While knowing your design tools is essential, taking the time to create a good strategy in the design process will pay off many times over later on. This blog post will cover five most common (but not necessarily the five most important) mistakes in the industrial design process.

Mistake 1: Not Preparing for the Design Work

Based on my experience, the very first mistake is not preparing yourself for the upcoming design project. Whether it is a small task or a month-long engineering project, taking the appropriate time to sit down and plan ahead is very beneficial.

If you carry out CFD or FEM simulations, you can ask the following questions:

- Literature research: how have other engineers solved the problem? Are there templates or best practices for my problem?

- Are there quality constraints for my work to be delivered?

- Writing down the exact goal of the project: What do we want to look at?

- Drafting a plan of attack: What is the geometry preparation, meshing, solving and post-processing strategy?

- What are the possible pitfalls? Where can my design process get stuck and from whom can I get help to proceed further?

Taking 10-30 minutes to plan these steps before every project makes the whole process more efficient, productive, and enjoyable.

Mistake 2: Over-Constraining the Design Exploration

Another common mistake in industrial design is when the project manager or the design engineer over-constrains the design space. It means that he or she sets too many limitations on the product, for example:

- Too low of a weight

- Unrealistic size

- Expected performance is too high

- And, of course, too of a low price

It is clear that a high-quality product cannot be built under very low-cost constraints. Additionally, making a product lightweight while prescribing a high mechanical load capacity is unrealistic—the product will break sooner or later.

Another example from fluid dynamics could be the lift vs. drag game. For example, when the engineer wants to maximize lift on a wing profile to improve high speed in the Formula 1 braking effect, the drag will also increase. The latter will be a disadvantage at high-speed sections and accelerations. Prescribing lift forces that are too high will result in a bad performance in other aspects of the product functionality.

Mistake 3: Not Using CAE Technology

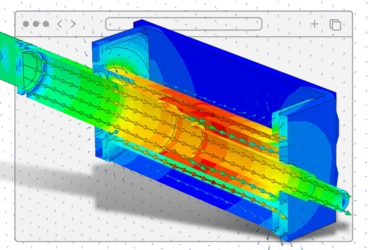

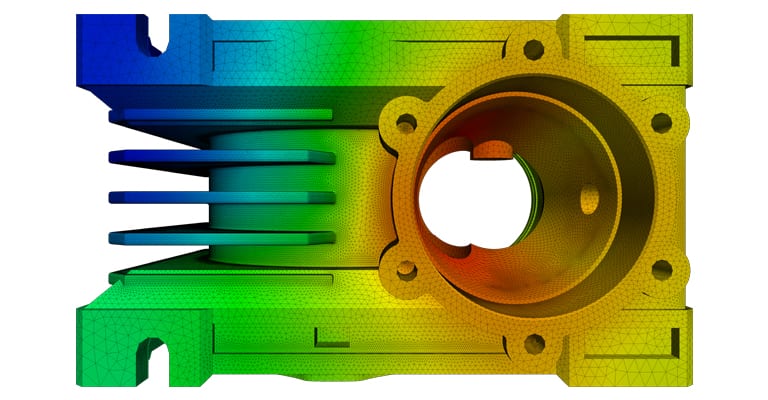

Closely related to mistake two is not using CAE tools (mostly computational fluid dynamics and finite element methods) is also a big mistake. Thanks to open-source software and cloud-based simulation platforms like SimScale, simulation is available to more and more people every day—especially those who are willing to learn!

The biggest advantage of using CAE simulation is the design space exploration. This is exactly the area where numerical analysis can tell us how much the weight of the product can be reduced in order to stay above the breaking limit. Similarly, running a CFD simulation can help us compare lift and drag values of a Formula 1 wind section, so we can make a better decision about the angle of attachment or wing profile, for instance.

While during the industrial design process the functionality and user-friendliness of the product have to be kept in mind, and costs are very important too. Your product design with CAE allows you to keep costs down, invest more time and money, develop a better product, and be more competitive.

Another important consequence of not using a CAE tool is that without it, you have to make decisions based on (semi-) empirical data. That is, an engineer can run a preliminary design calculation on a centrifugal blower, but the performance can be dozens of percentages off the real performance. CAE tools can decrease this uncertainty by an order of magnitude and can provide a deeper insight into the physical quantities and qualities of the product.

Download this case study for free to learn how the SimScale cloud-based platform was used to investigate a ducting system and optimize its performance.

Cloud-Native Simulation for Industrial Machinery Manufacturing

Our latest eBook explores how cloud-native simulation is transforming the challenges of industrial machinery manufacturing into opportunities. Download it for free by clicking the button below.

Mistake 4: Running Too Many Prototype Tests

Also related to the previous point, building and testing too many prototypes is very inefficient.

Both building and testing preliminary products cost more and take more time than even a complex CAE modeling. In most cases, only building prototypes at the end of the industrial design workflow is the most effective way to create a high-performing product. Conducting an experiment after a series of CFD of FEM analyses can validate your numerical models as well as increase your confidence in them.

Mistake 5: Not Managing the Industrial Design Process

Project management is of critical importance in almost every task in engineering or at any company. Even if you are a small consultancy, managing every aspect of your work will get you to your goal much faster. But what do you need to manage if you are designing a product from scratch? And what if you are improving your existing product?

- Human Resources Management. This includes managing your staff if you have any. Proper distribution of the design tasks to the right person will improve the timeline.

- Hardware and Software Resources Management. If your design process involves either physical testing and/or virtual simulations, you can avoid long waiting times by planning ahead.

- Time and Schedule Management. Setting milestones for the sub-tasks will provide external motivation for you and your team. It will also make you focus on the most important things!

- Budget Management. All the above actions will have consequences for the design budget. Carefully estimating and—if necessary, reducing your budget—for example, by using cloud computing—will improve the ROI of your work.