowing for targeted reinforcement during the design stage and effectively preventing mechanical failures.

For example, in a SimScale case study, engineers conducted a vibration analysis on an EV battery pack to assess its response to operational stresses. The approach involved examining whether any resonance modes existed within the test frequency range (7 Hz to 200 Hz) and assessing the structure’s response under varying loading conditions. The simulation helped identify potential resonant behavior and pinpoint areas where peak stresses and deformations were likely to occur.

Armed with this information, engineers could make targeted design changes to improve the performance of the battery pack before physical testing. By reinforcing these areas, the engineers were able to design a battery pack that better withstood the rigors of real-world driving conditions and complied with the UN 38.3 standard. This structural reinforcement not only improved the durability of the battery pack but also extended its lifespan, ensuring the safety and reliability of the vehicle.

This process is crucial for delivering robust and dependable battery systems that perform reliably in the demanding environments typical of automotive applications.

Multiphysics Integration

Battery systems involve complex interactions between thermal and structural processes. A holistic approach to battery design requires integrating and simulating these different physical domains in a unified workflow. SimScale’s cloud-native platform offers advanced multiphysics simulation capabilities, allowing engineers to analyze these interactions simultaneously. This approach provides a deeper understanding of how different factors within a battery system influence one another, leading to more robust and optimized designs.

For instance, engineers can use SimScale to model the effects of thermal expansion on the structural integrity of a battery pack. This type of analysis is crucial because thermal expansion can introduce mechanical stresses that, if unaddressed, may lead to deformation or even failure of the battery components. By integrating thermal and structural simulations, SimScale’s battery modeling software enables engineers to identify these risks early in the design process and make necessary adjustments to reinforce the design.

The platform’s cloud-based nature also allows for scalable and efficient simulations, leveraging high-performance computing (HPC) resources to handle complex multiphysics calculations. Engineers can run multiple simulations in parallel, iterating quickly on designs and making data-driven decisions without being constrained by local computational resources. This capability significantly accelerates the development process, reduces the need for costly physical prototypes, and helps ensure that the final battery design performs reliably under real-world conditions. By enabling early-stage, high-fidelity simulations, SimScale empowers engineering teams to improve product performance and reduce time-to-market.

For more details on SimScale’s multiphysics simulation capabilities, you can explore our recent whitepaper on Multiphysics Engineering Simulation in the Cloud.

Advantages of Using SimScale for Battery Simulation

SimScale’s platform offers several advantages for battery design optimization, combining cloud-native accessibility with AI-powered capabilities to enhance the engineering process. These features make SimScale a powerful tool for engineers aiming to improve battery performance, reliability, and safety. Here’s how SimScale stands out:

- Accuracy and Reliability: SimScale’s platform provides high accuracy in simulations, which is crucial for making informed design decisions. The AI-powered predictive capabilities enable the platform to deliver predicted results almost instantaneously based on a vast data set available in SimScale’s cloud-native database. This allows engineers to quickly assess design changes and make data-driven decisions with confidence. Whether optimizing thermal management systems or reinforcing structural components, these simulations help predict real-world performance, reducing the need for multiple physical prototypes and minimizing the risk of unexpected failures.

- Scalability and Accessibility: A key strength of SimScale is its cloud-native platform, which allows for scalable, in-parallel simulations that can handle complex models of battery designs and large data sets without the need for expensive on-premise hardware. The integration of AI further enhances scalability by enabling faster simulation runs and more efficient resource allocation. Engineers can run detailed simulations from anywhere, facilitating real-time collaboration among teams across different locations. This accessibility and AI-enhanced efficiency make it easier to integrate simulation into the design process, speeding up development times and reducing costs.

- Cost-Effectiveness: Traditional battery simulation tools often require a significant upfront investment in hardware and software. SimScale, leveraging both cloud-based and AI-powered technologies, eliminates these costs, making advanced battery simulation tools accessible to companies of all sizes. The predictive AI capabilities further reduce costs by allowing engineers to perform more design iterations in less time, leading to faster optimizations and reduced time-to-market. In addition, SimScale’s speed, accuracy, and ease of use facilitate significant cost savings for organizations and engineering teams. Hear from RLE International on their success with SimScale.

- User-Friendly Interface: SimScale is designed with usability in mind, offering an intuitive interface that lowers the barrier to entry for engineers at all experience levels. The platform’s AI capabilities simplify complex tasks and provide instant predictive feedback, making the simulation process more accessible even for those who are not experts in every aspect of simulation. Additionally, SimScale offers extensive support resources, including tutorials, webinars, and a vibrant community forum, helping users quickly become proficient and maximize the efficiency of their battery simulations.

Applications of Battery Simulation Across Industries

SimScale’s platform offers versatile tools that cater to the specific needs of different sectors, ensuring that engineers can design batteries that meet the unique demands of each application. Here are some of the key industries where battery simulation is particularly impactful:

- Automotive Industry: Battery simulation is critical in the automotive industry, particularly for EVs. Engineers need to design batteries that deliver high performance and withstand the rigors of daily use, including exposure to extreme temperatures and constant vibrations. SimScale’s battery simulation tools allow automotive engineers to optimize battery designs for these conditions, ensuring safety, reliability, and longevity.

- Renewable Energy: In renewable energy systems, efficient and reliable batteries are essential for storing and distributing energy. Battery simulation helps optimize the design of energy storage systems, ensuring they can handle the demands of solar and wind power generation. By simulating different charging and discharging scenarios, engineers can design batteries that maximize energy efficiency and lifespan.

- Consumer Electronics: For consumer electronics, battery design must balance performance with compactness and safety. SimScale’s battery simulation tools help engineers optimize battery designs to meet these requirements, ensuring the final product is both powerful and safe to use. This is particularly important in devices like smartphones and laptops, where battery performance directly impacts user experience.

Conclusion

Battery simulation is a critical tool in modern engineering, enabling the optimization of battery designs across thermal and structural domains. SimScale offers a comprehensive, cloud-native platform that integrates these simulations into a unified workflow, enhanced by AI-powered predictive capabilities. This combination gives engineers the tools they need to iterate rapidly, optimize designs more effectively, and confidently make data-driven decisions. By leveraging SimScale’s advanced simulation and modeling capabilities, teams can significantly reduce development costs, shorten design cycles, and deliver high-performance batteries that meet the evolving demands of today’s technologies.