As automakers transform, so must suppliers. The industry’s future won’t wait: automotive suppliers that don’t adapt will be left behind as OEMs turn to faster, more agile partners.

Timelines are shrinking, and OEMs expect results—faster, cheaper, and more innovative than ever before. With electrification, clean mobility, and digitalization reshaping the automotive industry, the pressure to innovate and deliver has never been more intense. Government regulations, shifting consumer expectations, and fierce competition are forcing suppliers to rethink their entire approach. Those who act now have an opportunity to lead, meet evolving OEM demands, and thrive in the new era of automotive engineering.

With the EU’s commitment to scale up hydrogen mobility by 2030 [1] and US companies now mass-producing fuel cells after years of development [2], the competition and demand in the automotive market are only intensifying. The same holds true for electric vehicles (EVs). Even as the U.S. government eases its 2030 EV sales targets in response to automaker pressure [3], the demands on automotive suppliers remain unrelenting.

Shrinking timelines and bottlenecks in RFQ/RFP responses and engineering projects are pushing the pressure to innovate and deliver faster to a breaking point—suppliers must transform now or risk falling behind.

Is there a way for suppliers to escape this mounting pressure and meet these demands head-on? Some have already found a way with cloud-native simulation. Will you be next?

Addressing Bottlenecks and Shrinking Timelines

One of the biggest obstacles suppliers face today is their reliance on traditional, centralized CAE simulations, where validation can take months. With RFQ timelines shrinking to as little as two weeks, these delays are costing suppliers valuable opportunities and straining their ability to meet market demands. To stay competitive, suppliers need to drastically reduce simulation lead times and accelerate their ability to deliver.

This challenge is compounded by traditional simulation bottlenecks such as long setup times, reliance on specialized hardware, and the need for dedicated simulation teams, which delay validation results and limit the ability to innovate quickly—something increasingly critical in today’s fast-paced market.

To remain competitive, suppliers must reduce product development time, ensure first-time accurate results, and provide cost-effective solutions. Simulation workflows are vital in meeting these goals, but only when they can adapt to faster timelines. Many engineering managers have told us that simulation lead time remains one of their most critical bottlenecks, directly contributing to missed opportunities.

Simulation Lead Time: The Latent Bottleneck

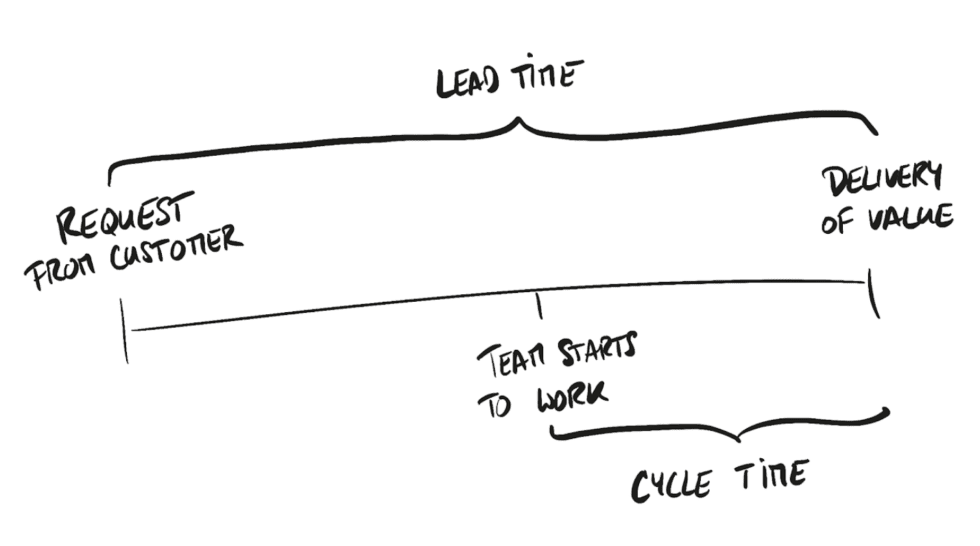

Simulation lead time refers to the period from the moment an engineer requests a simulation to when the results are received. This differs from simulation cycle time, which begins when the simulation team starts processing the request. The gap between these two times—lead time and cycle time—directly impacts how many design iterations engineers can complete.

Engineers would always seek to simulate as many design variants as necessary to maximize the quality of the RFQ response. However, centralized CAE workflows often run one simulation at a time, restricting engineers to fewer iterations and limiting their ability to fully explore alternative designs. This limitation can reduce the quality of RFQ responses, which can have a knock-on effect, leading to missed deadlines, failure to meet customer expectations, and, eventually, loss of revenue and market share.

While simulation lead time remains a critical bottleneck for many, forward-thinking suppliers have drastically reduced it by adopting cloud-native simulation solutions. These companies can now deliver faster results, meet growing market demands, and stay ahead of the competition. Here’s how.

The Solution: Decentralized, Cloud-Native Simulation

Conventional, centralized simulation has been the norm for decades in the automotive industry, proving effective when simulation experts had time to run simulations for a single design variant. However, that’s no longer the reality today. With shrinking timelines and increasing customer demands, centralized simulations can no longer keep pace. Cloud-native simulation offers a transformative solution, helping engineering teams innovate faster.

By leveraging the power of cloud computing, cloud-native simulation decentralizes simulation across the enterprise while maintaining quality control with the simulation experts. It frees simulation from the limitations of local hardware, transforming it from a validation step at the end of the design cycle to an integral part of the entire process. Design and program engineers can simulate early, optimize faster, and explore a wide range of design variants—all in real time using proven methods developed by the simulation team. With no hardware limitations, simulations can run in parallel at any scale, enabling design space exploration. This cuts the simulation lead time significantly. In fact, it eliminates the bottleneck altogether.

By decentralizing simulation processes across different teams while maintaining central simulation governance, automotive suppliers empower design engineers to iterate rapidly. This simulation-driven design approach enables informed decisions throughout the design cycle and drastically reduces simulation lead time. SimScale’s next-generation simulation platform addresses these challenges by enabling early and intensive simulation adoption, reducing lead times from weeks to just one day without compromising quality.

Ready to revolutionize your simulation processes? Get in touch with us, request a demo, or sign up and try it yourself—directly in your web browser, with no installation and no hardware limitations.

Whitepaper: Real-Time Automotive Design & Simulation in the Cloud

Learn more about how you can optimize your automotive design process with SimScale and get industry insights for free.

Simulation-Driven Design Empowering Automotive Suppliers

The automotive industry is in a complex transition period, driven by the imperative to innovate faster and more efficiently. Embracing cloud-native simulation deployment would be an easy solution to a complicated problem, especially for automotive suppliers seeking to thrive in this dynamic space.

By minimizing simulation lead time and embracing a culture of simulation-driven design, suppliers can unlock new realms of innovation and maintain a strong presence in this competitive market.

If you’re interested in learning more about cloud-native simulation, get in touch with us, request a consultation below, or simply sign up and try it for yourself. It works online in your web browser – no installation required, no hardware limitations. Also, check out our blog post on The Automotive Race to Innovation & Efficiency.

References

- Diamante, O. S. (2023). A new dawn for hydrogen mobility in Europe. Petron Plaza. https://www.petrolplaza.com/news/32614

- Parkes, R. (2024). Ten years in the making | GM and Honda begin mass production of hydrogen fuel cells at Michigan factory. Hydrogen Insight. https://www.hydrogeninsight.com/transport/ten-years-in-the-making-gm-and-honda-begin-mass-production-of-hydrogen-fuel-cells-at-michigan-factory/2-1-1588982

- Shepardson, D. (2024). US to soften tailpipe rules, slow EV transition through 2030. Reuters. https://www.reuters.com/business/autos-transportation/biden-administration-relax-ev-rule-tailpipe-emissions-ny-times-2024-02-18/